English –

3

EN

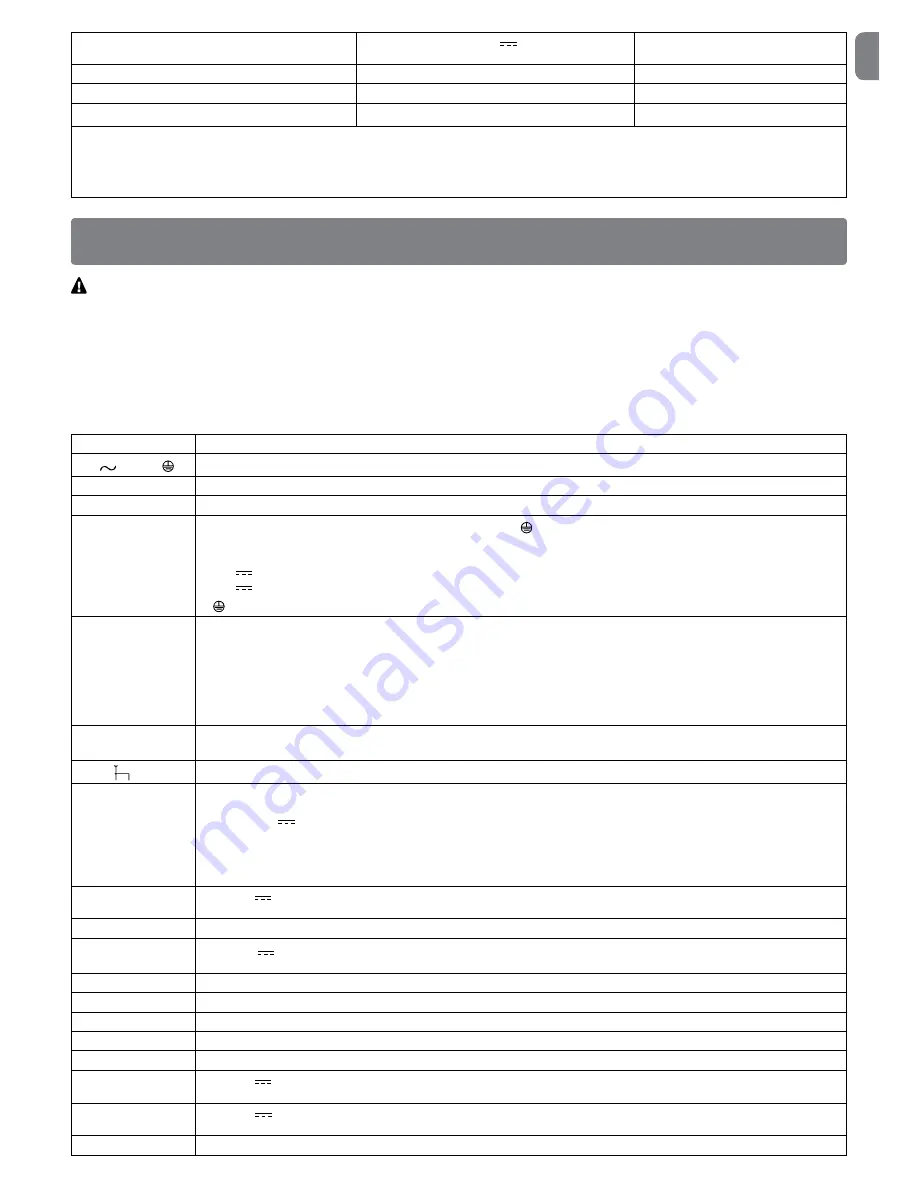

D

: FLASHER cable with aerial

2 x 0.5 mm

2

(for flasher 24V

)

RG58-type screened cable (for aerial)

20 m

10 m (5 m recommended)

E

: PHOTOCELL cable

4 x 0.5 mm

2

20 m

F

: KEY SWITCH cable

2 x 0.25 mm

2

cables

20 m

G

: COILED cable for sensitive edge

Note 1

– If the power cable exceeds 30 m in length, a cable with a larger section (3 x 2.5 mm

2

) must be used and safety grounding near the automation must

be installed.

