Ê

Applying Threadlocker

NOTE: The following threadlocker information and

illustrations are excerpts from the Loctite

®

User’s

Guide and are used with permission.

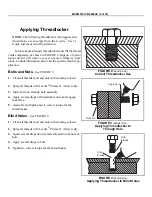

For maximum strength, threadlocker must fill the thread

voids completely, as shown in FIGURE 2. Organic or petro-

leum solvent will remove excess uncured adhesive from

joints. Consult information below for the specific fastener ap-

plication.

Ë

Bolts and Nuts

—See FIGURE 3.

1. Clean all threads (bolt and nut) with cleaning solvent.

2. Spray all threads with Loctite

®

Primer N. Allow to dry.

3. Insert bolt into through hole assembly.

4. Apply several drops of threadlocker onto bolt engage-

ment area.

5. Assemble and tighten nut to correct torque for the

threadlocker.

Ë

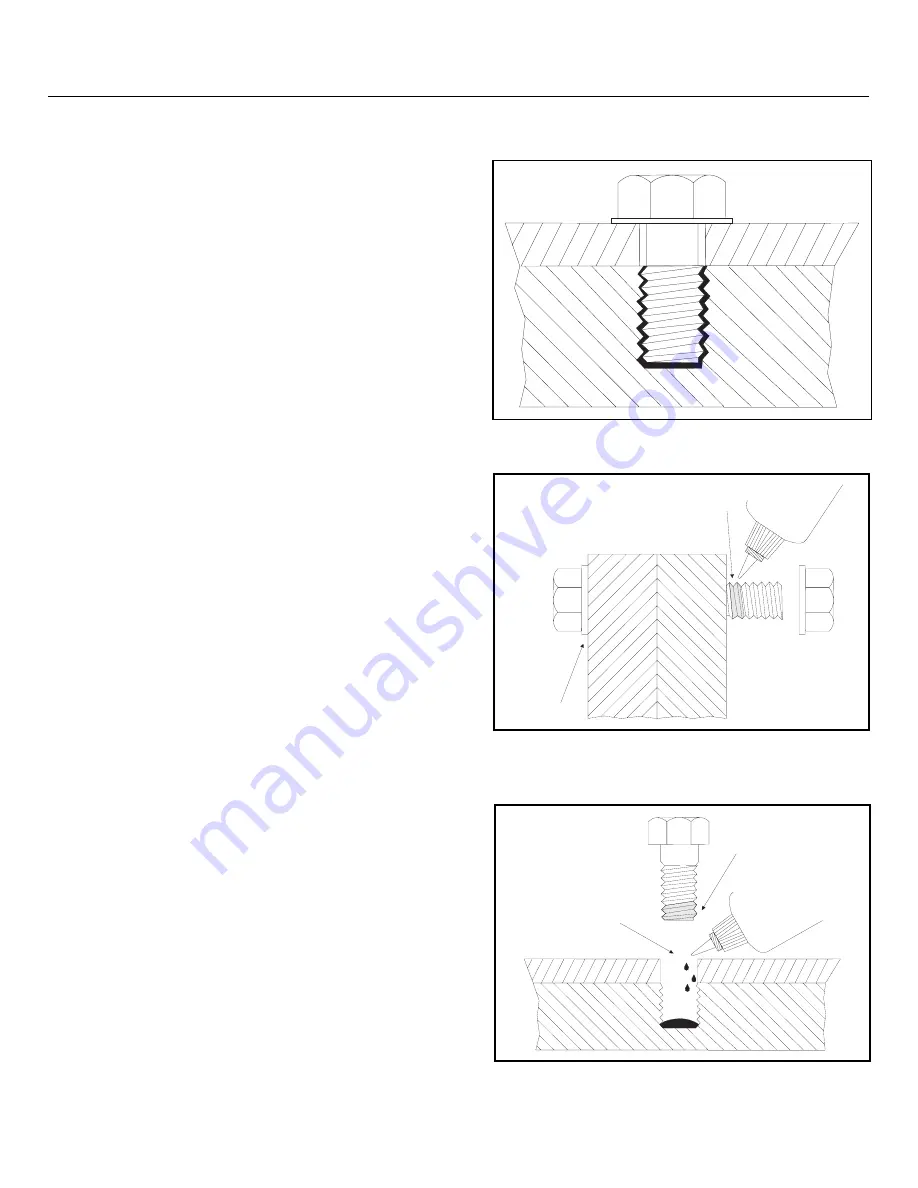

Blind Holes

—See FIGURE 4.

1. Clean all threads (bolt and nut) with cleaning solvent.

2. Spray all threads with Loctite

®

Primer N. Allow to dry.

3. Squirt several drops down female threads into bottom of

hole.

4. Apply several drops to bolt.

5. Tighten to correct torque for the threadlocker.

Î

FIGURE 2

(MSSM0101CE)

Î

Correct Threadlocker Use

Apply here

Not here

Î

FIGURE 3

(MSSM0101CE)

Î

Applying Threadlocker to

Through Hole

Onto

threads

Onto

threads

Î

FIGURE 4

(MSSM0101CE)

Î

Applying Threadlocker to Blind Holes

MSSM0101CE/9906AV (2 of 19)

Summary of Contents for 30015

Page 6: ......

Page 8: ......

Page 10: ......

Page 19: ...Section 1 Service and Maintenance ...

Page 51: ...Section 2 Drive Assemblies ...

Page 59: ...BMP950003 95107V Page 1 MOTOR MOUNT 30015 30020 S4A S4G S4J S4T ...

Page 68: ......

Page 69: ...Section 3 Bearing Assemblies ...

Page 72: ...BMP910032 96141V Page 1 MAIN BEARING ASSEMBLY 30015C4x M4x K5x S5x ...

Page 74: ...BMP910033 96141V Page 1 MAIN BEARING ASSEMBLY ...

Page 76: ...BMP910034 95116V Page 1 MAIN BEARING ASSEMBLY 30015M6x ...

Page 80: ...BMP910035 93251V Page 1 JACKSHAFT ASSEMBLY 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 82: ......

Page 83: ...Section 4 Shell and Door Assemblies ...

Page 86: ...BMP920009 94491V Page 1 DOOR ASSEMBLY 30015 30020 RIGID MOUNT WASHER EXTRACTORS ...

Page 90: ......

Page 91: ...Section 5 Control and Sensing Devices ...

Page 100: ...BMP920010 97281V Page 1 COIN ASSEMBLY INSTALLATION 240V 30015 30020 30022 COIN MACHINES ...

Page 105: ...Section 6 Chemical Supply Devices ...

Page 113: ...Section 7 Water and Steam Piping and Assemblies ...

Page 114: ...ISOMETRIC SYMBOLS STANDARD SYMBOLS BMP920008 93027V Page 1 SCHEMATIC SYMBOLS KEY ...

Page 132: ...BMP920021 93251V Page 1 STEAM INSTALLATION 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 138: ...BMP920017 93251V Page 1 ELECTRIC DRAIN VALVE 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...