98 Inspection and Maintenance Schedule

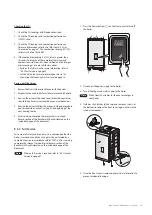

Inspecting the Ignition and Flame Detector Electrodes

1. Remove the ignition and flame detector electrodes from the

boiler heat exchanger.

2. Remove any deposits accumulated on the ignition/flame

detector electrode. If the electrodes cannot be cleaned

satisfactorily, replace with new ones.

3. Replace ignition/flame detector electrode, making sure

gasket is in good condition and correctly positioned.

Checking the Ignition Ground Wiring

1. Check that the ground wire is in good condition and

securely attached to the boiler casing.

2. Check ground continuity of wiring using continuity meter.

3. Replace ground wires if ground continuity is not satisfactory.

Checking all Boiler Wiring

Inspect all boiler wiring, making sure wires are in good condition

and securely attached.

Checking the Control Settings

Check settings of external limit controls (if any) and adjust if

necessary.

Performing Start-up and Checks

1. Start boiler and make sure that the boiler is operating

properly.

2. Verify cold fill pressure is correct and that operating pressure

does not go too high.

Check the Burner Flame

1. Inspect flame through observation window.

2. If the flame is unsatisfactory at either high fire or low fire,

check for obstructions in the flue.

Checking all Piping for Leaks

Eliminate all system or boiler leaks. Continual fresh makeup

water will reduce boiler life. Minerals can build up in sections,

reducing heat transfer, overheating heat exchanger, and causing

heat exchanger failure. Leaking water may also cause severe

property damage.

1. Inspect all water and gas piping and verify to be leak free.

2. Look for signs of leaking lines and correct any problems

found.

Checking the Flue System and Air Piping

1. Visually inspect the entire gas flue system for blockage,

deterioration or leakage. Repair any joints that show signs of

leakage. Verify that air inlet pipe is connected and properly

sealed (if installed).

2. Verify that boiler flue discharge and air intake are clean and

free of obstructions.

WARNING

Failure to inspect for the above conditions and have them

repaired can result in severe personal injury.

Checking the Water System

1. Verify all system components are correctly installed and

operational.

2. Check the cold fill pressure for the system. Verify it is correct

(must be a minimum of 0.8 bar).

3. Watch the system pressure as the boiler heats up (during

testing) to ensure pressure does not rise too high.

Note

●

If the system contains glycol, test for proper

concentration as recommended by manufacturer.

●

Excessive pressure rise indicates expansion tank

sizing or performance problem.

4. Inspect automatic air vents and air separators. Remove air

vent caps and briefly press push valve to flush flue.

5. Replace caps. Make sure flues do not leak. Replace any

leaking flues.

Summary of Contents for NCB300-28K

Page 3: ......

Page 4: ...Revisions 3 Version Description of changes Date 1 00 First issue September 7 2022 Revisions...

Page 106: ...Memo...

Page 107: ...Memo...

Page 108: ...Memo...