AD-25182501

CHAPTER 3

Page 23

Revision 1.0.1

NAP- 200-003

Sheet 5/29

Installation of Main Equipment

(4)

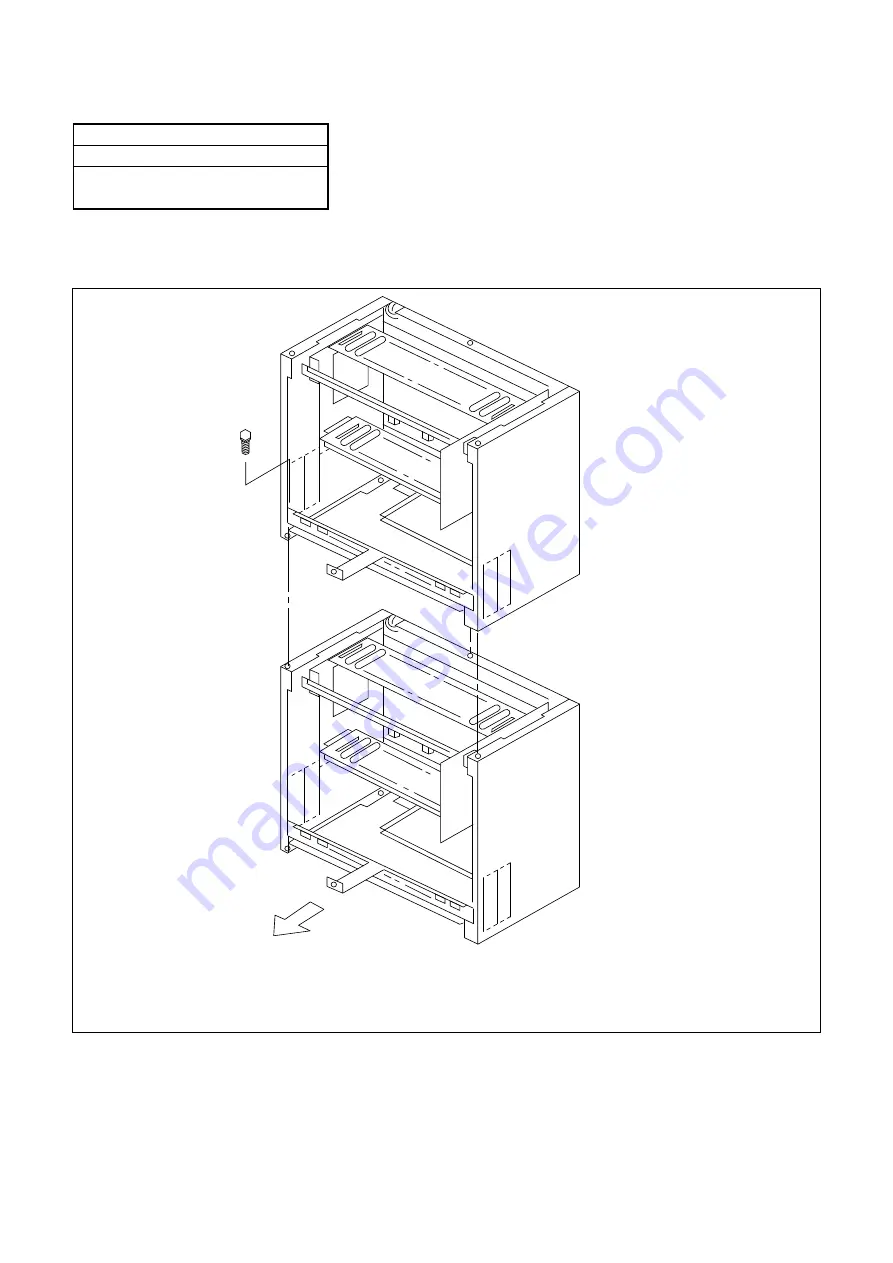

When the system is a multiple-PIM configuration, connect PIMs to each other as shown in Figure 003-5,

using the 3 hex-bolts supplied.

Figure 003-5 Connection of PIMs

Note 1 :

The BATTM and/or the MDFM can be installed the same as the PIM.

Note 2 :

For simplicity, the BASE and RACK PARTS are not shown.

PIM

Note

PIM

Note

FRONT