English

3

Ambient temperature over 40°C or lower than 0°C or humidity

greater than 80%

Solid leaf

Installation in windy zone

Note - The data are based on a sliding gate balanced and in perfect condition maintenance

TABLE A

Severity index

SL1SC SL10SC

< 3 m

3 - 4 m

4 - 5 m

5 - 6 m

6 - 7 m

< 200 kg

200 - 300 kg

300 - 400 kg

400 - 550 kg

Leaf length

Leaf weight

0%

10%

20%

-

-

10%

20%

30%

-

20%

15%

15%

0%

5%

10%

15%

20%

0%

10%

20%

30%

20%

15%

15%

• Make sure that the area where the gearmotor is fixed is not subject to

flooding. If necessary, mount the gearmotor raised from the ground.

• Ensure that the selected surfaces for installation of the various devices

are solid and guarantee a stable fixture; as regards photocells, select a

flat surface that guarantees correct alignment between photocells (Tx

and Rx).

• Ensure that all devices to be installed are in a sheltered location and

protected against the risk of accidental impact.

3.2 - PRODUCT APPLICATION LIMIT

Before proceeding with installation, perform the following checks in the

specified sequence and ensure conformity both with the data in this para

-

graph and the technical data provided in the chapter “Technical Specifica

-

tions”:

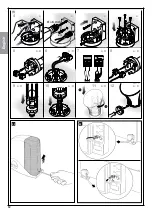

01.

Ensure that the dimensions and weight of the gate are within the fol

-

lowing limits of use:

SL1SC -

maximum length 5 m

-

maximum weight 400 kg

SL10SC - maximum length 7 m

- maximum weight 550 kg

02.

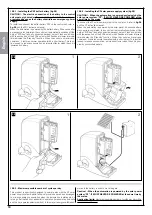

Check the overall dimensions of the gearmotor (

fig. 2

).

Note – These

measurements also serve as a reference to calculate the space

occupied by the foundation pit for routing the electrical cable ducting.

03.

Ensure that the estimated lifetime is compatible with the intended use

(see paragraph 3.3).

04.

Ensure that all limits, conditions and warnings in this manual can be

observed.

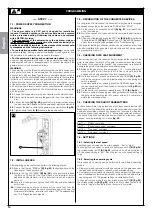

3.3 - PRODUCT DURABILITY

The lifetime is the average economic duration of the product. The value of

lifetime is strongly influenced by the intensity of the manoeuvres, i.e. the

sum of all factors that contribute to product wear, see Table 1. To estimate

the durability of your automation, proceed as follows:

01.

Add up all the values in the items of

Table A

;

02.

In

Graph 1

from the value obtained above, trace vertical line until

it intersects the curve; from this point trace a horizontal line until it

intersects the line of the “manoeuvre cycles”. The value obtained is

the estimated lifetime of your product.

The lifetime values specified in the graph are only obtainable if the mainte

-

nance schedule is strictly observed (see chapter 9 - Maintenance sched

-

ule). The estimation of lifetime is made on the basis of design calculations

and the results of tests performed on prototypes. As it is only an estima

-

tion, it does not represent any form of guarantee on the effective lifetime

of the product.

Example of calculating lifetime: automation of a gate with a leaf length of

3.5 m with weight of 250 kg, for example, in a location near the sea. Table

1 states the “severity index” values for this type of installation: 10% (“Leaf

length”), 20% (“Leaf weight”) and 15% (“Presence of dust, sand or brine”).

These values must be added up to obtain the overall severity index, which

in this case is 45%.

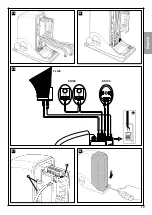

commands sent by the user via a transmitter. It can memorise up to 256

GTX4 transmitters (if memorised in “Mode I”) and up to 6 pairs of PH100

photocells.

Connection of the control unit with the various devices is by means of

a single 2-wire cable (“ECSbus” system). The control unit can also be

mains-powered (230 V) or alternatively by the Mhouse PF photovoltaic

system.

If mains-powered, it can house a buffer battery (mod. PR1, optional

accessory) which guarantees a number of manoeuvres, during the hours

following a mains power failure). During the power failure, or at any other

time, the gate leaf can be moved manually if required, by first releasing the

gearmotor using the relative key (see chapter 11.3 - User’s Guide).

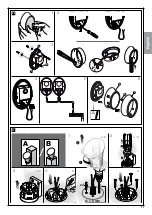

2.2 - COMPONENTS USED TO SET UP A COMPLETE

SYSTEM

Fig. 1

illustrates all components used to set up a complete system, such

as that shown in

fig. 3

.

