English –

7

EN

‘hold-to-run’ mode, until synchronization of the encoder position is completed.

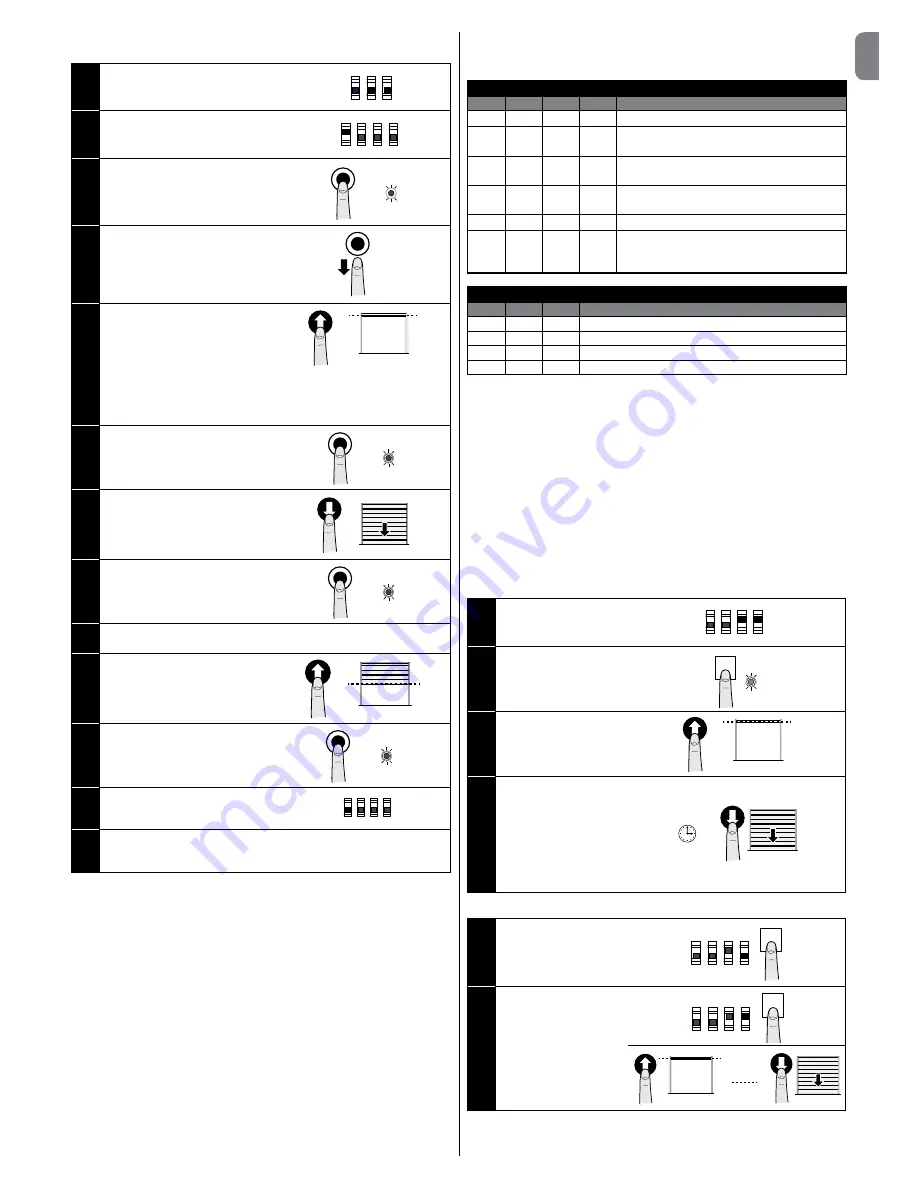

To perform this procedure, follow the following instructions:

01.

Select the type of motor, setting

dip switches B-2 and B-3 to OFF

OFF

1

2

3

B

02.

Set dip switch A-1 to ON (A-2,

A-3 and A-4 are OFF)

OFF

1

2

3

4

ON

A

03.

Keep the STOP button pressed

until the led is on with fixed red

light (after about 3 seconds)

3”

04.

Release the STOP button

05.

Press the OPEN button to bring

the door to the desired open po-

sition

Caution!

- if the sense of rotation does not match the set direction (OPEN button =

opening direction, it is necessary to swap the positive and negative poles

of the motor cables and repeat the learning procedures from the start

06.

