16

10.1.2 - Checking settings via a radio transmitter

With a radio transmitter memorised in Mode 1 the user can check settings

at any time for each parameter, as follows:

To display the parameters, see Table 5:

01.

Press T1 and T2 simultaneously on the radio transmitter for at least

5 s.

02.

Release the two keys.

03.

Within three seconds, complete the action as specified in

Table 5

according to the parameter to be checked.

04.

Release the key when the flashing light starts to flash.

05.

Count the number of flashes and, according to the number, check

the corresponding value on Table 3.

Example: After pressing T1 and T2 for 5 s followed by T1, if the flashing

light flashes three times, the pause time is set at 40 s.

To display the parameters, see Table 6:

01.

Press T1 and T3 simultaneously on the radio transmitter for at least

5 s.

02.

Release the two keys.

03.

Within three seconds, complete the action as specified in

Table 6

according to the parameter to be checked.

04.

Release the key when the flashing light starts to flash.

05.

Count the number of flashes and, according to the number, check

the corresponding value on Table 4.

10.2 - OPTIONAL ACCESSORIES

As well as the devices in WS2S, there are a number of optional accessories

which may be used to integrate the automation system.

PR1:

24 V buffer battery; in the event of a mains power failure, this guar-

antees at least 10 complete cycles.

PF:

24 V solar power system; useful in cases in which there is no electri-

cal mains power.

PT50:

Pair of columns (height 500 mm) with photocell

PT100:

Pair of columns (height 1,000 mm) with two photocells

For information on the new accessories, refer to the MHOUSE catalogue

or visit the website www.mhouse.com.

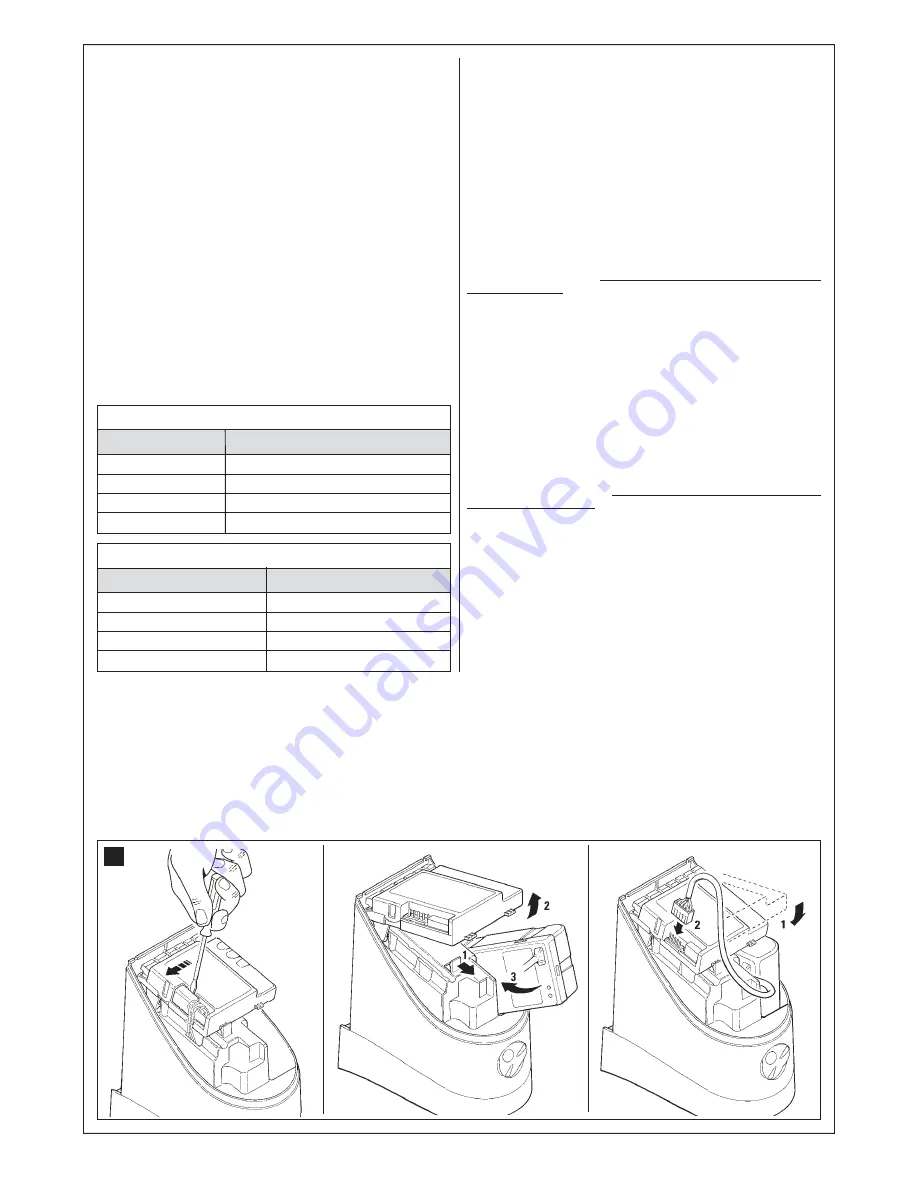

10.2.1 - Installing the PR1 buffer battery (fig. 31)

CAUTION! - The electric connection of the battery to the control

unit must only be made after completing all installation and pro-

gramming phases, as the battery constitutes an emergency power

supply.

To install and connect the buffer battery PR1 to the control unit, refer to

fig. 31

and the PR1 instruction manual.

When the automation is powered by the buffer battery, 60 seconds after

a manoeuvre is completed, the control unit automatically switches off the

output “ECSbus” (and all connected devices), output Flash and all leds,

with the exception of the ECSbus led, which flashes at slower intervals;

this indicates the “Standby” function. When the control unit receives a

command, it restores normal operation (with a short delay). This function

is used to reduce consumption; an important factor when the unit is pow-

ered by battery.

10.2.2 - Installing the PF solar power supply system (fig. 32)

CAUTION! - When the automation is powered exclusively by the

solar power system “PF”, IT MUST NEVER BE POWERED at the

same time by the mains.

To connect the PF solar power system to the control unit, refer to

fig. 32

and the PF instruction manual.

When the automation is powered by the solar panel, 60 seconds after a

manoeuvre is completed, the control unit automatically switches off the

output “ECSbus” (and all connected devices), output Flash and all leds,

with the exception of the ECSbus led, which flashes at slower intervals;

this indicates the “Standby” function. When the control unit receives a

command, it restores normal operation (with a short delay). This function

is used to reduce consumption; an important factor when the unit is pow-

ered by photovoltaic panels.

31

1

2

3

Parameter

Pause Time

Pedestrian opening

Motor force

“OPEN” function

Action

Press T1 and hold it down

Press T2 and hold it down

Press T3 and hold it down

Press T4 and hold it down

TABLE 5

Parameter

Discharge on closing Motor 1

Discharge on opening Motor 1

Discharge on closing Motor 2

Discharge on opening Motor 2

Action

Press T1 and hold it down

Press T2 and hold it down

Press T3 and hold it down

Press T4 and hold it down

TABLE 6

Summary of Contents for MhouseKit WS2S

Page 2: ......

Page 7: ...5 D G B C D D E F a d g d e f b b c 1 3 4 5 A B E H F I 2 L G D C A...

Page 9: ...7 8 10 NO 11 E D C 12 13 9 A B F G...

Page 10: ...8 M L 15 17 N O P 16 Blue Yellow Green Brown 18 19 I 14 H H...

Page 30: ...28...

Page 34: ......

Page 35: ......