• O

rig

inal ope

ra

ting instru

c

tions

•

Saf

e

t

y in

f

o

rma

tion

3. Intended use

T

he pole-mou

nt

ed pet

r

ol-po

w

e

r

ed pruner is

suitable

f

or e

xt

ensi

v

e s

a

wing

w

o

rk

,

f

elling t

r

ees

or s

a

wing a

n

y m

at

e

r

ials other than

w

ood

.

T

he equipme

n

t m

a

y be used only

f

or its i

nt

ended

pu

r

pose.

An

y other use is deemed

t

o be a case

of misuse

.

T

he user/ope

rat

or and not the manufa

c

tu

r

er will

be liable

f

or a

n

y damage or inju

r

ies of a

n

y

k

ind

which

r

esult f

r

om such misuse

.

P

lease no

t

e th

a

t our equipme

n

t has not been

desi

g

ned

f

or use in

c

omme

rcial

, t

r

ade or

indust

r

ial applic

a

tions. Our

warrant

y will be

v

oided if the equipme

n

t is used in

c

omme

rcial

,

tr

ade or indust

r

ial businesses or

f

or equi

v

ale

n

t

pu

r

poses

.

4. Technical data

Engi

ne

t

ype: 2-s

tr

o

k

e en

gin

e

,

ai

r-c

ooled, ch

r

ome

c

ylinder

Eng

ine po

w

er (max.): 0.85 kW/ 1.2 HP

Displa

c

eme

n

t: 32.6 cm

3

Eng

ine idle speed: 3400 min

-1

M

ax. en

g

ine speed: 9500 min

-1

M

ax. cutting length: 254 mm

We

igh

t wit

h

cu

tt

e

r

b

a

r

an

d

chai

n: 7.6

kg

Chain:

K

angxin AL

P

-50-39S

C

ut

t

e

r

ba

r

:

Kangxi

n

A

L10-39-507

P

,10"

Ig

nition: Ele

ctr

onic

Driv

e:

C

e

ntr

ifugal clu

tch

T

ank capac

ity

: 825

ml

Spa

r

k plug: L8

RT

F/NH

S

P LD

Sound and vibration

L

pA

sound p

r

essu

r

e le

v

el: 93,9 dB(

A

)

K

pA

un

c

e

rtainty

: 2,5 dB

L

W

A

sound po

w

e

r

l

e

v

e

l

: 108,2 dB(

A

)

K

W

A

un

c

e

rtainty

: 2,5 dB

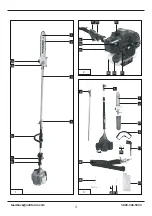

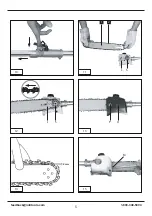

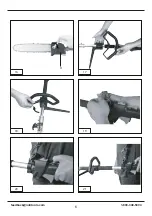

2. Layout and items supplied

2.1 Layout

1.

C

ut

t

er bar

2.

Sa

w chain

3a. Oil tank / cap

3b.

G

ear unit

4. D

riv

e

r

od mechanism

5.

C

onne

c

ting pie

c

e

6.

A

dditional handle

7.

Ey

elet

8. Handle

10.

Thr

ottle lock

11.

Thr

ottle le

v

er

12. Spa

r

k plug boot

13.

Start

er cable

14.

P

et

r

ol tank / cap

16. Choke le

v

er

17. Clip

18.

Scr

ew (4x)

19. Open

-

ended w

r

ench si

z

e 8/10

20.

A

llen key

21.

C

ut

t

er gua

r

d

22.

Carr

ying st

r

ap

23. Oil/pet

r

ol mixing bottle

24.

M

ultifun

c

tion

t

ool

25. Lub

rica

tion nipple

26.

F

uel pump “p

r

ime

r“

2.2 Items supplied

• Open the pac

kag

ing and take out the

equipme

n

t with ca

r

e.

•

R

emo

v

e the pac

kag

ing m

at

e

r

ial and a

ny

pac

kag

ing and/or t

r

anspo

rta

tion b

rac

es (if

av

ailable). • Check

t

o see if all i

t

ems a

r

e p

r

ese

nt

.

•

I

nspe

c

t the equipme

n

t and a

cc

esso

r

ies

f

or

tr

anspo

r

t damage.

•

I

f possible, keep the pac

kag

ing u

n

til the end

of the gua

rant

ee pe

r

iod

.

Important!

The equipment and packaging material are

not toys. Do not let children play with plastic

bags, foils or small parts. There is a danger of

1-800-348-5004

10

Summary of Contents for BlueMAX 53542

Page 4: ...4 5 4 3a 3b 25 4 6 8 5 K I N G R G H 7 9 1 800 348 5004 feedback natitools com 4...

Page 5: ...2 mm 10 12 14 11 13 15 1 2 L S L P S O M 1 800 348 5004 feedback natitools com 5...

Page 6: ...16 18 20 17 19 21 O 1 800 348 5004 feedback natitools com 6...

Page 7: ...23 25 27 24 26 a b T 22 1 800 348 5004 feedback natitools com 7...

Page 8: ...29 28 30 13 1 800 348 5004 feedback natitools com 8...