Components shown in fig. 1:

A

- 1 electromechanical gearmotor SL1SC/SL10SC with integrated con

-

trol unit and foundation plate

B

- 2 limiter brackets

C

- 3 release keys

D

- 1 pair of PH100 photocells (one TX and one RX)

E

- 2 GTX4 radio transmitters

F

- 1 FL100 flashing light with integrated aerial

G

-

Metal hardware

Notes:

- Some devices and accessories specified in the manual are optional and

may not be present in the kit. For a complete description, refer to the

Mhouse product catalogue or visit the website www.niceforyou.com

- The mechanical limit stops are not supplied in the pack and are not part

of the Mhouse product range.

––– STEP 3 –––

PRELIMINARY CHECKS FOR INSTALLATION

3.1 - CHECKING SUITABILITY OF GATE TO BE AUTOMAT-

ED AND RELATIVE ENVIRONMENT

• Ensure that the mechanical structure of the gate complies with current

national standards and that it is suitable for automation. For this check,

refer to the information specified on the gate dataplate.

Important -

This product cannot be used to automate a gate that is not already effi

-

cient and safe; furthermore it cannot solve defects caused by incorrect

gate installation or poor maintenance.

• Manually move the gate in both directions (opening/closing) and ensure

that friction is constant throughout travel (there must be no points of

increased or decreased force).

• If the leaf is fitted in a pedestrian pass door or a door onto the leaf

movement area, ensure that this door does not obstruct normal travel,

and install a suitable interlock device if necessary.

• Manually move the gate to any position; leave it stationary and ensure

that it does not move when left.

• Ensure that there is no risk of gate derailing or risks of exit from the

tracks.

• Ensure that the space around the site of gearmotor installation enables

safe and easy manual gate release.

Summary of Contents for MhouseKit SL10S

Page 2: ......

Page 7: ...Fran ais 7 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 9: ...Fran ais 9 5 7 8 9 10 0 50 moteur fix gauche moteur fix droite 6 36 50 0 50 50...

Page 10: ...Fran ais 10 11 12 14 13 170 170 1 200 200...

Page 11: ...Fran ais 60 11 16 18 19 17 10 0 50 0 50 10 moteur fix gauche moteur fix droite 15 A...

Page 13: ...Fran ais 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 20 B C A 13 5 D E F 6...

Page 14: ...Fran ais 14 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4...

Page 15: ...Fran ais 15 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B...

Page 17: ...Fran ais 17 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4...

Page 34: ......

Page 39: ...English 5 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 41: ...English 7 5 7 8 9 10 0 50 motor fixed on left motor fixed on right 6 36 50 0 50 50...

Page 42: ...English 8 11 12 14 13 170 170 1 200 200...

Page 43: ...English 9 18 19 60 17 10 0 50 0 50 10 motor fixed on left motor fixed on right 15 A 16...

Page 45: ...English 11 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 5 20 6 B C A D E F...

Page 46: ...English 12 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4...

Page 47: ...English 13 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B...

Page 49: ...English 15 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4...

Page 66: ......

Page 71: ...Italiano 5 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 73: ...Italiano 7 5 7 8 9 10 0 50 motore fissato a sinistra motore fissato a destra 6 36 50 0 50 50...

Page 74: ...Italiano 8 11 12 14 13 170 170 1 200 200...

Page 77: ...Italiano 11 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 20 B C A 5 D E F 6...

Page 78: ...Italiano 12 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4...

Page 79: ...Italiano 13 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B...

Page 81: ...Italiano 15 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4...

Page 98: ......

Page 103: ...5 2 300 163 295 84 4 E D A F D B D C D 3 i d e g h a d b b c f l 1 A C D E F B G...

Page 106: ...8 11 12 14 13 170 170 1 200 200 Polski...

Page 109: ...11 21 A B 6 mm x4 A B A B A B B B B 1 2 3 4 1 2 3 4 20 B C A 5 D E F 6 Polski...

Page 110: ...12 22 23 21 A B A B A B A B A B A B 5 6 7 8 9 11 12 10 A B A B 6 mm x4 A A A A 4 Polski...

Page 111: ...13 24 25 TX RX 26 FL100 PH100 KS100 A 28 27 A B Polski...

Page 113: ...15 31 B A C 34 32 A A B 35 A B 30 A B 33 T1 T2 T3 T4 Polski...

Page 130: ......

Page 131: ......