P31 PUMP ENDS

A. Preliminary

B. Disassembly

C. Inspection of Components

D. Reassembly

E. Testing and Final Adjustments

5A Preliminary

Before attempting any service on the

pump or motor, disconnect the elec-

trical power to the pump motor. If the

pump and motor are to be removed

as a unit, note the wiring configura

-

tion. Use colored or numbered tape

to mark the wire connections of the

motor and power source, for recon-

nection. If the pump is being used to

pump hot liquid, let the pump and liq-

uid cool before starting disassembly.

1. Disconnect the inlet and outlet pip-

ing before unbolting the pump and

motor. If the pipes are corroded,

use penetrating oil on the threads

to aid in removal.

2. Unbolt the motor from the base

and remove the unit. All work on

the unit should be performed on

an elevated workbench whenever

possible.

5B Disassembly

The following tools and equipment

are needed for disassembly/reas-

sembly of P31 Series Pumps:

1. Soft plastic or wooden mallet.

2. Small Punch.

3. 5mm hex wrench.

4. 3/16” hex wrench.

5. Snap ring pliers.

6. Penetrating oil.

7. 11/16” wood dowel (Approx. 6”

long.)

8. Thin blade screwdriver.

9. Cealube G, P-80, or glycol base

lubricant compatible with the pro-

cess fluid and O-ring elastomers.

(DO NOT use petroleum prod-

ucts.)

To disassemble the pump:

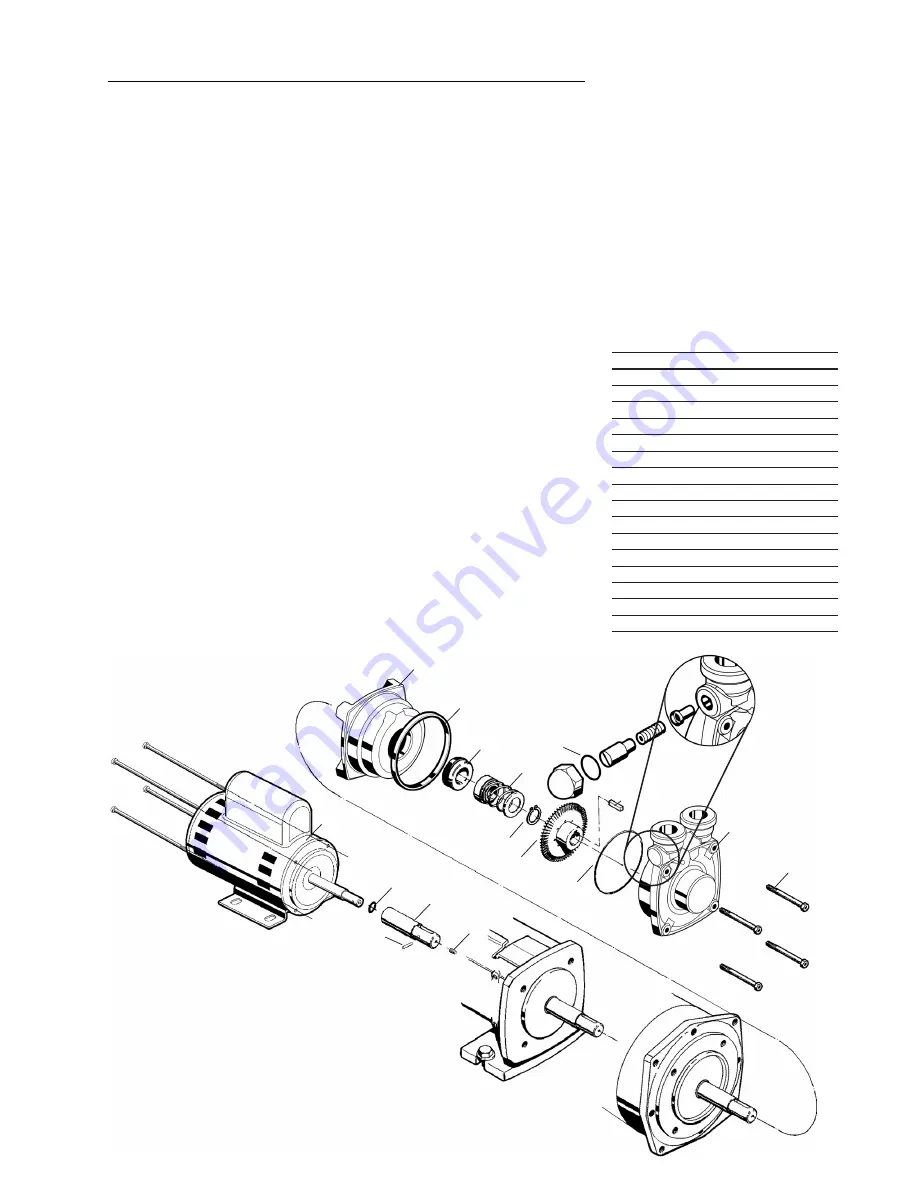

Refer to Figure 5-1 for reference to

the numbered parts in the procedures

below. Please note that the P31 is

an adjustable performance pump. It

has been preset at the factory for

your particular performance needs.

If you are disassembling for inspec-

tion or seal replacement only, you

may wish to mark or otherwise lock

the adjusting nut (#110) into place

(before disassembly) especially if you

are uncomfortable with the readjust-

ment procedures found in Section 5D

Step 10.

1. Remove all liquid from the pump.

Air blown through the pump will

remove fluid quickly.

2. Remove the four (4) M6-1 X

60mm bolts (#33) from the casing

(#108).

Page 509

Figure 5-1

125

84

12

4

11

23

7

108

33

8

88

19

72

NAME/DESCRIPTION

PART NO. QTY.

Motor Bracket

84

1

Casing

108

1

Adjusting Nut

110

1

“O” Ring/Casing

7

1

“O” Ring/ Relief Valve

7A

1

“O” Ring/Shaft Sleeve

8

1

Snap Ring

4

1

Impeller

11

1

Seal Rotating Element

12

1

Seal Stationary Seat

125

1

Setscrew

15

1

Thru Bolt/Casing

33

4

Thru Bolt/Motor

19

4

Shaft Sleeve

88

1

Shaft Sleeve Pin

72

1

Key/Impeller Drive

23

1

P31 CLOSE-COUPLED PUMP

110

P31 SERIES

5.

Service

15

7A