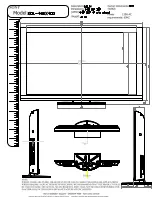

EN-40 7000 Series Indicators

mMENU

MENU LOCK

L.mMENU

RESET

YES

rESEt

NO

L.mMENU

LOCK CAL

ON

L.CAL

OFF

L.mMENU

LOCK SETUP

ON

L.SEtUP

OFF

L.mMENU

LOCK MODE

ON

L.mMOdE

OFF

L.mMENU

LOCK UNIT

ON

L.UNIt

OFF

L.mMENU

LOCK READOUT

ON

L.rEAd

OFF

3.12

Menu Lock Menu

Use this menu to prevent unauthorized changes to menu settings. When the security switch is set to

ON, the locked menus can be viewed but not changed.

3.12.1

Reset

Reset the Menu Lock menu to the factory defaults. Factory default settings are shown in bold.

NO

= not reset

YES

=

reset

NOTE:

Settings for Legal for Trade controlled menu items are not reset.

3.12.2

Lock Calibration

Set the status.

OFF

= the Calibration menu is not locked.

ON

= the Calibration menu is locked.

3.12.3

Lock Setup

Set the status.

OFF

= the Setup menu is not locked.

ON

= the Setup menu is locked.

3.12.4

Lock Readout

Set the status.

OFF

= the Readout menu is not locked.

ON

= the Readout menu is locked.

3.12.5

Lock Mode

Set the status.

OFF

= the Mode menu is not locked.

ON

= the Mode menu is locked.

3.12.6

Lock Unit

Set the status.

OFF

= the Unit menu is not locked.

ON

= the Unit menu is locked.

Summary of Contents for T71P

Page 1: ...7000 Series Indicators Instruction Manual T71P T71XW ...

Page 2: ......