6.3 Chain lubrication

Important! Never operate the chain if it is not

lubricated with saw chain oil. Use of the chainsaw

without saw chain oil or if the oil level is below

the „min“ mark will damage the chainsaw.

Important!

Be aware of the temperature

conditions:

temperatures.

At lower temperatures you will need

viscosity oil is used during the summer it will

become even thinner due to the ambient

temperatures alone, and as a result the

chain to overheat and become damaged. In

addition, the chain oil would burn and produce

unnecessary pollutants.

Filling the oil tank (Fig. 1):

area around the oil tank cap (Fig. 3a) and then

clean the oil tank cap.

Fill the tank (Item 3a) with saw chain oil. In the

process, make sure that no dirt enters the tank,

as this could cause the oil nozzle to become

blocked. Close the oil tank cap.

7. Operation

Please note that the statutory regulations

location to another.

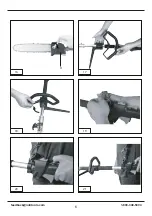

7.1 Starting with a cold engine

Fill the tank with the required amount of oil/

petrol mix. See “Fuel and oil”.

1. Set the equipment down on a hard, level

surface.

2. Press the fuel pump (primer) (Fig. 2/Item 26)

10 times.

4. Set the choke lever (Fig. 2/Item 16) to” “.

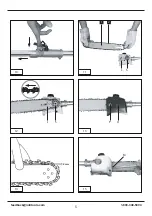

length changes. It is important therefore to check

the chain tension at least every 10 minutes and

to adjust it again as required. This applies in

particular to new saw chains. When you have

will shorten when it cools down. This will help to

prevent damage to the chain.

5.5 Fitting the additional handle

Fit the additional handle as shown in Fig. 17-18.

6. Before starting

Each time before use, check the following:

•

That there are no leaks in the fuel system.

•

That the equipment is in perfect condition and

that the safety devices and cutting devices

are complete.

•

That all screws are securely fastened.

•

That all moving parts move smoothly.

6.1 Fuel and oil

Recommended fuels

Use only a mixture of unleaded petrol and special

2-stroke engine oil. Mix the fuel mixture as

indicated in the fuel mixing table.

Important: Do not use a fuel mixture which has

been stored for longer than 90 days. Important:

Never use 2-stroke oil with a recommended

mixing ratio of 100:1. The manufacturer’s

warranty will be voided in case of engine damage

due to inadequate lubrication. Important: Only

use containers designed and approved for the

purpose to transport and store fuel.

Pour the correct quantities of petrol and 2-stroke

oil into the mixing bottle (see scale printed on

the bottle). Then shake the bottle well.

6.2 Fuel mixing table

Mixing procedure: 40 parts petrol to 1 part oil

Petrol

2-stroke oil

1 liter

25 ml

5 liters

125 ml

1-800-348-5004

12

Summary of Contents for BlueMAX 53542

Page 4: ...4 5 4 3a 3b 25 4 6 8 5 K I N G R G H 7 9 1 800 348 5004 feedback natitools com 4...

Page 5: ...2 mm 10 12 14 11 13 15 1 2 L S L P S O M 1 800 348 5004 feedback natitools com 5...

Page 6: ...16 18 20 17 19 21 O 1 800 348 5004 feedback natitools com 6...

Page 7: ...23 25 27 24 26 a b T 22 1 800 348 5004 feedback natitools com 7...

Page 8: ...29 28 30 13 1 800 348 5004 feedback natitools com 8...