·

27

·

E. Screw off the screw plug of fuel tank to release the fuel and wash it.

F. Brush the air cleaner.

G. Clean the outlook of battery, inspect the specific gravity of electrolyte of battery (1.285). If

necessary, recharge it additionally. Clean away rust on battery poles, and coat them with

grease against corrosion.

H. Clean the oil filter in lift.

I.

Check and adjust the brake.

J.

Check and adjust the travel of clutch.

K .Check and adjust the front wheel toe-in.

III. Technical Maintenance after 500 Accumulated Working Hours

A. Complete the technical maintenance of 500 accumulated working hours.

B. Check the following parts of engine.

a. Check the injection pressure and the condition of atomization of injection element. If

necessary, clean and adjust the injector, or change it.

b. Check the clearance between the spring of valve and the valve (the inlet valve TY395 IT

is 0.35 mm, the exhaust valve is 0.4 mm , and the clearance of inlet valve 490 T is 0.4--0.5

mm) and adjust them.

c. Make sure that tightness of the nuts of cylinder head and the bolts of the connecting rod

and flywheel are fixed well and reliable.

d. Check the seal between the valve and its retainer whether leakage exists. If necessary,

polish it and clean away the accumulated carbon in the gas pipe..

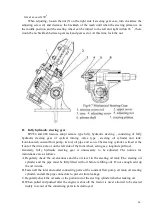

C. Check and adjust the free backlash angle of the steering wheel. It can be adjusted when

necessary.

D. Change the lubricating oil in transmission.

E.

Wash the interior of lift housing , and change the oil.

F.

Check and wash the key pin and its sleeve of the steering knuckle of the front axle. Check

and adjust the clearance of front wheel bearing.

G. Check the wire connection of electrical system, clean away the greasy dirt and rust spot.

IV. Technical Maintenance After 1000 Accumulated Working Hours.

A. Complete the technical maintenance after 500 accumulated working hours.

B. Check the following parts of the engine

a. Clean away the carbon on the cylinder head, check the sealing of the valve (polish it if

necessary). Clean away the carbon on the piston. Check the clearance of the gap of the

piston ring and the wearing of the cylinder of the bearing of the connecting rod and

crankshaft.

b. Check the wearing of cam, pull-rod and rocker-arm.

c. Check the fuel supply uniformity and the advance angle of injection pump. Adjust them if

necessary.

d. Check the moving flexibility of the cooling pump shaft and the seal ring. If there is any

damage, change them.

C. Clean away the incrustation in the cooling system..

Summary of Contents for Benye 35 Series

Page 1: ......

Page 5: ... 4 Appendix Ⅲ 51 Ⅰ Sketch of Transmission System 51 Ⅱ Diagram of Linkage Hitch 52 ...

Page 41: ... 40 ...

Page 43: ... 42 rotating timer steering indicating lights a charging alarm indicating device etc ...

Page 59: ... 58 Appendix Ⅲ ...

Page 60: ... 59 II Dimensional Sketch of linkage System END ...

Page 61: ... 60 ...