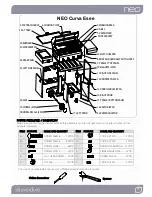

4

APPLIANCE DETAILS

Gas Type:

Universal LPG

(Propane and/or Butane gas)

N.G.

Burner Pressure:

2.75 kPa

0.95 kPa

Injector Diameter:

Ø1.10 mm

Ø1.65 mm

Heat Input:

60 MJ/ hr

50 MJ/ hr

Wok Injector Diameter:

Ø0.90 mm

Ø1.65 mm

Wok Heat Input:

10.5MJ/hr 12.5MJ/hr

Note:

The size of the injector diameter is stamped on one of the hexagon faces (e.g. ‘104’ for Ø1.04mm injector).

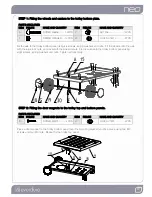

Air is admitted at the underside of the front and rear of the combustion chamber. Exhaust gases are emitted

through the grill plate, around the edge of the hot plate and through the louvers in the rear of the hood.

The Esee lighting system requires a 240Vac supply (via a standard Australian socket outlet). The supplied power

pack is rated to IP64, and supplies 12Vac with a maximum output of 20VA. This transformer complies to

Australian Standards AS/NZS 3108 (Safety) and AS/NZS 1044 (EMC).

GAS CONNECTIONS

LOCAL AUTHORITY REQUIREMENTS

Check Gas Type and specifications plate on the left-hand side of the barbecue. All gas fitting work, service and repairs

can only be performed by an authorised person in accordance with AS5601 / AG601 and local gas regulations.

NATURAL GAS

Neo 4 burner barbecues can be converted to use natural gas ONLY with a Neo NG 4 burner conversion kit. Fit the NG

cross-over adaptor, NG manifolds, regulator and NG hose. This conversion can ONLY be performed by an authorised

person in accordance with AS5601 / AG601 and local gas regulations.

Note: The burner pressure (as noted on the appliance details) MUST be checked after installation by turning on and

measuring at the regulator output test point. All connections must be checked for leaks.

FOR GAS CYLINDER CONNECTION

1.

To achieve the optimum performance from your Barbecue, an approved gas cylinder (POL fitting) of 9kg capacity

must be used.

2.

Do not connect gas to a barbecue that is not secured in a trolley.

3.

Connect the cylinder to the barbecue, via the hose and regulator. Firmly tighten joints, but do not over-tighten. Take

care not to damage the regulator fitting.

LEAK TESTING

1.

Make sure gas controls are Off and turn the cylinder valve On.

2.

Check for leaking joints by brushing with solution of half-liquid detergent and half water. If a leak is present, bubbles

will appear (or you will hear a hissing sound). Retightening connections can generally repair a leaking joint. You must

also check the gas hose and connection at the gas cylinder, and at the wok burner. If a leak cannot be resolved, do

not proceed.

LEAK TEST ALL CONNECTIONS, INCLUDING THE CONNECTION

TO THE GAS CYLINDER.

DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.

IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.

LENGTH (mm)

WIDTH (mm)

HEIGHT (mm)

Barbecue only 830

545

220

Argento Esee & Figura Esee

1540

640

1220

Barbecue

and Trolley

Curva Esee

1510

640

1220

Secondary Air Inlet (Front)

15mm x full width of fat tray

Secondary Air Inlet (Rear)

54 x Ø22mm holes