80

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

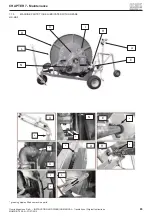

CHAPTER 7 - Maintenance

Removal of the wheels

The wheels may only be replaced by qualifi ed and authorised technical personnel.

•

Handle all parts with the utmost care.

•

Do not place your hands, fi ngers and limbs between parts.

•

Wear safety clothing and approved PPE such as goggles, gloves and safety shoes.

•

Ensure the tyre is completely defl ated before starting removal.

•

Place the machine on a fl at surface and block it with the parking brake.

•

Place wedges under the wheels that remain in contact with the ground.

Before proceeding with any subsequent operation, completely defl ate the tyre, also removing the middle body of the valve for more complete and

safer air removal.

With the wheel to be replaced still in contact with the ground, partially loosen its fi xing screws or nuts.

Then lift the machine until the wheel is suffi ciently detached from the ground and secure the trolley by placing it on adequate and stable supports.

Proceed with full removal of the wheel's screws or nuts and extract it from the hub.

7.4.2.6

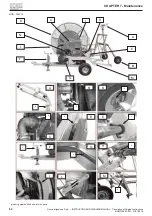

WHEEL RIMS

Fitting the rims

Upon fi tting check integrity and conformity of the components used:

•

Do not use or repair damaged or warped wheels.

•

Do not repair rims or discs by welding.

•

Replace faulty elements with others of the same type, profi le and size.

•

Clean all coupling surfaces and protect them from rust.

•

Use a rubber mallet to assemble the parts.

•

Spread a solution of soap in water or specifi c grease for tyre fi tting on the rim groove and on the base of the tyre.

•

Never use petroleum based lubricants or antifreeze.

•

Ensure the rim is of suitable size for the wheel.

•

Lubricate the parts of the wheel in contact with the heel and the inner tube.

Removing rims from the wheels

Prior to starting disassembly of a wheel of the vehicle, ensure the tyre is completely removed and ensure the tyre casing and/or rim are not damaged.

•

Remove the nuts fastening the two parts of the rim.

•

Loosen the heel of the tyre from the side fl ange.

•

Remove the rim from the wheel.

•

Remove the inner tube.

7.4.2.7

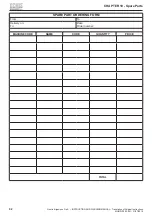

SCREW TIGHTENING TORQUES

During maintenance procedures it is often required to tighten steel screws of varying types and sizes with a torque wrench.

The following tables show the maximum tightening torque to be used according to the resistance of the material and screw size.

TIGHTENING TORQUES FOR STEEL SCREWS WITH ISO THREAD

Maximum tightening torques for metric screws with friction coeffi cient 0.14

Ø

SCREW

HEXAGON

new

►

6.8

8.8

10.9

12.9

old

►

6S

8G

10K

12K

ø screw

hexagon

Pitch

Pitch

Pitch

Pitch

Pitch

coarse

fi ne

coarse

fi ne

coarse

fi ne

coarse

fi ne

coarse

fi ne

mm

mm

mm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

M6

10

1

-

7.8

-

10

-

15

-

18

-

M8

13

1.25

1

19

20

25

27

35

38

42

46

M10

17

1.5

1.25

37

39

50

53

70

74

84

89

M12

19

1.75

1.5

36

67

85

89

119

125

143

150

M14

22

2

1.5

101

111

135

148

190

208

228

250

M16

24

2

1.5

159

170

212

226

298

318

357

382

M18

27

2.5

2

218

233

290

310

402

436

490

523

M20

30

2.5

2

310

327

413

436

580

614

697

736

M22

34

2.5

2

426

448

568

597

798

840

958

1008

M24

36

3

2

535

586

714

781

1004

1098

1204

1317

M27

41

3

2

788

855

1050

1139

1477

1602

1772

1923

M30

46

4

2

1072

1193

1429

1590

2009

2236

2411

2648

M33

50

3.5

2

1456

1602

1941

2136

2729

3004

3275

3605

M36

55

4

3

1873

1989

2497

2652

3511

3730

4213

4476

M39

60

4

3

2431

2573

3242

3430

4559

4824

5471

5789

- The torque settings shown in the table correspond to 80% of the yield point

- For self-locking nuts or ring nuts the torque setting shall be increased by 15% .

- The settings shown are indicative

Summary of Contents for MR

Page 99: ......