instructions.

• Ne

v

er cut with the upper edge or the tip of the

cutt

er ba

r.

hand

s.

C

utting wood which is under

t

ension

S

pe

ci

a

l c

a

r

e is

r

eq

uir

ed when

cutt

ing w

oo

d wh

ic

h

is under

t

ension.

C

utting wood which is under

t

ension can

r

elease the

t

ension, causing the

wood

to r

ea

c

t out of

control. I

n the worst case

this can

r

esult in se

v

e

r

e and e

v

en fatal inju

r

ie

s.

T

his

t

ype of w

or

k must be pe

r

f

or

med only b

y

specially t

r

ained person

s.

9. Maintenance

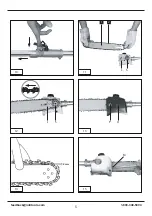

9.1 Replacing the chain and cutter bar

T

he cut

t

er bar needs

t

o be

r

epla

c

ed if • the guide

g

roov

e of the cut

t

er bar is w

orn.

Proc

eed as desc

r

ibed in the se

ction „F

itting the

cutt

er bar and the chain

“.

9.2 Checking the automatic chain lubrication

Y

ou should check the operation of the au

tom

a

tic

chain lub

ric

a

tion syst

em on a

r

egular basis in

or

der

t

o gua

r

d against

ov

e

r

heating and the

damage this can cause

t

o the cut

t

er bar and the

chain.

Poin

t the tip of the cut

t

er bar at a smooth su

r

fa

c

e

(a boa

r

d or a cut t

r

ee fa

c

e) and all

o

w the

chainsaw

to run. I

f

y

ou see a g

ro

wing oil stain

on the smooth su

r

fa

c

e, the au

tom

atic chain

lub

ric

a

tion syst

em is w

ork

ing p

r

ope

rly. I

f

the

r

e is no clear oil stain, please

r

efer

t

o the

corr

esponding instru

c

tions in the se

ction

„Tr

oubleshooting

“. I

f the inf

orm

a

tion

con

tained the

r

e still fails

to r

emedy the

situ

ation, please

con

ta

c

t our se

rvic

e depa

r

tme

nt

I

mpo

r

ta

nt! Do no

t a

c

tua

lly touc

h

t

he su

r

fa

c

e with

the tip of the cut

t

er bar when pe

r

f

or

ming this

t

es

t.

Keep a safe distan

c

e (app

ro

x. 20 cm).

9.3 Sharpening the chain

possible if the chain is in good

c

ondition and

sha

r

p

.

T

his also

r

edu

c

es the

r

isk of

kick

bac

k.

T

he chain can be

r

e-sha

r

pened by a

n

y deale

r. Do

not

a

tt

empt

t

o sha

r

pen the chain

y

ourself unless

y

ou ha

v

e the ne

c

essa

r

y special

t

ools and

expe

r

ien

c

e

.

supplying

t

oo little air

t

o the ca

r

bu

r

e

tor. R

egular

should be checked af

t

er e

v

e

r

y 25 hours of use

and cleaned if ne

c

essa

ry. I

f the air

con

tains a

f

r

eque

ntly.

out.

4. A

ssemble in

r

e

v

erse o

r

de

r.

9.5 Maintenance of the spark plug (Fig. 27)

Spa

r

k plug spa

rk

ing gap = 0.6mm.

T

igh

t

en the

spa

r

k plug with a

tor

que of 12

t

o 15 Nm. Check

the spa

r

k pl

u

g f

or

d

ir

t and

g

rim

e af

t

e

r

10 h

ours o

f

ope

r

ation and if ne

c

essa

r

y clean it with a

c

opper

wi

r

e brush.

T

he

r

eaf

t

e

r

se

rvic

e the

s

pa

rk

plug af

t

er

e

v

e

r

y 50 hours of ope

r

a

tion.

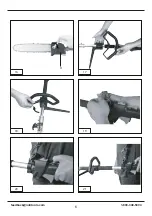

1.

P

ull out the spa

r

k boot plug (

Fi

g. 28).

2. R

em

ov

e the spa

r

k plug (

Fi

g. 28) with the

supplied

multifun

ction tool (It

em 24).

3. A

ssemble in

r

e

v

erse o

r

de

r.

9.6 Applying grease to the gear unit

A

f

t

er e

v

e

r

y 20 hours of use add a little gear

g

r

ease (app

ro

x. 10 g.) at the lub

ric

ation nipple

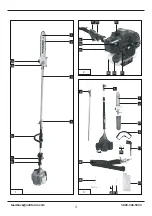

(Fi

g

. 4/It

em 25).

10. Cleaning, storage, transport

10.1 Cleaning

•

R

egula

r

ly clean the

t

ensioning mechanism

by bl

o

wing it out with

c

omp

r

essed air or

cleaning it with a brush.

D

o not use a

ny tools

1-800-348-5004

15

Summary of Contents for BlueMAX 53542

Page 4: ...4 5 4 3a 3b 25 4 6 8 5 K I N G R G H 7 9 1 800 348 5004 feedback natitools com 4...

Page 5: ...2 mm 10 12 14 11 13 15 1 2 L S L P S O M 1 800 348 5004 feedback natitools com 5...

Page 6: ...16 18 20 17 19 21 O 1 800 348 5004 feedback natitools com 6...

Page 7: ...23 25 27 24 26 a b T 22 1 800 348 5004 feedback natitools com 7...

Page 8: ...29 28 30 13 1 800 348 5004 feedback natitools com 8...