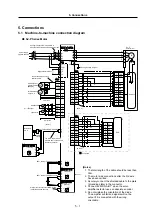

5. Connections

5

−

1

5. Connections

5.1 Machine-to-machine connection diagram

●

SJ-P Series Motor

L11

L21

C

D

P

Regenerative resistor

L1

L2

L3

U

V

W

Power supply

3-phase 200VAC

NFB

T E 1

T E 2

Detector

MC

Configure a sequence in which MC is

disconnected by alarms and emergency stops.

1 1

2 0

6

1 6

7

1 7

H

K

A

N

C

R

E

P5

5G

MA

MA*

MB

MB*

SHD

B

24G

MOH

MZ

MZ*

1

1 0

1 8

8

P

5

1 5

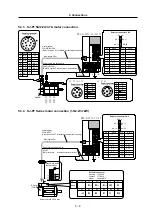

SJ-P

Series Motor

P5

5G

MA

MA*

MB

MB*

SD

5G

P5

MZ*

MZ

24G

MOH

PE

PE

C N 2

Class 3 grounding or higher

Cable

clamp

CN

1A

Mitsubishi

CNC

M D S - B - S V J 2

CS1

0

(1st axis)

CN

1A

CN

1B

(Note 1)

CS1

1

M D S - B - * *

CS1

2

CN1

A

CN

1

B

CS1

n-1

Always insert a terminator (MDS-A-TM)

in CN1B at the end. (Note 4)

(nth axis)

CN

1A

CN

1

B

CN

1B

SH21 cable or FCUA-R000 cable

SH21 cable or FCUA-R000 cable

Spindle amplifier

M D S - B - S P J 2

M D S - B - * *

A

B

C

D

U

V

W

E

F

G

(Note 3)

(Note 2)

I M

ENC

H

K

A

N

C

R

P5

5G

PA

PA*

PB

PB*

B PZ

PZ*

P

1 1

2 0

4

1 4

3

1 3

1

1 0

1 2

2

P5

5G

PA

PA*

PB

PB*

SD

5G

P5

PZ*

PZ

C N 2

(Note 3)

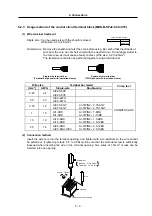

※

Full closed

Speedometer

V

0~10V

output

C N 3

1 0

1 1

P24

24G

MO1

5G

MO2

5G

SD

9

1

1 9

1

2m or less

1 4

MCON

Do not connect when using

external power.

5m or less

External power

magnetic switch

(Note 5)

Miscellaneous

output 1, 2

Load meter

V

MC

RA

8

DO1

1 8

DO2

SH21 cable or FCUA-R000 cable

(3rd axis)

Plate

Plate

Plate

The SH21 cable from the

previous axis is connected to

the CN1A connector.

(Notes)

1. The total length of the cable should be less than

30m.

2. The motor side connections after the 3rd axis

have been omitted.

3. Securely connect the shielded cable to the plate

(grounding plate) in the connector.

4. Connect an MDS-A-BT* when the servo

amplifier detector uses an absolute encoder.

5. Do not mistake the orientation of the diode.

The amplifier will fail and signals will not be

output if it is connected with the wrong

orientation.