English

16

TESTING AND COMMISSIONING

––– STEP 9 –––

Maintenance must be performed in strict observance of the safety

provisions in this manual and according to current legislation and

standards.

The automation devices do not require special maintenance. However a

check should be performed at least every six months to ensure complete

efficiency of all devices.

For this purpose, the tests and checks envisaged in paragraph 8.1 “Test

-

ing” should all be performed, as well as all procedure in the paragraph

“Maintenance operations permitted for the user”.

If other devices are present, follow the instructions in the relative mainte

-

nance schedule.

MAINTENANCE

devices used (use appendix 1).

02.

Affix a dataplate on the door, specifying at least the following data:

type of automation, name and address of manufacturer (responsible

for commissioning), serial number, year of construction and CE mark.

03.

Permanently attach to the gate the label supplied in the pack, regard

-

ing the procedure for manual locking/release of the gearmotor.

04.

Compile and provide the automation owner with the declaration of

conformity (use appendix 2).

05.

Prepare and provide the automation owner with the User’s guide; for

this purpose appendix “User’s guide” may be used as an example

(chapter 11.3).

06.

Prepare and provide the owner with the form “Maintenance sched

-

ule”, containing all maintenance instructions for all devices in the

automation.

07.

Before commissioning the automation, ensure that the owner is ade

-

quately informed of all associated risks and hazards.

This product is an integral part of the automation and therefore

must be disposed together with the latter.

As in installation, also at the end of product lifetime, the disassembly and

scrapping operations must be performed by qualified personnel.

This product is made of various types of material, some of which can be

recycled while others must be scrapped. Seek information on the recy

-

cling and disposal systems envisaged by the local regulations in your area

for this product category.

Caution!

– Some parts of the product may contain pollutant or hazard

-

ous substances which, if disposed of into the environment, may cause

serious damage to the environment or physical health.

As indicated by the symbol alongside, disposal of this

product in domestic waste is strictly prohibited. Separate

the waste into categories for disposal, according to the

methods envisaged by current legislation in your area, or

return the product to the retailer when purchasing a new

version.

Caution!

– Local legislation may envisage serious fines in the event of

abusive disposal of this product.

PRODUCT DISPOSAL

––– STEP 8 –––

These are the most important phases when setting up an automation, in

order to guarantee maximum safety.

Testing can also be used as a periodic check of devices in the automa

-

tion.

Testing of the entire system must be performed by skilled and

qualified personnel, who are responsible for the tests required to

verify the solutions adopted according to the risks present, and for

ensuring observance of all legal provisions, standards and regula

-

tions, with particular reference to all requirements of the standard

EN 12445 which establishes the test methods for testing automa

-

tions for power-operated gates.

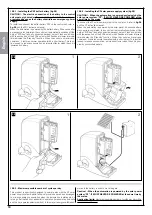

8.1 - TESTING

01.

Ensure that all instructions and warnings in STEP 1 have been

strictly observed.

02.

Using the selector or radio transmitter, test gate opening and closing

and ensure that leaf movement corresponds to the envisaged com

-

mands. Test several times to assess smooth operation of the gate

and check for any defects in assembly or adjustment and any pos

-

sible points of friction.

03.

Check operation of all system safety devices one at a time (photo

-

cells, sensitive edges, etc.). In particular, each time a device trips,

the “ECSBus” led on the control unit emits a longer flash to confirm

control unit recognition of the event.

04.

To test photocells and in particular that there is no interference with

other devices, pass a cylinder (

Fig. 36

) (diameter 5 cm, length 30

cm) through the optic axis, first close to the TX and then the RX and

then mid-way between the two. Ensure that in all cases the device

engages, changing from the active status to alarm status and vice

versa; then ensure that the action envisaged is performed on the

control unit: during closure inverts movement.

05.

Measure the force as specified in the standard EN 12445. If the motor

force control is used as an auxiliary function for reduction of impact

force, test and identify the setting that obtains the best results.

8.2 - COMMISSIONING

Commissioning can only be performed after positive results of all

test phases. Partial or “makeshift” commissioning is strictly pro

-

hibited.

01.

Produce the technical documentation of the automation, which must

include at least the following documents: overall layout drawing (e.g.

fig. 3

), electrical wiring diagram (e.g.

fig. 26

), risk assessment and

solutions adopted, manufacturer’s declaration of conformity for all

36

Summary of Contents for MhouseKit SL10S

Page 2: ......

Page 7: ...Fran ais 7 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 9: ...Fran ais 9 5 7 8 9 10 0 50 moteur fix gauche moteur fix droite 6 36 50 0 50 50...

Page 10: ...Fran ais 10 11 12 14 13 170 170 1 200 200...

Page 11: ...Fran ais 60 11 16 18 19 17 10 0 50 0 50 10 moteur fix gauche moteur fix droite 15 A...

Page 13: ...Fran ais 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 20 B C A 13 5 D E F 6...

Page 14: ...Fran ais 14 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4...

Page 15: ...Fran ais 15 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B...

Page 17: ...Fran ais 17 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4...

Page 34: ......

Page 39: ...English 5 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 41: ...English 7 5 7 8 9 10 0 50 motor fixed on left motor fixed on right 6 36 50 0 50 50...

Page 42: ...English 8 11 12 14 13 170 170 1 200 200...

Page 43: ...English 9 18 19 60 17 10 0 50 0 50 10 motor fixed on left motor fixed on right 15 A 16...

Page 45: ...English 11 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 5 20 6 B C A D E F...

Page 46: ...English 12 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4...

Page 47: ...English 13 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B...

Page 49: ...English 15 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4...

Page 66: ......

Page 71: ...Italiano 5 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 73: ...Italiano 7 5 7 8 9 10 0 50 motore fissato a sinistra motore fissato a destra 6 36 50 0 50 50...

Page 74: ...Italiano 8 11 12 14 13 170 170 1 200 200...

Page 77: ...Italiano 11 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 20 B C A 5 D E F 6...

Page 78: ...Italiano 12 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4...

Page 79: ...Italiano 13 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B...

Page 81: ...Italiano 15 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4...

Page 98: ......

Page 103: ...5 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 106: ...8 11 12 14 13 170 170 1 200 200 Polski...

Page 109: ...11 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 20 B C A 5 D E F 6 Polski...

Page 110: ...12 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4 Polski...

Page 111: ...13 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B Polski...

Page 113: ...15 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4 Polski...

Page 130: ......

Page 131: ......