4C - 20 - CHARGING SYSTEM

90-816462 2-695

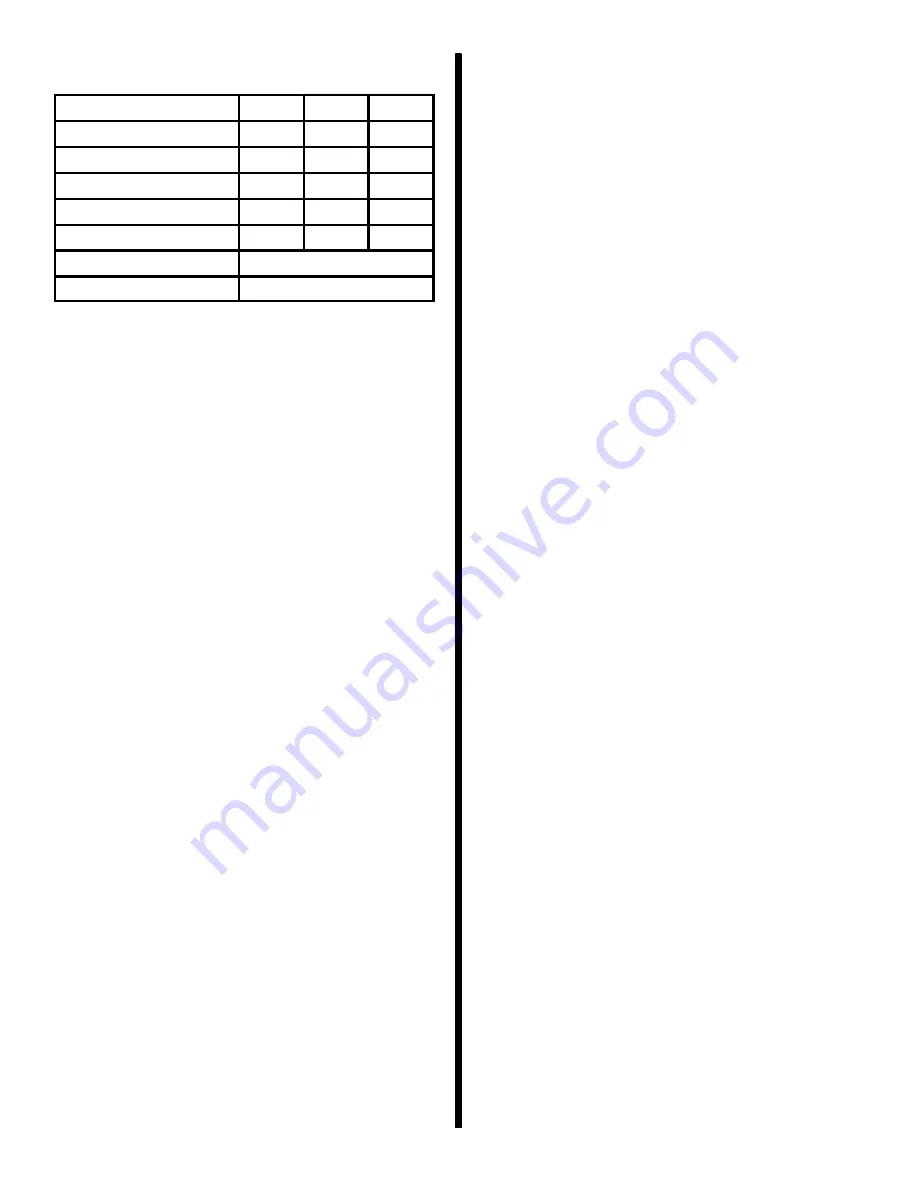

Torque Specifications

Fastener Location

Lb In.

Lb. Ft.

N·m

Housing Screws

55

6.5

Pulley Nut

42

58

Front Bearing Screws

Alternator Mount

35

48

Adjustment Bolt

16

28

All Other Fasteners

Tighten Securely

V-Belt Tension (Note)

Depress 1/2 In. (13mm)

NOTE: Depress belt with thumb at midway point be-

tween circulating pump pulley and alternator.

Description

The alternator has a rotor, which is supported in two

end frames by ball bearings, and is driven by a pulley

at approximately twice engine speed. The rotor con-

tains a field winding that is enclosed between two

multiple-finger pole pieces. The ends of the field

winding are connected to two brushes (mounted in

the rear end frame) which make continuous sliding (or

slipping) contact with the slip rings. The current (flow-

ing through the field winding) creates a magnetic field

that causes the adjacent fingers of the pole pieces to

become alternate north and south magnetic poles.

