4VAL Operating & Maintenance Manual Version 1.1 © Newman Labelling Systems Ltd Page 12 of 56

Documented training with certificates for all attendees along with course

documentation is increasingly being requested and Newman is able to quote and

provide this service. Please contact Newman for further information.

2.3 INSTALLATION

Prior to starting Installation it is important to fully understand the following

instructions. Unpack the machine very carefully to avoid damage and make sure that

all small items and boxes are retained before discarding the packaging. Screw in the

four adjustable feet (or castors), move the machine into position, set the conveyor

height and level machine by adjusting the feet.

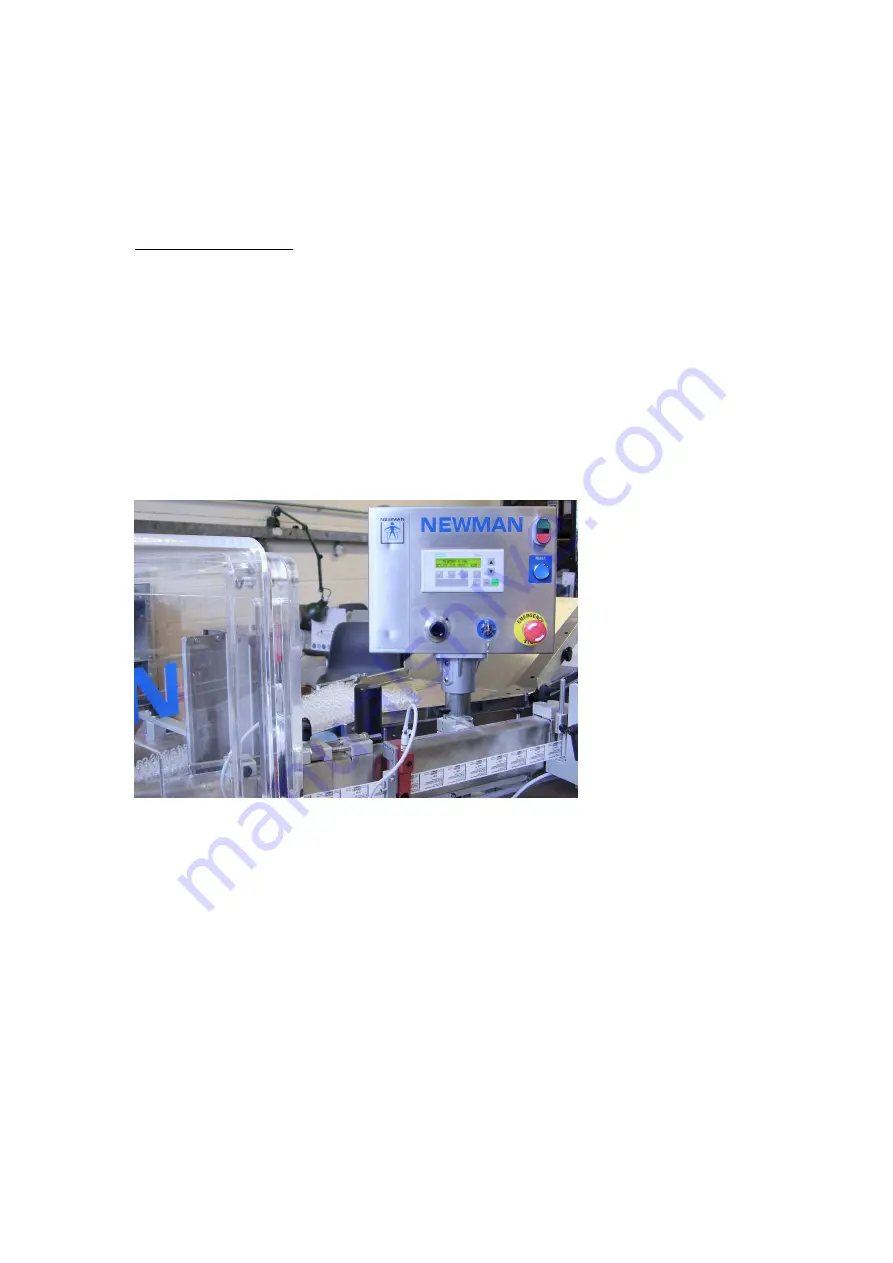

The Operator Panel has been lowered to approximately guard level for transport

purposes as shown in photo below. This needs to be raised to a suitable height for

operation. Ensure that one person supports the box before another person releases the

clamp to raise the box.

Operator panel lowered for shipment

Reassemble the coder (if fitted) to the machine and connect the pneumatic and

electrical services. The coder is usually secured onto the label arm mounting bracket

with 4 off M6 socket head screws.

Check that your electrical supply details correspond with those on the machine plate

and machine electrical drawings. Ensure that a suitably qualified person connects the

supply to the isolator. If your supply uses an earth leakage circuit breaker (ELCB) /

residual current device (RCD) it is recommended to be 100mA minimum trip rating.

The machine is supplied with all guards necessary for safe operation. If any

modifications are made for any reason, care should be taken to ensure that the overall

safety is not impaired.