19

Please keep these assembly, operating and maintenance instructions as long as you use the product!

GB

Wall plugs / Frame plugs

Name

Approval

certificate

Fischer wall plugs GB

for aerated concrete with special matching

screws to fasten, min. Ø 10 mm

Z-21.2-123

Hilti frame plug HRD

with special matching screws for fastening to

façade revetments, min. Ø 10 mm

ETA-07/0219

Fischer frame plug SXR / SXRL

with special matching screws for fastening to

façade revetments, min. Ø 10 mm

ETA-07/0121

Fischer universal frame plug FUR

with special matching screws for fastening to

façade revetments, min. Ø 10 mm

ETA-13/0235

ApolloMEA multifunction frame plug MFR

façade plug with special matching screws for

fastening to façade revetments, min. Ø 10 mm

ETA-07/0337

Hilti frame plug HRD

with special matching screws for fastening to

façade revetments, min. Ø 10 mm

ETA-07/0219

Fischer long-shaft plug SXR

with special matching screws for fastening to

façade revetments, min. Ø 10 mm

ETA-07/0121

Würth plastic frame plug W-UR

with special matching screws for fastening to

façade revetments, Ø 10 mm

ETA-08/0190

Protective boxes

In order to ensure the functioning of single

or double-leaf doors, their protective boxes

should not be removed.

Selection of wall plugs

The following requirements should be

observed when installing:

– Only construction-approved wall plugs

(Ø 10), suitable for substrate usage

should be used.

– Wall plugs do not have to be explicitly

approved for use on fire protection doors.

– Wall plugs must be used with the appro-

priate screws.

– The borehole diameter and depth stipu-

lated in the approval must be respected.

– Dust must be removed from boreholes

before inserting the wall plugs.

– Where working with perforated masonry,

drilling must be done without engaging

hammer action.

– Where the type of wall and frame meas-

urements allow it, approved expanding

steel anchor plugs may be used.

Paint finish

Our frames and door leaves are provided as

standard with a high-quality powder primer.

When adding another coat please note:

– The surface must be sanded and

cleaned.

– It will be necessary to apply one final

coat using 2KPUR solvent-based paint

afterwards.

– Alternatively, one may apply a layer of

2K epoxi primer containing solvents and

then apply a final coat of conventional,

zinc-compatible, synthetic lacquer paint.

– The correct final painting must be

carried out within three months of

assembly. Otherwise we can accept

no liability for corrosion damage.

– Seals, locks and other fittings must not

be overpainted.

Due to the saponification of zinc surfaces

and the resulting reduction in adhesion,

we recommend against overpainting such

surfaces with synthetic lacquers.

To be observed during welding:

Paint must be removed from weld joints

and they must be fitted with a primer that

can be overcoated.

Welding work must always be carried out

so that foam-forming building materials

are never inside the area affected by the

heat of the welding work.

Connecting electrical components:

Electrical connections for devices, such as

door drivers, motorised locks, door closing

mechanisms with locking devices, etc. must

be executed by specialists authorised

according to VDE regulations.

Direct sunlight

Especially where multi-purpose doors used

outdoors are subjected to direct sunlight,

painting surfaces in dark colours may lead

to an elevated rate of heat accumulation on

the surface of the door leaf. This may result

in increased bending or deformation of the

door leaf.

Any deformation due to such painting in

a dark colour and any limitation on the

functioning of the door sealing will not

constitute a ground for any legitimate

complaint.

In such cases we recommend the preven-

tion of radiation from direct sunlight by

construction means (e.g. using canopy

roofs, enclosures or a pale or reflective

coating of paint).

We reserve the right to make technical

changes. All dimensions in mm.

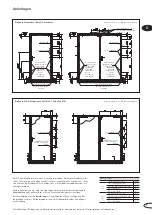

Deviations in precision of wall openings

Approved deviations from wall opening

dimension in accordance with DIN 18100:

Width:

Coordinating size width + 20 mm / – 0 mm

Height:

Coordinating size height + 15 mm / – 0 mm

Where the dimensional tolerances are ex-

ceeded, the correct functioning and stability

of the door can no longer be guaranteed.

Summary of Contents for NovoPorta Premio E-S-1

Page 47: ...13 14 15 18 19 20 21 22 1 2 12 16 17 11 47 ...

Page 49: ...2 1 25 23 24 1 1 2 3 4 5 1 49 ...

Page 51: ...2 5 mm 30 31 1 29 28 27 26 51 ...

Page 53: ...1 2 3 1 2 3 1 1 2 2 3 3 33 34 35 36 37 38 32 53 ...

Page 55: ...41 42 43 44 45 1 1 8 9 4 2 3 7 6 10 5 11 45 5 5 lt 39 40 55 ...

Page 57: ...84 5 45 34 50 48 3 2 1 4 5 6 5 6 7 8 46 57 ...

Page 59: ...47 50 52 55 48 51 53 56 49 54 59 ...

Page 61: ...60 62 65 58 61 63 66 59 64 57 61 ...

Page 63: ...67 70 73 74 68 71 69 72 63 ...

Page 65: ...45 39 48 1 6 8 9 5 10 2 3 4 75 65 ...

Page 67: ...76 77 79 80 81 82 83 78 67 ...

Page 69: ...1 1 5 5 1 1 1 4 3 2 7 6 8 5 9 10 42 53 1 3 2 1 84 85 86 87 69 ...

Page 71: ...1 2 3 1 2 3 1 1 2 2 3 3 1 2 3 4 6 9 6 8 5 11 7 10 42 5 5 88 89 71 ...

Page 73: ...1 9 4 2 3 5 11 10 7 6 8 42 5 5 93 94 90 91 92 73 ...

Page 77: ...1 4 7 3 2 5 8 9 6 42 5 5 100 98 77 ...

Page 79: ...1 9 8 2 7 4 3 6 10 11 5 42 5 5 45 1 7 4 8 2 3 6 5 10 11 9 42 39 max 69 99 100 79 ...

Page 81: ...1 9 7 6 3 10 8 2 4 5 11 12 42 5 5 1 2 1 2 101 81 ...

Page 83: ...1 2 4 3 9 8 5 6 7 10 48 82 100 50 102 103 1 83 ...

Page 85: ...1 10 9 7 4 3 2 6 8 5 11 12 42 5 5 104 85 ...

Page 87: ...1 2 3 4 5 1 2 3 4 105 1 8 4 9 5 6 3 7 2 10 40 45 1 8 11 9 6 6 2 3 7 4 5 10 40 106 107 87 ...

Page 89: ...1 7 6 9 5 6 2 4 8 42 x5 30 31 50 40 108 89 ...

Page 95: ...97 61 1 3 2 6 5 4 7 120 95 ...

Page 97: ...1 4 3 2 6 9 10 5 7 42 39 max 69 1 4 3 2 9 10 5 7 6 42 39 max 69 121 122 97 ...

Page 101: ...1 8 6 5 9 4 2 3 7 42 39 max 69 127 101 ...

Page 105: ...130 131 132 105 ...

Page 107: ...133 135 134 107 ...

Page 115: ...4 1 2 3 4 1 2 3 9 7 2 3 8 4 1 149 150 151 152 6 1 5 115 ...

Page 123: ...1 2 3 4 5 5 167 123 ...

Page 129: ...129 ...

Page 130: ...130 ...

Page 131: ...131 ...