A 3-phase stator is mounted directly over the rotor

pole pieces and between two end frames. It consists

of three windings wound 120 degrees electrically

out-of-phase on the inside of a laminated core. The

windings are all connected together on one end, while

the other ends are connected to a full-wave rectifier

bridge.

The rectifier bridge contains six rectifiers which are

arranged so that current flows from ground, through

the stator and to the output terminal, but not in the op-

posite direction.

When current is supplied to the rotor field winding,

and the rotor is turned, the movement of the magnetic

fields created induces an alternating current into the

stator windings. The rectifier bridge then changes this

alternating current to direct current which appears at

the output terminal. A diode trio also is connected to

the stator windings to supply current to the regulator

and the rotor field during operation.

Voltage output of the alternator is controlled by regu-

lating the current supplied to the rotor field. This is ac-

complished by a transistorized voltage regulator that

senses the voltage at the battery and regulates the

field current to maintain alternator voltage within pre-

scribed limits for properly charging the battery. Cur-

rent output of the alternator does not require regula-

tion, as maximum current output is self-limited by the

design of the alternator. As long as the voltage is reg-

ulated within the prescribed limits, the alternator can-

not produce excessive current. A cut-out relay in the

voltage regulator also is not required, as the rectifier

diodes (which allow current to flow in one direction

only) prevent the battery from discharging back

through the stator.

Due to the lack of residual magnetism in the rotor pole

pieces, a small amount of current must be supplied to

the rotor field to initially start the alternator charging.

This is accomplished by means of an excitation circuit

in the regulator which is connected to the ignition

switch. Once the alternator begins to produce output,

field current is supplied solely by the diode trio, as ex-

plained, preceding.

The alternator also is equipped with a fan (mounted

on the rotor shaft) which induces air flow through the

alternator to remove the heat created by the rectifiers

and stator. A capacitor protects the rectifier system

from high voltages and suppresses radio noise.

Precautions

The following precautions MUST BE observed when

working on the alternator system. Failure to observe

these precautions may result in serious damage to

the alternator or alternator system.

1. DO NOT attempt to polarize the alternator.

2. DO NOT short across or ground any of the termi-

nals on the alternator, except as specifically in-

structed in the “Troubleshooting Tests.”

3. NEVER disconnect the alternator output lead or

battery cables when the alternator is being driven

by the engine.

4. NEVER disconnect regulator lead from alternator

regulator terminal when the alternator is being

driven by the engine.

5. ALWAYS remove negative (–) battery cable from

battery before working on alternator system.

6. When installing battery, BE SURE to connect the

positive (+) battery cable to the positive (+) bat-

tery terminal and the negative (–) (grounded) bat-

tery cable to negative (–) battery terminal.

7. If a charger or booster battery is to be used, BE

SURE to connect it in parallel with existing battery

(positive to positive; negative to negative).

Summary of Contents for 13

Page 1: ...13 Printed in U S A 90 816462 2 695 1995 Brunswick Corporation GM 4 Cylinder MARINE ENGINES ...

Page 2: ...90 816462 2 695 0 ...

Page 7: ...1 A IMPORTANT INFORMATION GENERAL INFORMATION 72000 ...

Page 15: ...1 B 50617 IMPORTANT INFORMATION MAINTENANCE ...

Page 36: ...1 C IMPORTANT INFORMATION TROUBLESHOOTING ...

Page 74: ...2 A 50633 REMOVAL AND INSTALLATION 4 CYL ALPHA ONE DRIVE ...

Page 88: ...3 A 26790 ENGINE 181 CID 3 0L 4 CYLINDER GM ENGINE ...

Page 137: ...4 A 72079 ELECTRICAL SYSTEMS STARTING SYSTEM ...

Page 170: ...4 B 71855 ELECTRICAL SYSTEMS IGNITION SYSTEM ...

Page 197: ...ELECTRICAL SYSTEMS CHARGING SYSTEM 4 C 72078 ...

Page 237: ...4 D 72747 ELECTRICAL SYSTEMS INSTRUMENTATION ...

Page 250: ...4 E 72938 ELECTRICAL SYSTEMS WIRING DIAGRAMS ...

Page 264: ...5 A FUEL SYSTEM FUEL PUMP ...

Page 271: ...5 B 72681 FUEL SYSTEM MERCARB 2 BARREL CARBURETOR ...

Page 300: ...6 A 50628 COOLING SYSTEM SEAWATER COOLED MODELS ...

Page 309: ...6 B 73665 COOLING SYSTEM CLOSED COOLING MODELS ...

Page 325: ...C 6 EXHAUST SYSTEM MANIFOLD ...

Page 331: ...7 A 71317 POWER STEERING PUMP ...