SECTION 3

OPERATING THE PRINTER

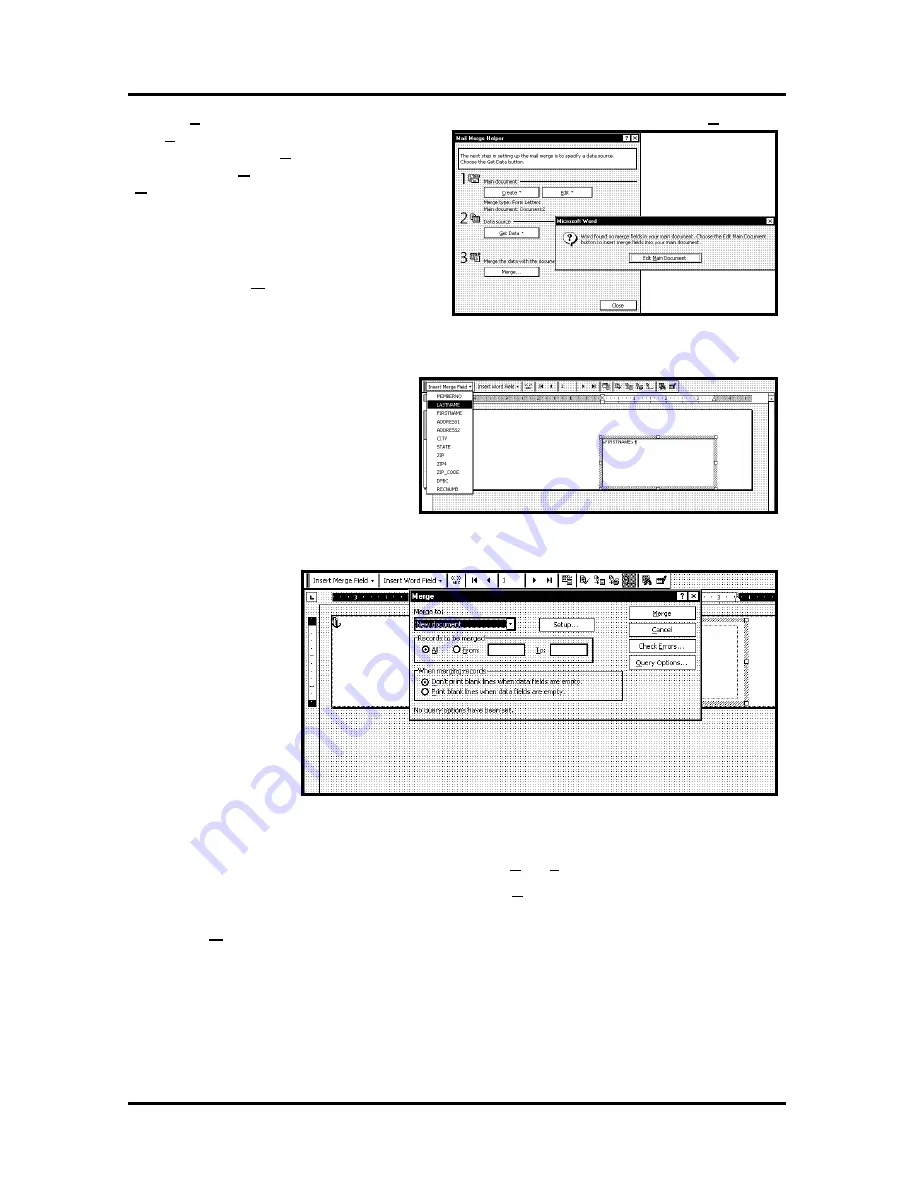

Click on

Tools

and then

Mail Merge

. The “Mail Merge Helper” window will open. Click On

Create

,

then

Envelopes

. The “Microsoft Word” window

will open. Click on the

Active Window

button,

then click on the

Get Data

button. Next click on

Open data

source. Locate the data file you intend

to use. In our example we are using a Microsoft

Excel file. Select the file and the “Microsoft

Excel” window opens select entire spreadsheet

and click

OK

.

Next click on

Edit Main Document

and then

click on

Close

.

Use the Mail Merge Tool Bar and click on

Insert Merge Field and begin to build the

layout by inserting the address fields.

When you have

completed setting up the

layout, click on the

Merge

icon on the tool

bar and the “Merge”

window will open.

In the

Merge to

menu

there are several choices

for where how the data is

exported. The two that

concerns us is “New

Document” and

“Printer”. If you choose

“New Document” the

merge will be created in your word application with a separate record for each address. If you choose

“Printer”, the merge will send directly to the printer and each record will be printed.

The next selection is “Records to be merged”. You can select

All

or

From

:.

The last selection is “When merging records”. The default is “Don’t print blank lines when data fields are

empty.” This should be left checked.

Clicking on

Merg

e will start the process of merging the documents.

If you chose to send the merge directly to the printer and the printer is connected to the computer and

turned ON, the printer will start. Pressing the

ENTER

key will start the printing process.

If you have a graphic or fixed text to be printed with the data, refer to the section on Overlays.

© 2009 Neopost USA Inc. All rights reserved.

35

Summary of Contents for AS-940

Page 1: ...AS 940 Addressing Solution Operating Guide...

Page 12: ...SECTION 1 GETTING ACQUAINTED Notes 2009 Neopost USA Inc All rights reserved 12...

Page 36: ...SECTION 3 OPERATING THE PRINTER Notes 2009 Neopost USA Inc All rights reserved 36...

Page 42: ...Notes 2009 Neopost USA Inc All rights reserved 42...