55

ίަཟ೫ᬱᄻˢᜄ᚜

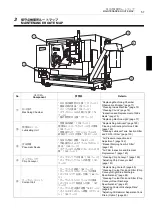

REGULAR INSPECTION LIST

1000

ᩖ

ຏો

ʋʭʍɹɁґᜓຏોᴥʋʭʍɹɁᝢంᴦ

บ٢ʰʕʍʒ

༁໙บʰʕʍʒʉʽɹɁຏોᴥ

ᆬᝓ

ሳ٢ᚽᏚʟɭʵʉɁཟ೫ᴥ

ᯚ٢ɹ˂ʳʽʒᚽᏚ

“V

ʣʵʒɁཟ೫

”

ʤ˂ʂᴦᴥɴʡʁʱʽᴦ

̬૰

1500

ᩖ

ຏો

2000

ᩖ

̬૰

บ٢ʰʕʍʒ

1

ᩖ

ᆬᝓ

ӏࡾюᆬᝓሻɁཟ೫

Έႊᩒܿऻ

2

ᵻ

3

Ȟఌ

ᝩ

ᴥқఙͩɆᴦᴥɴʡʁʱʽᴦ

1

ࢳ

̬૰

บ٢ʰʕʍʒ

ᝩ

ʤ˂ʂᴦᴥɴʡʁʱʽᴦ

ᴲࢳ

̬૰

Inspection

Interval

Inspection Item

As Required

Lubrication

“Replenishing Coolant” (page 85)

Hydraulic Unit “Checking Oil Level/Replenishing Oil” (page 94)

“Replenishing Lubricant” (page 129)

Semi Dry-Cut System “Replenishing Oil” (page 140) (Option)

High Pressure Coolant Unit “Replenishing Coolant to Clean Tank” (page 164) (Option)

Replacement

“Replacing Machine Light” (page 77)

Adjustment

“Adjusting Coolant Discharge Rate” (page 89)

“Adjusting Oil Skimmer Separation Tank Drain (Option)” (page 90)

Semi Dry-Cut System “Adjusting Oil Supply Quantity” (page 140) (Option)

High Pressure Coolant Unit “Suction Pressure Inspection and Adjustment” (page 163)

(Option)

Cleaning

Cleaning spindle drain hole (page 72)

Cleaning tailstock spindle drain hole (Built-in type) (page 73)

“Cleaning Coolant Gun” (page 92) (Option)

Cleaning hydraulic unit radiator (page 96)

Manual draining from pneumatic device air filter (page 143)

Confirmation

“PREPARATION FOR MACHINE OPERATION AFTER PROLONGED IDLE PERIOD”

(page 69)

Reaffirming machine level (Separate volume, “INSTALLATION MANUAL”)

ίަ֚ఙ

ίަᬱᄻ

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......