20

Eng

lis

h (

EN

)

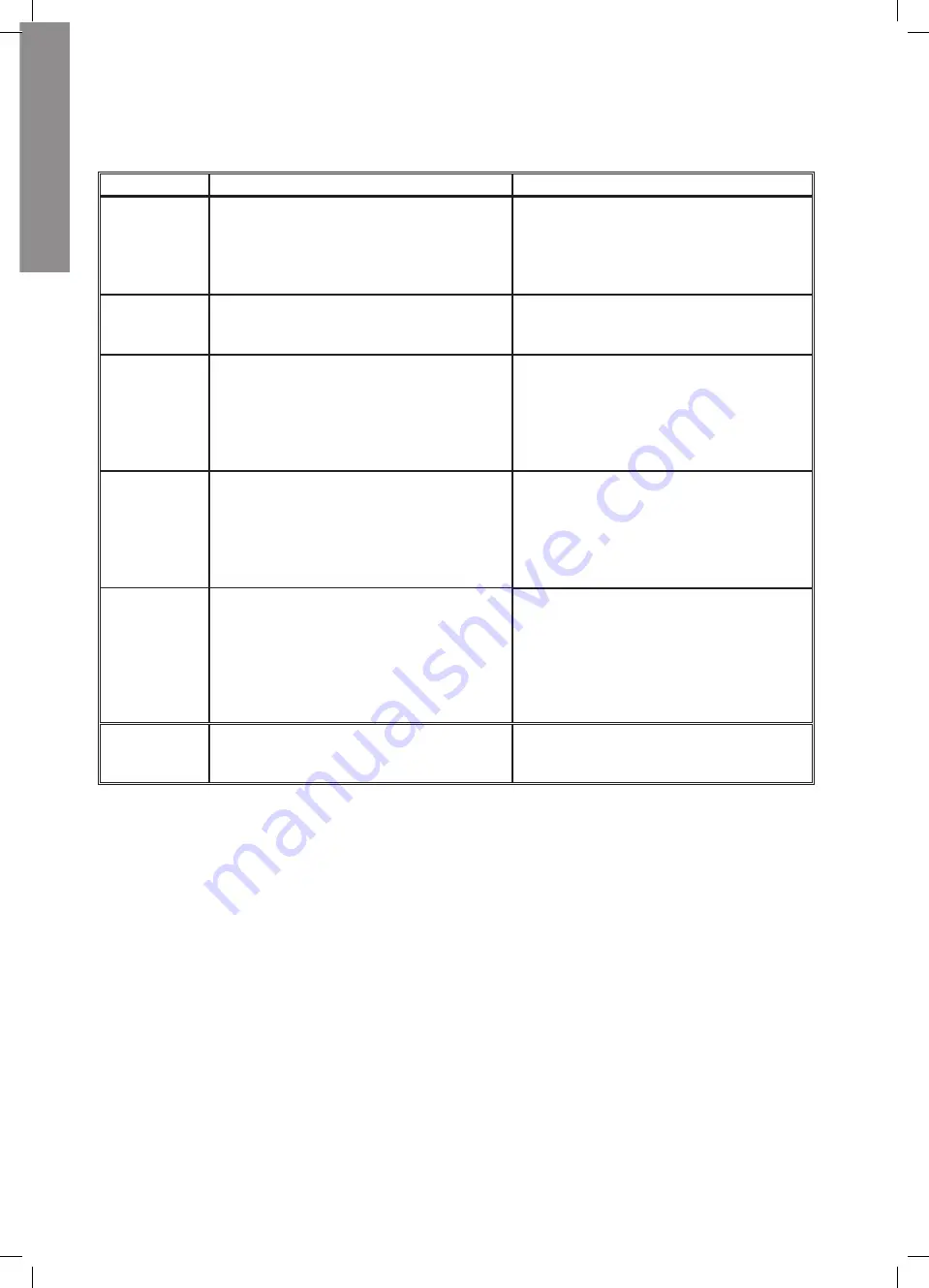

9.8. Trouble Shooting and Remedy

In case of errors/troubles not mentioned above, please contact your local service technician for further assis-

tance.

Fault

Cause

Remedy

The unit does

not start

•

Is there voltage to the unit

•

The unit does not start after reconnecting

voltage

•

Unit starts after changing start up method

•

After reactivating flow start

•

Reconnect voltage

•

Go to setup ->settings menu ->startup

method and set it to pressure

•

Set unit back to flow start in setup menu

•

Try to re adjust flow switch

The "Δ" lamp on

the control panel

is flashing

•

Error messages on display

•

Press "O" wait for a few seconds and

then press "1" on the control panel to

restart the system

No pressure /

too low pressure

•

Insufficient water supply

•

Is the filter clogged

•

Is the pump leaking or making jarring sounds

•

Rinsing nozzle not installed

•

Defect in booster unit

•

No water supply

•

Open water supply valve

•

Clean the filter

•

Call technician

•

Place rinsing nozzle

•

Consult direction for use of booster unit

•

Ensure water supply

Insufficient foam

creation

•

No supply of diluted products

•

Product not suitable

•

Insufficient air supply

•

Air presure in mixing chamber too high

•

Defect non return valve for air

•

Incorrect nozzle

•

Consult directions for use of dosing unit

•

Choose suitable product

•

Provide sufficient air supply

•

Adjust air pressure setting

•

Replace non return valve for air

•

Place foam nozzle 50/200

No foam crea

-

tion

•

No supply of diluted products

•

Product not suitable

•

Air pressure in mixing chamber too high

•

Defect non return valve for air

•

No air supply

•

Non return valve blocked

•

Nozzle of mixing chamber blocked

•

Consult directions for use of dosing unit

•

Choose suitable product

•

Adjust air pressure setting

•

Replace non return valve for air

•

Ensure air supply

•

Clean or replace non return valve

•

Clean nozzle

No spray sani-

tising

•

No supply of diluted products

•

Non return valve blocked

•

Nozzle of mixing chamber blocked

•

Consult directions for use of dosing unit

•

Clean or replace non return valve

•

Clean nozzle

9.9. Service address

Please see the back cover of this manual

Summary of Contents for Hybrid Typhoon

Page 1: ...Hybrid Typhoon Directions for use Gebrauchsanweisung Mode d emploi Instrucciones de uso...

Page 80: ......

Page 86: ...8 2 4 5 6 1 3 7 110004550 Hybrid Typhoon...

Page 88: ...Hybrid Typhoon 1 3 2 4 5 110004554...

Page 90: ...17198_30 1 2 3 Hybrid Typhoon...

Page 92: ...Hybrid Typhoon 110004551 1 2...

Page 94: ...Hybrid Typhoon 1 2 3 4 9 8 7 6 5 10 7 8 12 11 13 110004548...

Page 96: ...Hybrid Typhoon 110004552 1 2 3...

Page 98: ...Installation 658 1435 1011 1107 110004599...

Page 100: ...El diagram 110004767E...

Page 101: ...El diagram...

Page 102: ...El diagram...

Page 103: ...110004775D El diagram...

Page 104: ...El diagram...

Page 105: ...El diagram...

Page 107: ...Pump curve 25 bar 50 Hz...

Page 109: ...Layout Hybrid MU...

Page 111: ......