4

TABLE 2 - Technical specifications of electrical cables

Connection

Type of cable

(minimum section values)

Max. admissible length

A

- Power line

Cable 3 x 1.5 mm

2

30

m

(note 1)

B

- FLASH flashing light output

Cable 2 x 0.5 mm

2

20

m

C

- Radio aerial

RG58 type shielded cable

20 m (less than 5 m recommended)

D

- input/output ECSbus

Cable 2 x 0.5 mm

2

20

m

(note 2)

E

- STOP input

Cable 2 x 0.5 mm

2

20

m

(note 2)

F

- OPEN input

Cable 2 x 0.5 mm

2

20

m

(note 2)

G

- Motor output M1

Cable 3x1 mm

2

10

m

Note 1

- If the power cable is longer than 30 m, a cable with a larger section is required (e.g. 3x2.5 mm

2

) and safety earthing is necessary in the

vicinity of the automation.

Note 2

- For cables of ECSbus and those of the STOP and OPEN inputs, a single cable with multiple internal wires may be used, to combine

several connections: for example, the STOP and OPEN inputs can be connected to the KS100 selector switch with a cable of 4 x 0.5 mm

2

.

CAUTION! – The cables used must be suited to the installation environment: for example a cable type H03VV-F is recommended for

indoor environments, and a cable type H07RN-F for outdoor environments.

––– STEP 4 –––

4.1 - PRELIMINARY CHECKS FOR INSTALLATION

4.1.1 - Establish the position of devices in the system

With reference to

fig. 1

and

5

, locate the approximate position for instal-

lation of each device envisaged in the system.

Fig. 1

shows a system

made using this product and other optional accessories in the Mhouse

range. These elements are positioned according to a typical standard

layout. The components are:

[

a

] - 1 FL100 flashing light with integrated aerial

[

b

] - 1 pair of PH100 photocells (one TX and one RX)

[

c

] - 1 KS100 key-operated selector switch

[

d

] - 2 photocell posts

[

e

] - WS1SC Gearmotor equipped with integrated CLS2 control unit

[

f

] - WS1SK Gearmotor

[

g

] - Closing stop (not included)

WARNING! - Some of these devices are optional and may not be

present in the kit (see Mhouse product catalogue).

WARNINGS:

• The gearmotor must be anchored to the ground, laterally to the gate

using the related fixing plate.

• The fixed control devices must be positioned:

- in sight of the automation;

- far from moving parts;

- at a height of at least 1.5 m from the ground;

- not accessible by the public.

4.1.2 - Establish the position of all connection cables

Refer to the instructions in paragraph 4.2 to establish the layout of the

raceways for electric cable ducting.

4.1.3 - Ensure all equipment and materials for work are available

Before starting work, ensure that you have all equipment and materials

required to complete the work. Ensure that all items are in good condition

and comply with local safety standards.

4.1.4 - Completing the set-up work

Prepare the area for subsequent installation of the devices, completing all

preliminary work, such as:

- digging of raceways for protection ducting of electric cables (external

ducting may be used as an alternative);

- laying of protection ducting and embedding in concrete;

- sizing of all electric cables to required length (see paragraph 4.2) and

routing in protection ducting.

Caution! - In this phase, do not make

any electrical connections.

Warnings

:

• The hoses and ducting serve to protect electrical cables and prevent

accidental damage in the event of impact.

• When laying pipelines, take into account the risk of possible deposits of

water in the branch wells, where condensate may form in the pipelines

and the control unit with possible damage to the electronic circuits.

• Position the ends of the ducting at the points envisaged for fixture of

the various components

4.2 - PREPARING ELECTRIC CABLES

To prepare all connection cables, proceed as follows.

a)

- Refer to

fig. 5

to check the connections of the various devices to the

control unit and terminals to be used for each connection.

Impor-

tant

- Only devices using “ECSbus” technology can be connected to

the terminal “ECSbus”.

b)

- Refer to

fig. 1

to check positions of the electrical cables in the area.

Then draw a similar diagram on paper, adapting it to specific require-

ments of your system.

Note

- This diagram will be useful to establish

the route of the raceways for cable ducting, and to draw up a com-

plete list of the cables required.

c)

- Read

Table 2

to determine the type of cables to be used; then refer

to the diagram drawn above and on-site measurements to deter-

mine the length of each cable.

