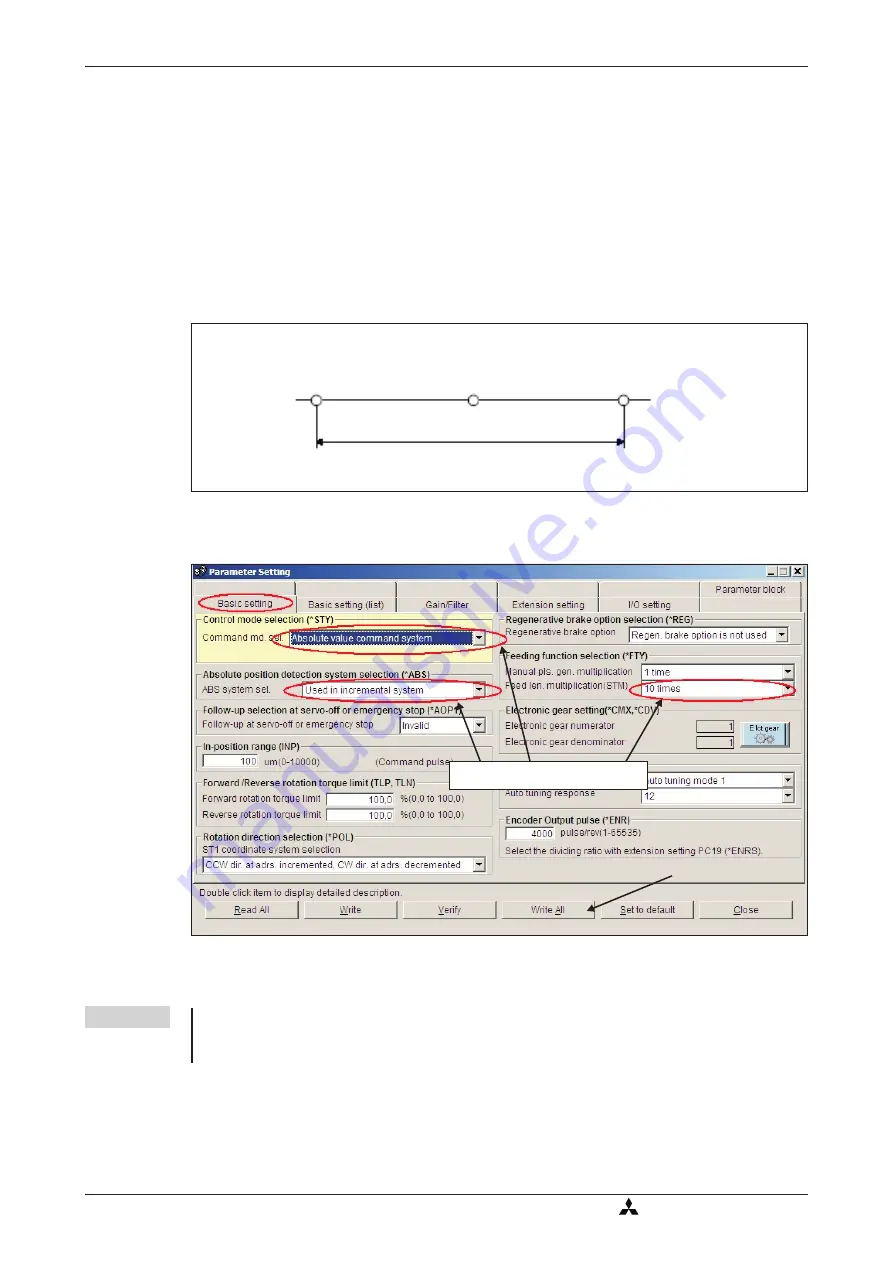

The following example shows some typical configuration settings used for many common posi-

tioning applications:

Procedure:

햲

Select the incremental system for positions with PA03 *ABS.

햳

Select absolute value command mode for target positions with PA01 *STY.

햴

Set a multiplication factor with PA05 *FTY = 1 => 10 times factor.

This gives us the following position system:

NOTE

If target positions are entered using the incremental system it is not possible to change the

rotation direction via the point table. In this mode the rotation direction can only be changed

with the start commands (ST1/ST2).

Configuration for Positioning

Positioning with Digital Inputs

4 - 24

MITSUBISHI ELECTRIC

Fig. 4-13: Effective range of the position values with the sample settings

Min. absolute value

−

9999.99

Max. absolute value

+9999.99

0

Range of possible position values

in [10

STM

µm]

Fig. 4-14: Relevant parameters affecting the target position setpoint values

���

���

Parameter settings for example