5

NRXMK Y

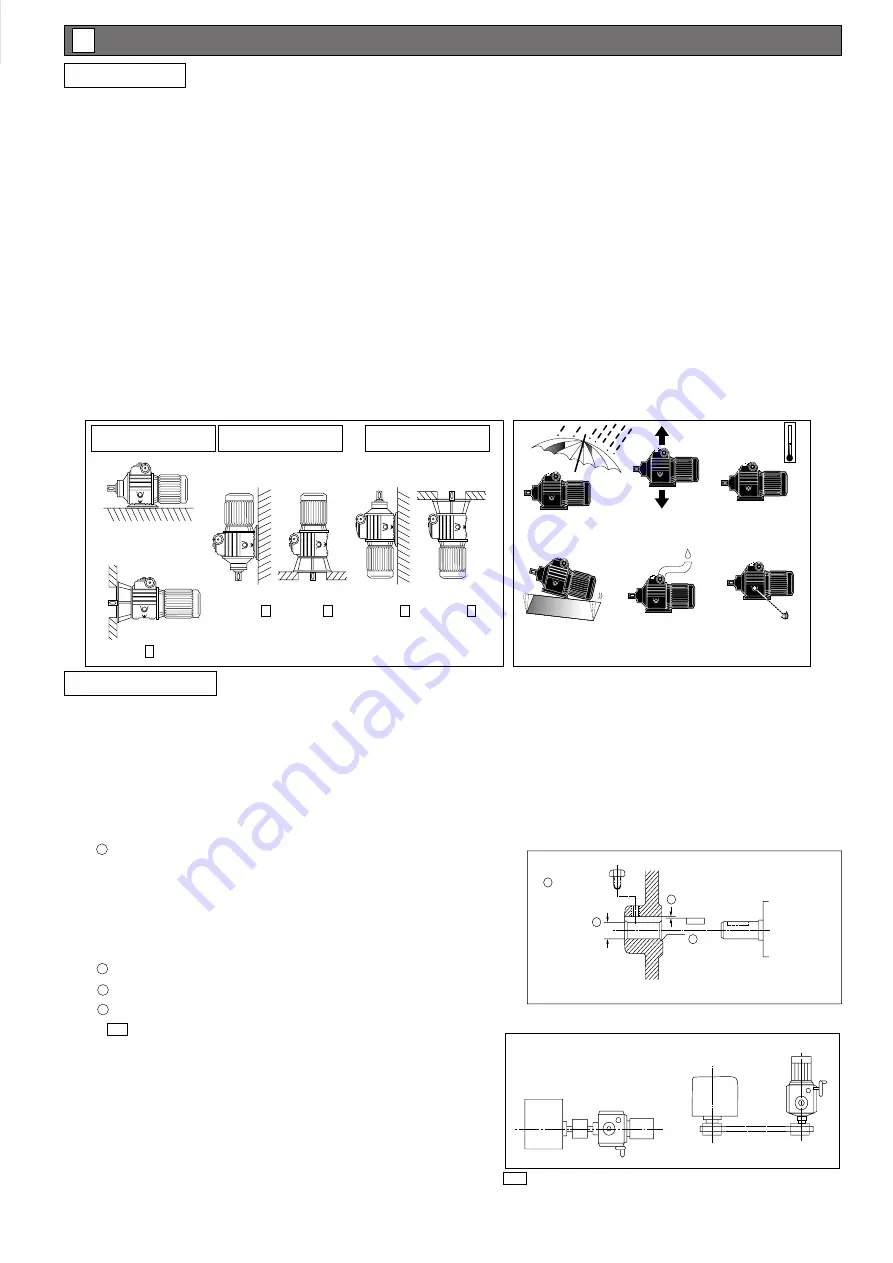

Base type

NRXMK Z

Base type

NRXMK V

Flange type

NRXMK I

Flange type

NRXMK X Flange type

c

b

a

d

2. When connecting the product, do not apply impact force and/or excessive thrust load on the output shaft

(use tapping hole on the output shaft for 11K to 18K).

a

Since the output shaft diameter dimension tolerance of the speed drive has been

set to h6 for 200B to 7500, and m6 for 11K to 18K, set the hole tolerance of the

coupling, pulley, chain sprocket, and gear, which are to be mounted, to H7 for

200B to 7500, and F7 for 11K to 18K. Then, push the output shaft into the hole

by tapping with a wooden or plastic hammer. Pushing the shaft by hitting it hard

could result in damage to bearings and/or the inside of the speed drive.

b Chamfer the hole mouth by approximately 1 mm.

c Make clearance of 0.1 mm to 0.2 mm for the key head.

d Hold and secure the key head using a set bolt.

3.Ensure centering before connection.

■ For connection with a coupling, properly align the speed drive shaft with

the mated machine shaft.

■ For connection with pulley, chain sprocket, and gear, etc., properly make

the speed drive shaft parallel with the mated machine shaft, determine the

correct center line, and fit precisely.

Note : Make the effective diameter of the coupling, pulley, chain sprocket, and gear, etc. at least

five times the output (input) shaft diameter of the speed drive. Be careful not to allow

impact, vibration, and/or excessive thrust load from the machine to apply to the shaft ends.

(For information about allowable shaft weight, refer to the catalog).

1. Allow a sufficient margin when setting the rotating speed and torque.

■ When driving the mated machine at the maximum speed, connect the speed drive so that it also operates at the maximum rotation.

■ For machines of which torque increases at the lower speed (such as those with constant horsepower characteristics), set the maximum torque to be

within the rated torque of the speed drive.

1

NRXMK Base type

30cm

Maintain an ambient

temperature between

0ºC and 40ºC

Make it easy to add

and drain oil

Install horizontally on a

vibration-free bench

Keep from getting wet

Provide sufficient

clearance

Make the oil gauge

easily visible

10cm

1-1 Installation

1-2 Connections

1. Avoid installing the product in a place directly exposed to rain or water.

■ Consult us in advance if you use the product outdoors, or in a place exposed to dust or water.

2.Install the product in an area with an ambient temperature of between 0ºC and 40ºC.

■ If you plan to use the product beyond the above mentioned temperature range (at higher or lower temperature), be sure to consult us.

3.Securely fix the product using bolts on a solid installation bench that is not prone to vibration.

■ Install the horizontal type horizontally, the vertical type (with downward output shaft) and inverted type (with upward output shaft)

vertically. Failure to follow this could result in malfunction due to poor lubrication.

For inclined installation, consult us.

4. Install the product in a way that provides easy access for inspection and maintenance.

■ To make it easy to add and drain lubricating oil, install the product at a level of approximately 10 cm from the floor by securing a top

clearance of approximately 30 cm.

■ When installed the product into machines, place it so that the oil level can be checked externally, and lubricating oil can be easily replaced

using pipes.

[ Output shaft direction and installation direction ] [ Installation conditions ]

Note : The output shaft rotation direction for the speed drive equipped with a

Coronet speed reducer (N11, 17, 29, 35, 47, 59, 71 types) is the same as that

of the input shaft.

Installation

Horizontal type

(with horizontal output shaft)

Vertical type

(with downward output shaft)

Inverted type

(with upward output shaft)

Set bolt

Adjustable

speed drive

Output shaft

Coupling

Pulley

Chain sprocket

Gear

Mated machine

Mated machine

Coupling

Belt, chain, gear

Speed drive

Speed drive

Summary of Contents for RINDCODE NRX Series

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...Address 1 Terada Kohtari Nagaokakyo city Kyoto 617 0833 Japan Phone 81 75 958 1298...