·

25

·

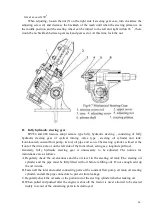

b. Take off the sealing cover and its paper gasket from the oil pump and fasten them.

c. Fix the pulley assy. on the PTO shaft.

d. Push the auxiliary gearshift lever to the neutral position, the main lever in the positions of

Gear I and II (to have the bearing of the I-shaft completely lubricated), the output drive shaft

handle in the engaged position, the PTO shaft handle in low speed positions, and then keep

the pulley running at low speeds.

e. After driving the tractor to a suitable place, shut off the engine and push the PTO shaft handle

to neutral position.

f. Fix the stationary machine, have the pulley in correct position and keep the belt with suitable

tension. If necessary, move the machine or the tractor.

g. Pull the belt by hand to check the installation, and then fix the machine and the tractor.

h. Start the engine to drive the belt. At the

beginning, keep the engine running at low

speed and then check the work of the engine

with running at higher speeds.

i.

While a mechanical group works normally, its

required running speed can be obtained by

adjusting the hand throttle. But it is not

suitable to reduce the running speed too much

because the output is reduced with decreasing

of the running speed. Notice: When the engine

runs , it is always to step down the clutch

pedal .

Summary of Contents for Benye 35 Series

Page 1: ......

Page 5: ... 4 Appendix Ⅲ 51 Ⅰ Sketch of Transmission System 51 Ⅱ Diagram of Linkage Hitch 52 ...

Page 41: ... 40 ...

Page 43: ... 42 rotating timer steering indicating lights a charging alarm indicating device etc ...

Page 59: ... 58 Appendix Ⅲ ...

Page 60: ... 59 II Dimensional Sketch of linkage System END ...

Page 61: ... 60 ...