Keep the STOP button pressed

for 3 seconds until the led flashes

once with red light

3”

x 1

07.

Press the CLOSE button to bring

the door to the maximum closing

position

08.

Keep the STOP button pressed

for 3 seconds until the led flashes

twice with red light

3”

x 2

09.

If you do not wish to set the “partial opening” value, set dip switch A-1

or B-1 to OFF and go to step 12 of this procedure

10.

Press the OPEN button to bring

the door to the desired partial

opening position (e.g. half stroke)

11.

Keep the STOP button pressed

for 3 seconds until the led flashes

three times with red light

3”

x 3

12.

Set dip switch A-1 to OFF

ON

OFF

1

2

3

4

A

13.

Set dip switches A-3 and A-4 as per Table 3 for the desired operating

mode and confirm the setting of the dip switch with the P1 button on

the control unit

CAUTION! – The recognition phases must not be interrupted. If there is

an interruption, you must repeat the entire recognition process.

Once the position learning phase has been completed, it is necessary

to carry out learning about the handling forces: carry out 4 complete

manoeuvres; if the manoeuvre is not completed (e.g. for amp meter

intervention or stop or photo intervention) it is not counted. Until this

phase is complete, the OK led is flashing with red and green light during

the manoeuvre, THAT IS CARRIED OUT AT MAXIMUM FORCE.

Note: if the speed or slow down positions are modified or if the

sensitivity is activated, the force learning phase must be repeated.

4.5 - Operating modes

CAUTION! - If the functions of Table 3 are programmed with the Oview

programming unit, it is necessary to set the dip switches to OFF.

TABLE 3: DIP SWITCH A

DIP1 DIP2 DIP3 DIP4 Function

OFF

OFF

OFF

OFF

Hold-to-run movement

ON

X

OFF

OFF

Acquisition of positions and status of the ALT

input

OFF

ON

OFF

OFF

Rotation direction of the encoder reversed

(only for absolute encoder)

OFF

X

OFF

ON

Industrial mode (semi-automatic opening –

hold-to-run closing), if positions recognised

OFF

X

ON

OFF

Semi-automatic mode, if positions recognised

OFF

X

ON

ON

Automatic mode with adjustable pause time,

if positions recognised (see para. 4.5.1 “Set-

ting the automatic closing pause time”)

TABLE 4: DIP SWITCH B

DIP1 DIP2 DIP3 Function

OFF

X

Sensitivity disabled

ON

X

Sensitivity enabled

*

X

X

OFF

Motor with encoder

X

X

ON

Motor with electromechanical limit switch

*

Note: the sensitivity parameter allows reducing the door strength of interven-

tion against an obstacle considerably.

During the “Learning about the safety devices” procedure, the control

unit stores the status of dip switches A and B. At the end of this proce-

dure, a variation in the dip switches causes the OK led to flash quickly

with red and green light alternately to highlight the change in configura-

tion; in this phase the control unit allows no commands to be executed.

It is necessary to carry out a new “Learning about the safety devices”

procedure (paragraph 4.3) or press the P1 button for 2 seconds.

Once the positions have been acquired, it is necessary to perform 4

complete manoeuvres to get the control unit to store the force required

to move the door; the manoeuvres are represented by the OK led flash-

ing slowly with red and green light alternately.

The “force and sensitivity” parameters can be adjusted with the Oview pro-

grammer (accessory).

4.5.1 - Setting the automatic closing pause time

01.

Set dip switches A-3

and A-4 to ON

ON

OFF

1

2

3

4

A

02.

Press the P1 button for

2 seconds (the OK led

flashes with green light)

P1

OK

2”

03.

Send an opening com-

mand to bring the door

to the maximum open-

ing position

04.

Once this position is

reached, wait for a time

equal to the desired

automatic closing pause

time and send a closing

command.

The automatic closing

pause time is now

stored

4.5.2 - Modifying the pause time value

01.

Set dip switch A-4 to

OFF and confirm with

the P1 button for 2

seconds

ON

OFF

1

2

3

4

A

P1

2”

02.

Set dip switch A-4 to

ON and confirm with the

P1 button for 2 seconds

At this point the open-

ing, pause time and

closing sequence must

be repeated.

ON

OFF

1

2

3

4

A

P1

2”

CAUTION! - When dip switch A-4 is set to OFF, the pause time is can-

celled.