20

MaxiMailer HD Operator Manual

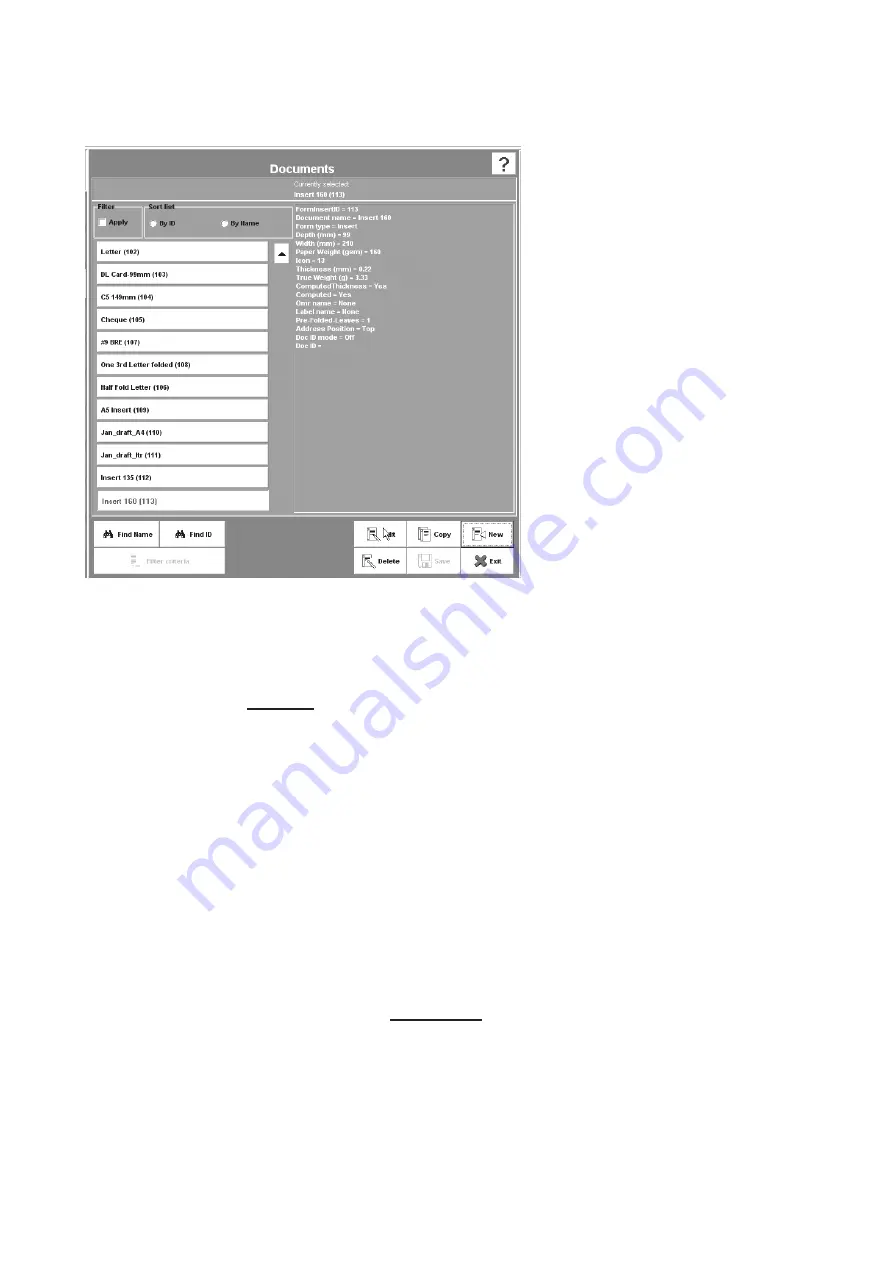

Press any of the buttons on

the Setup screen to display a

list box. Shown left is the list

box for the Document, and is

similar for all of the buttons

on the Setup screen. The list

box shows all of the setups

that have been defined so far.

Select any of the setups shown

and this can then be edited,

copied or deleted by clicking on

the appropriate button at the

bottom of the box. New setups

can also be created by pressing

on the

new

button, and the

newly created item can then be

edited as required. Note that

each name is allocated an ID

number by the software, this

being appended to the name.

You can sort the list by ID or

name, and if the list is long and

a scroll bar appears, you can

also search the list by name

or ID using the buttons at the

bottom. A filter can also be applied, to list only names or IDs containing criteria, such as a

keyword or a part of it.

When either the

new

or

edit

buttons are clicked, the edit screen for that particular setup is

displayed. These are explained in detail on the page indicated below:

list box

OMR Code:

Page 21

barcode/labels:

Page 23

Documents:

Page 25

envelopes:

Page 27

Configuration:

Page 29

Job:

Page 38

Users:

Page 39

If any changes are made to the list box (ie. if an existing item is copied or deleted), the

save

button will be active. Press this to save the changes, and click

exit

. Note that if an

item is edited, changes will be saved on that particular edit screen, and the

save

button will

remain dimmed.

Warning!!

for the ‘OMR Code’, ‘bar Code’, ‘Documents’ and ‘envelopes’ list boxes, do

not

delete a setup that is currently used in any configuration. If you do, the

configuration that uses the setup will be substituted with the factory configuration

named ‘Default Config’, which cannot be deleted or edited (for further details of

Configurations, see page 29).

5.4.2 The list box