59

บᑥ

OILS

4

บᑥ

OILS

4-1

ܟบ

Recommended Oils

ፈบɂ˩᚜ɁܟบɥΈႊȪȹȢȳȨȗǿܟบ͏۶Ɂบ

ɥΈႊȬɞȻǾൡಽట఼ɁॴᑤɥऀȠҋȮȽȗکնȟȕɝɑ

Ȭǿ

Use the following recommended oils. Using other oils may

degrade the machine performance.

7

า

7

CAUTION

ȧΈႊȾȽɞบᑥ᭒ȾȷȗȹɂǾɴɮʵʫ˂ɵ˂Ɂ

MSDS

ᴥԇޙ࿎ኄާпʑ˂ʉʁ˂ʒᴦɥ᠔оЫȞɜȝറᒲᡵȺо

ਖ਼ɁșțǾȝറɁ͖ȾȝȗȹͽഈၥہɁᆬίɗίከȝɛ

ɆࣔȾᩜȪȹɁከျɥᚐȶȹȢȳȨȗǿ

MSDS

ȾᜤᢐȨɟ

ȹȗɞ̷ͶɋɁफᬭȾȷȗȹɕԚґȧาȢȳȨȗǿ

Receive the MSDS (MATERIAL SAFETY DATA SHEET)

from the lubricant manufacturer directly yourself as the

customer. Work environment management and the

storage and disposal of oils are the sole responsibility of

the customer. Take careful note of the effects on the

human body described in the MSDS.

2

าᜤ

2

NOTE

ͅʫ˂ɵ˂ɁบɥຉնȪȽȗȺȢȳȨȗǿ

Do not mix different brand oils.

4-2

ɴɮʵʫ˂ɵ˂ߦ᚜

Oil Equivalents

ՎᐎɑȺȾյɴɮʵʫ˂ɵ˂Ɂบߦ᚜ɥ͏˩ȾᇉȪɑȬǿ

ܟบ͏۶ɁบȾȷȗȹɂᤆӦ࿑ॴɥίᜳȬɞɕɁȺɂȕɝ

ɑȮɦǿ

The following table shows equivalent product names for your

information. The oils other than recommended oils are not

guaranteed on the dynamic characteristics.

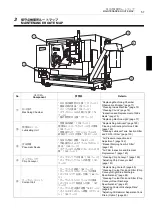

ፈบኙ

ሗҝ

บᦀᴥ

L

ᴦ

̬૰֚ఙ

ፈบ֚ఙ

༁໙บʰʕʍʒʉʽɹ

ல֪ʁɱʵᆀบ

ʁɱʵʒʔ

S3 M 68

4

—

॒ᛵȾख़ȫȹ

บ٢ʰʕʍʒʉʽɹ

ҋбᒾႇ

ʊʟʕ˂ʙɮʓʷɰʴʍɹʟ

ʵɮʓ

32

10

ሜЄᩖ

2000

ᩖ

—

ѯԵบຣ࣊ɽʽʒʷ˂ʳʉʽ

ɹ

ҋбᒾႇ

ʊʟʕ˂ʃ˂ʛ˂ʨʵʋɴɮ

ʵ

2M

10

ሜЄᩖ

2000

ᩖ

—

ʋʭʍɹ

ல֪ʁɱʵᆀบ

ɬʵʚʕɬ

HDX

ʋʭʍɹ͇ࠖɁᝢంՎྃ

ِްળɟඨɔɁʷ˂ʳʟɳʷ

ɬᴥɴʡʁʱʽᴦ

ɬʵʚʕɬɺʴ˂ʃ

No.2

ɑ

Ȳɂᄾछֿ

ᤛᦀ

—

ුஓ

Lubricating Point

Type

Quantity (L)

Oil Change Inter-

val

Replenishing

Interval

Lubricating Unit Tank

Shell

Shell Tonna S3 M 68

4

—

As required

Hydraulic Unit Tank

Idemitsu

Daphne Hydraulic Fluid 32

10

Every 2000 hours

of operation

—

Oil Temperature Controller

Tank

Idemitsu

Daphne Super Multi Oil 2M

10

Every 2000 hours

of operation

—

Chuck

Shell

Alvania HDX

Refer to the chuck manufacturer's manual

Roller Follower of the Steady

Rest (Option)

Alvania Grease No. 2 or

equivalent

As required

—

Everyday

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......