Note 2

– These 2 cables can be replaced with just one 4 x 0.5 mm

2

cable

CAUTION! – The cables used must be suitable to the type of room where the unit is installed.

3

ELECTRICAL CONNECTIONS

CAUTION!

– Before you proceed to make any electrical connections make sure that the power supply is disconnected;

– Connections must only be carried out by qualified personnel.

– You must put a device on the electricity supply line that ensures complete disconnection of the automated mechanism from the mains supply. The discon-

nection device must have contacts with an opening distance large enough to permit complete disconnection under the conditions sanctioned by overvoltage

category III, in accordance with installation regulations. The device ensures quick, safe disconnection from the power supply if needed, and must therefore

be in a position that is visible from the automation mechanism. If, on the other hand, it is located in a position which is not visible, there must be a system for

preventing accidental or unauthorised reconnection to the mains supply to prevent this risk. The disconnection device is not supplied with the product.

3.1 - Connection description

Find below the description of the meaning of the marks printed on the electronic board at the relative terminals:

PUSH BUTTONS

Input for the connections of the buttons on the box lid

24V

Ground

Input for the connection of the transformer power

Battery (symbol)

Connector for the connection of the buffer battery mod. PS224

Incremental encoder

Terminal for the connection of the encoder of the Sumo- family motors - No polarity to comply with

Motor

Terminal for the connection of the electrical motor and the ground

Attention to polarity

: connect the motor so that, when the opening command is given, the opening of the door matches it on the

control unit

1

: 24V

motor

2

: 24V

motor

3

:

motor

Limit Switch

(function unavailable)

Connector for the electromechanical limit switch connection:

Common

: limit switch common

Open

: input of maximum opening limit switch

Preclose

: input of the preclosing limit switch, adjusted at about 3 cm above the closing limit switch. The detection of obstacles, or

sensitive edge, between the closing and pre-closing position, stops the closing movement and the control unit considers the door in

completely-closed position.

Open

: input of maximum closing limit switch

IBT4N

Input for the connection of the Oview programmer, with the appropriate IBT4N adapter.

CAUTION! - Disconnect the power before connecting/disconnecting the programmer.

Aerial

Input for the connection of the radio receiver aerial (note: in Nice flashers Mod. ELDC, the aerial is built-in)

STOP

Input for the connection of resistive-type sensitive edges (8k2) or optical ones (OSE), as described below (

fig. 5

):

OSE connection

:

- positive 12V

(+) (brown wires)

- signal (S) (green wires)

- negative GND (-) (white wires)

Connection 8k2

:

- Connect the 8.2 kΩ resistance between the Signal and GND terminals

Common

24V output

(-30%; +50%) acting as common for the SbS input; when the control unit is in Standby mode (low consumption), this

output is not off.

Sbs

Input for a NO (normally open) button to send commands in Step-by-Step mode; input reconfigurable using the Oview programmer.

COM SBY

24V output

(-30%; +50%) acting as common for the Open, Close, Photo and Photo2 inputs; when the control unit is in Stand by

mode (low consumption) this output is off

Open

Input for a NO (normally open) button to send commands in Open mode; input reconfigurable using the Oview programmer.

Close

Input for a NO (normally open) button to send commands in Close mode; input reconfigurable using the Oview programmer.

Photo

Input for Photocell-type safety devices with NC (normally closed) contact; the intervention takes place during the closing manoeuvre.

Photo2

Input for Photocell-type safety devices with NC (normally closed) contact; the intervention takes place during the closing manoeuvre.

GND

Negative GND

24V

24V output

(-30%; +50%) 200mA to power services; when the control unit is in Standby mode (low consumption), this output is

not off.

Phototest

24V output

(-30%; +50%) 200mA to power photocells in phototest mode; when the control unit is in Standby mode (low con-

sumption), this output is not off.

Out1 (Flash)

Output for flasher at 24V 25W with self-flashing (ELDC)