108

Alert information,

Continued

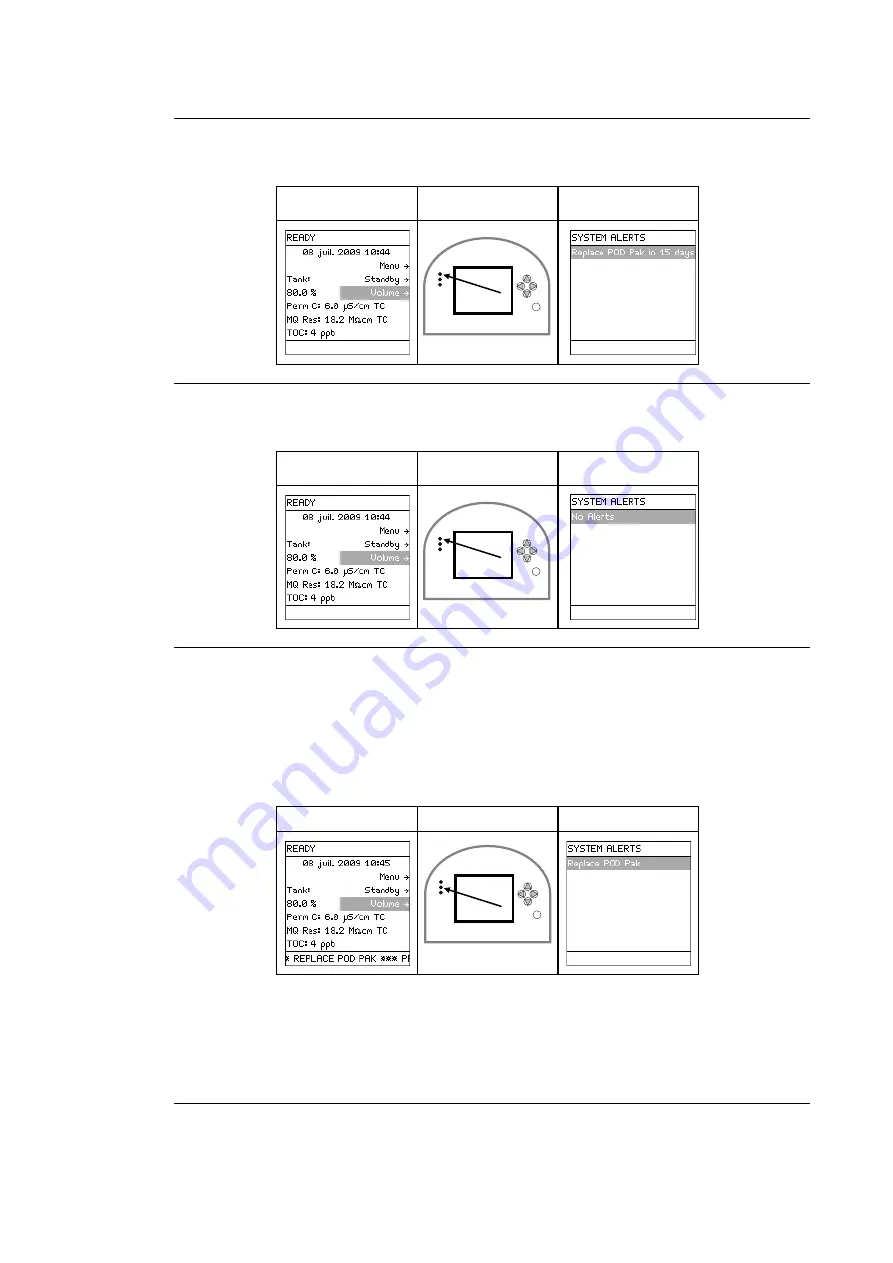

Minor Alert -

after cancelling

The Alert message has been cancelled but the cause of the message is still active.

Main Display

LEDs

Main Display

Minor Alert -

consumable

replaced

The Alert message has been cancelled when the POD Pak has been replaced.

Main Display

LEDs

Main Display

Cancelling a

Major Alert

message -

procedure

A Major Alert message can be cancelled by:

•

performing the maintenance action (i.e. replace consumable), or

•

using the Keypad. This cancels the display of the Major Alert message for 24 hours.

Example: Before cancelling, the Major Alert message is REPLACE POD PAK.

Main Display

LEDs

Main Display

A Major Alert message can be cancelled using the Keypad. This is done in the same way

that a Minor Alert message is cancelled.

The display of the Major Alert is cancelled for 24 hours. It appears again after 24 hours

unless the maintenance action is performed.

Continued on next page

ê

ê

ê

Summary of Contents for Direct 16

Page 1: ...User Manual Milli Q Direct 8 16 System...

Page 2: ......

Page 6: ......

Page 47: ...Milli Q Direct 8 16 System 47 Software Map Map...

Page 115: ......

Page 116: ...Milli Q Direct 8 16 System FTPF11486 V3 0 03 2013...