NED

UME-0034-03

XCM8060SA_8040SA_6040SA

51

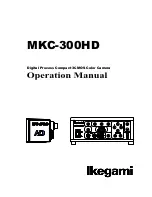

4.13 Test Pattern

This camera can generate a test pattern. Use the test pattern to verify the proper

timing and connections between the camera and the frame grabber board.

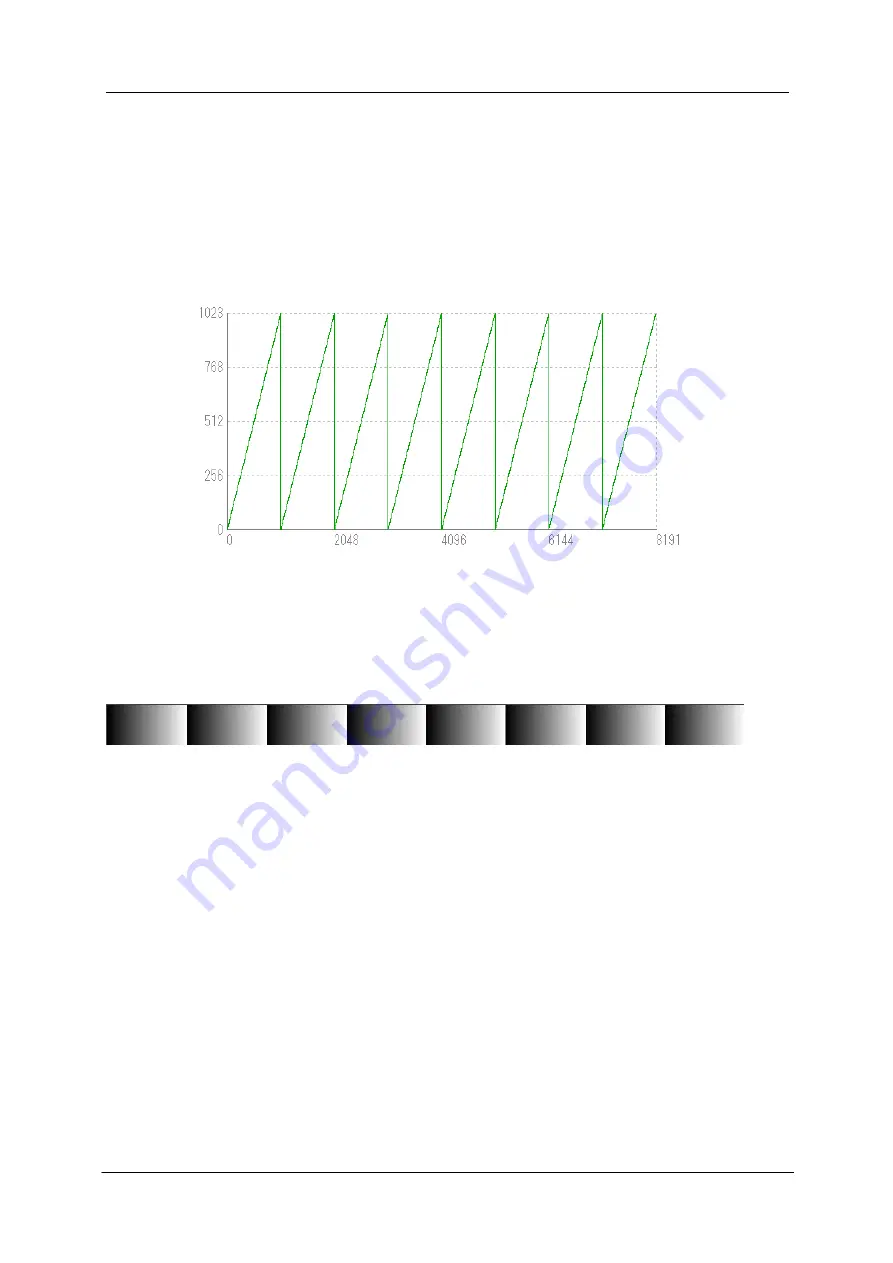

The test pattern of XCM8060SA, XCM8040SA is as follows.

Figure 4-13-1 Test Pattern of XCM8060SA, XCM8040SA

Figure 4-13-2 Test Image of XCM8060SA, XCM8040SA

The test pattern is a ramp from 0 to 1023DN in 10-bit mode, and then starts at 0 again.