–

–

'14 • KX-SM-200

: Compressor ON output

·It is turned ON, when the compressor is ON

: Oil return operation output

·It is turned ON at oil return operation in cooling or at oil return operation in heating, or at defrost operation in heating.

: When HP is relatively high

·Signal is output in order to operate a sprinkler system for cooling down the heat source unit heat exchanger.

It is turned ON, when high pressure > .MPa in cooling mode

If once starting operation of sprinkler system, it shall be kept operation for 0sec at least.

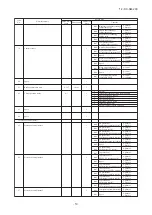

(6) Pump down control for replacement (Master unit/slave unit)

This control is for recovering refrigerant to heat source unit quickly in case of replacement or relocation of the heat source unit.

(a) This control is performed from the master unit side. It cannot be controlled from the slave unit side. If this control is at-

tempted from the slave unit side, the following codes are displayed on the -segment LED of the slave unit.

Note (1) The display returns to normal if the pump-down control switch is reset.

(b) Pump down operation can be performed with the operation of dip switches SW-1(Test run switch), SW- (Test run

operation mode) and SW- (Pump down switch)

(c) Pump down procedure

1) Shut the liquid side service valve on the heat source units

) Turn SW- (test run operation mode) ON (cooling)

) Turn SW- (pump down switch) ON

) Turn SW-1 (test run switch) ON

(d) End condition

If any of the following conditions is satisfied, this control ends.

(i) When the low pressure (LP) is preset value or less, this control ends normally, and indicates followings

①

Red LED: Keeps lighting

②

Green LED: Keeps flashing

③

-segment display: PdE

④

Remote control: Stop

(ii) Anomalous all stop by the error detection control. Auto backup operation, however, depends on the dip switch setting.

(iii) If the cumulative compressor operation time under pump down control is 1minutes (End control because time is

up), this control ends and indicates followings

①

Red LED: Stays OFF

②

Green LED: Keeps flashing

③

-segment display: No display

④

Remote control: Stop

(iv) When any of setting switch (SW-1, SW-, SW-) is turned OFF during pump down control.

(Note) Even if only SW- is turned OFF, it is not recognized as the cooling test run mode and it stops.

Code display area

Data display area

Contents of invalid operation

oPE

10

Setting from the slave unit is invalid

Summary of Contents for FDC1000KXZWE1

Page 171: ... 14 KX SM 200 169 ...

Page 172: ... 14 KX SM 200 170 ...

Page 173: ... 14 KX SM 200 171 ...

Page 174: ... 14 KX SM 200 172 ...