·

23

·

adjusted before leaving the manufacturer. It is unnecessary to change them.

Working on farm, the implement should be lifted up before the tractor turns, and lowered

only after it has turned and is running in straight line. The draft control handle does not permit

to lower the implement on hard ground, which could destroy the handle due to high speed

lowering.

The implement mounted on a tractor for a long distance driving, should be locked on the

lifting position by screwing in the shut-off valve adjusting handwheel on the right side of the

lift . The draft and position control handles are put in lowering position (Fig.4-16). The PTO

shaft is in "disengagement" to stop the working of the hydraulic system, and is put back to the

"engagement"

position

after

the

driving. When a tractor is hitched a

trailer and used for transportation , the

lifting arm should be put in lowering

position and the shut-off valve be

screwed in and locked to prevent from

unnecessary wearing.

Notice to screwing in the shut-off

valve. The valve rod nut is used to

lock after screwing in the shut-off

valve.

When

screwing

in

or

unscrewing off the shut-off valve, the

nut should be loosened and returned to

the outer end to guarantee the valve

screwed in completely.

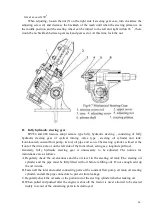

c. Operation of Draft Control Handle .

Draft

control

can

ensure

the

tillage depth and the towing force, mainly used in working on rolling field. Ploughing work

generally adapts this control.

When the draft control handle is put forward, the implement begins to fall down and

penetrate into the earth. After the implement reaches the required depth, the handle moving

has to be stopped and the draft control handle has to be limited by the position-fixed

handwheel (Fig.4--15).The handle is pushed to such a fixed position whenever the falling of

the implement is needed.

d. Operation of Position Control Handle

The distinct feature of the position control is that a implement falls when the position

control handle is pushed forward. The more the handle is pushed , the more the implement falls

down. Against each position of the position control handle , there is a corresponding position

keeping a relevant relation between the implement and the tractor.(Fig.4--15).

The position control is usually used in roto-tilling and other non-farm work, such as

harvesting , lifting bulldozing ,trailer--dumping ,etc. However, it can also be used in ploughing if

the field is comparatively flat and the variation of soil resistance is little. When the implement

has reached the needed depth in ploughing, the position control handle should be limited by a

position-fixed handwheel to keep the implement fall to the same depth every time.

e. Selection of joint point of upper link.

With draft control in controlling tillage depth, the front end of the upper link connects to the

Summary of Contents for Benye 35 Series

Page 1: ......

Page 5: ... 4 Appendix Ⅲ 51 Ⅰ Sketch of Transmission System 51 Ⅱ Diagram of Linkage Hitch 52 ...

Page 41: ... 40 ...

Page 43: ... 42 rotating timer steering indicating lights a charging alarm indicating device etc ...

Page 59: ... 58 Appendix Ⅲ ...

Page 60: ... 59 II Dimensional Sketch of linkage System END ...

Page 61: ... 60 ...