Caution! - No cable must exceed

the specific maximum length stated in Table 2.

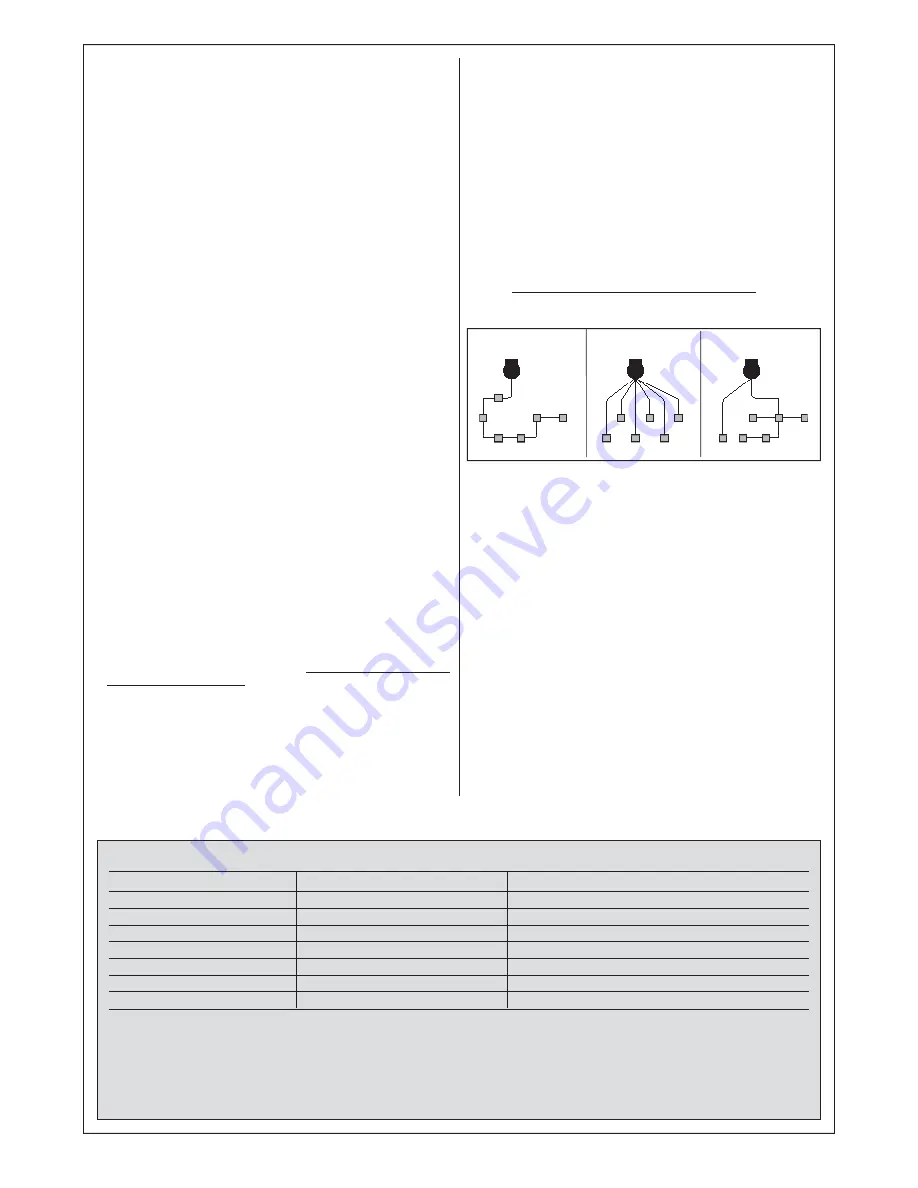

WARNING

-

“ECSbus” technology enables the interconnection of devic-

es using a single “bus” cable, with 2 internal electrical wires. Connection

of several devices can be in the configuration “

cascade

”, “

star

” or the

latter two “

combined

”.

cascade

star

combined

Summary of Contents for MhouseKit WS2S

Page 2: ......

Page 7: ...5 D G B C D D E F a d g d e f b b c 1 3 4 5 A B E H F I 2 L G D C A...

Page 9: ...7 8 10 NO 11 E D C 12 13 9 A B F G...

Page 10: ...8 M L 15 17 N O P 16 Blue Yellow Green Brown 18 19 I 14 H H...

Page 30: ...28...

Page 34: ......

Page 35: ......