EasyGrid User Guide

10

5

System Overview

5.1

System Overview

The Nortech EasyGrid signal conditioner is design to monitor fiber optic temperature sensors installed

inside high voltage power transformers. Immunity to electrical interference and high dielectric constant

procured by fiber optic sensors allow direct contact with high voltage components. It is the only

technology that monitors the true winding temperature in real-time.

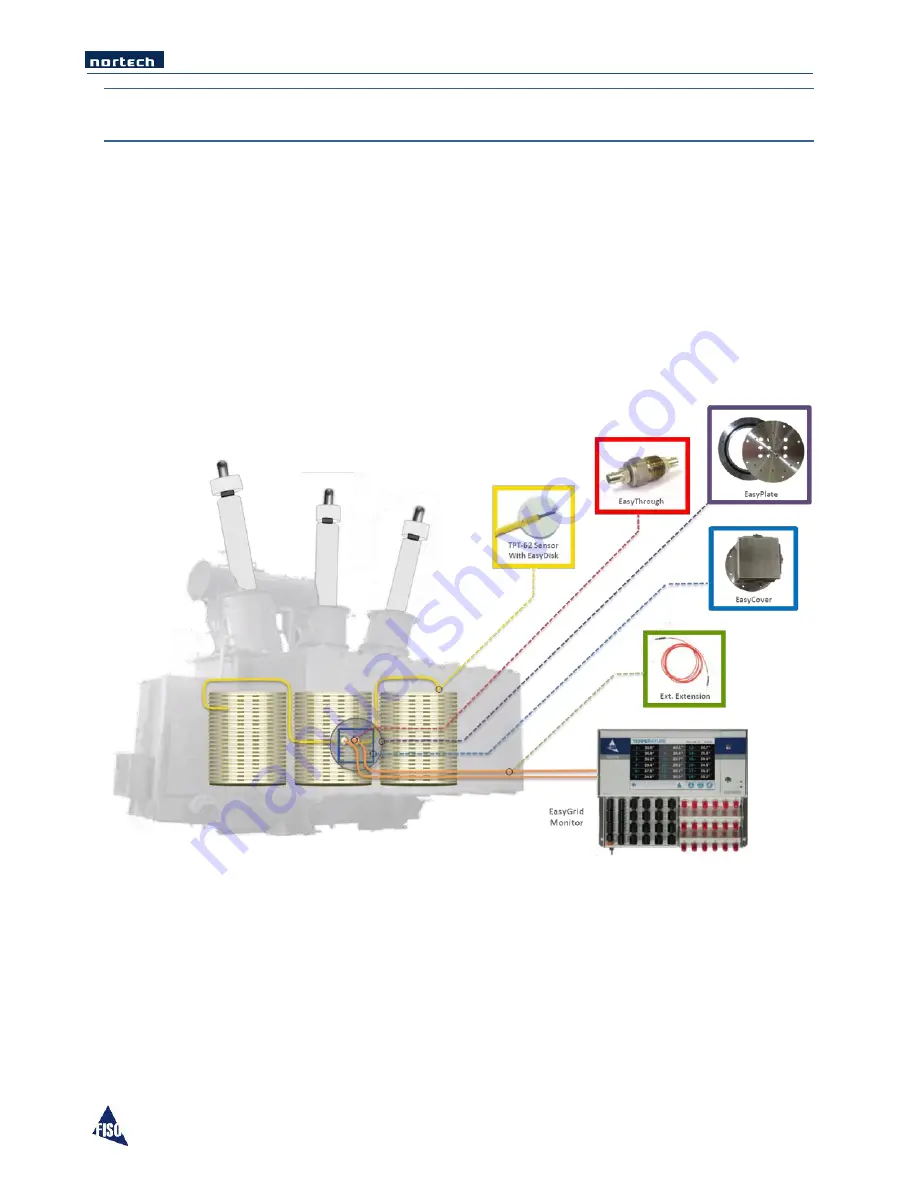

To be functional in its target environment, the Nortech EasyGrid is part of a system that includes the

fiber optic sensors and all the components in between. The figure below gives you a general idea of a

typical installation.

In this section we will describe the different component required to have a complete winding

temperature measurement system. Note that all components specified in this document are available at

FISO; contact your sales representative if you need more details.

Summary of Contents for EasyGrid V1

Page 1: ...EasyGrid User Guide i Nortech EasyGrid User Guide MAN 00084 R 10 0 ...

Page 24: ...EasyGrid User Guide 19 6 Hardware Configuration 6 1 Dimensions ...

Page 97: ...EasyGrid User Guide 92 11 3 Assembly Diagram ...

Page 99: ...EasyGrid User Guide 94 11 4 1 2 Pre Drilling 11 4 1 3 Using the Knockout Punch ...

Page 100: ...EasyGrid User Guide 95 11 4 1 4 Cutting the Cable Slot 11 4 1 5 Inserting the Easy Disk ...