18

MB300 XL Pro

rev.0.2 ID03570

5.3 PNEUMATIC SPECIFICATIONS

Provided the devices and pneumatic circuits can work reliably, efficiently and safely, you need

the compressed air used for pneumatic system supply to have the following quality requirements

according to DIN ISO 8573-1:

▪

Air quality provided to the binder CLASS 3,

▪

Dust: 5 micron - 5 mg/m3

▪

Water: -20°C - 0.88 g/m3

▪

Oil: 1 mg/m3

The air compression system upstream of the machine book binder machine must have a dryer.

Periodically check quality of the compressed air supplied to the machine and the operating values.

Operating pressure

The user’s pneumatic system must guarantee the following values at the compressed air input

joint of the binder:

▪

7 bar;

▪

guarantee air consumption equal to 200 l/min

▪

air quality: Class 3

Pneumatic features of the machine:

Compressed air consumption 150 l/min

Input gauge calibration 6 bar

Minimum working pressure 5.5 bar (if pressure goes below this pressure, the machine goes to

alarm status)

Air input coupling diameter 10 mm

The compressor connection tube diameter 10 mm is not supplied with the machine.

A compressor is recommended with an automatic condensate drain. This avoids checking

for water inside the compressor tank each week.

If the compressor is placed inside the company, you are advised to purchase a silent

compressor.

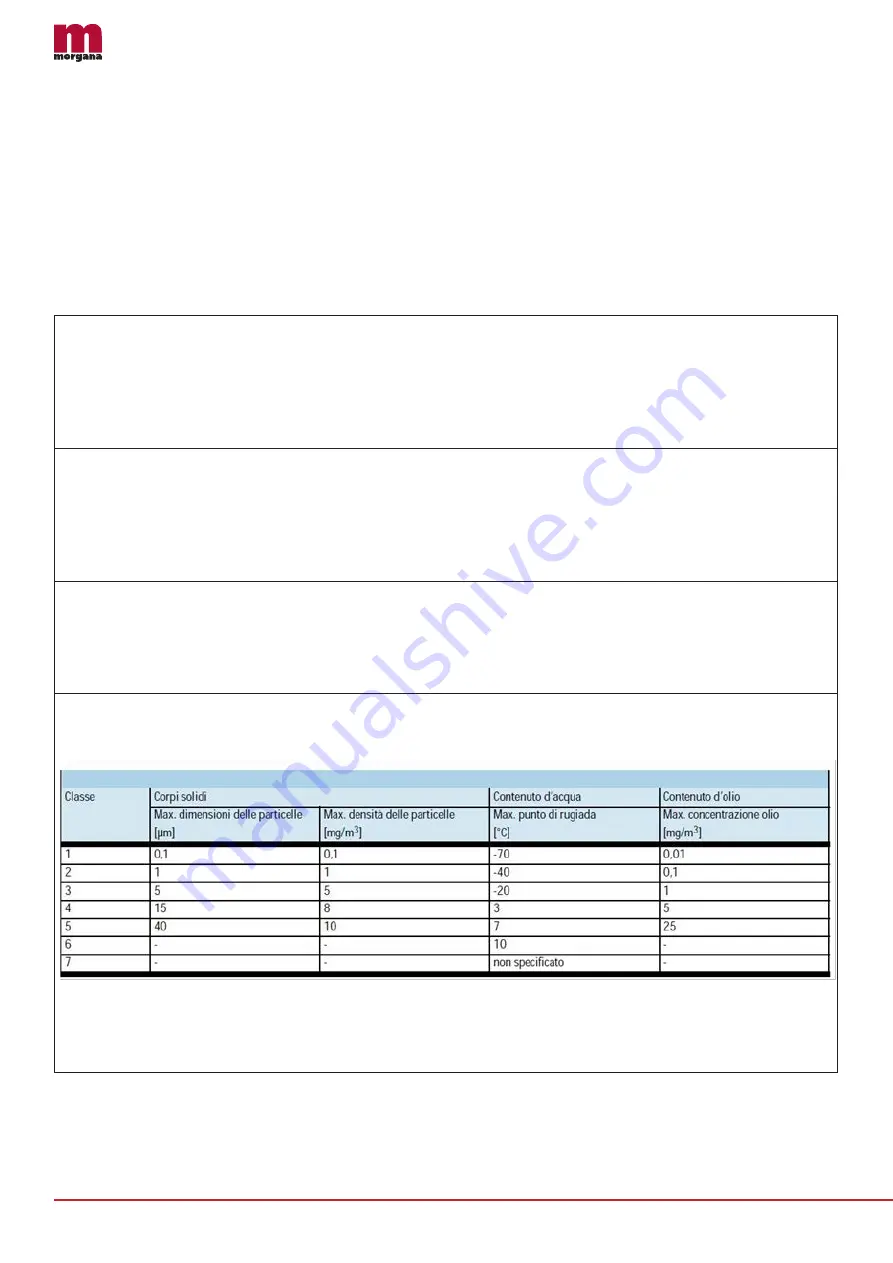

Standards DIN ISO 8573-1 - Air quality classes

The manufacturers of the pneumatic parts refer to the quality of the compressed air to use for

their products, taking into consideration the table below.

The compressed air used in an industrial environment contains water, oil, dust and other

impurities. The interaction of these elements produces an aggressive mix that causes

deterioration of compressed air-operated equipment and also the PUR glue contained in the

PUR tank, resulting in poor working quality and an increase in maintenance costs.