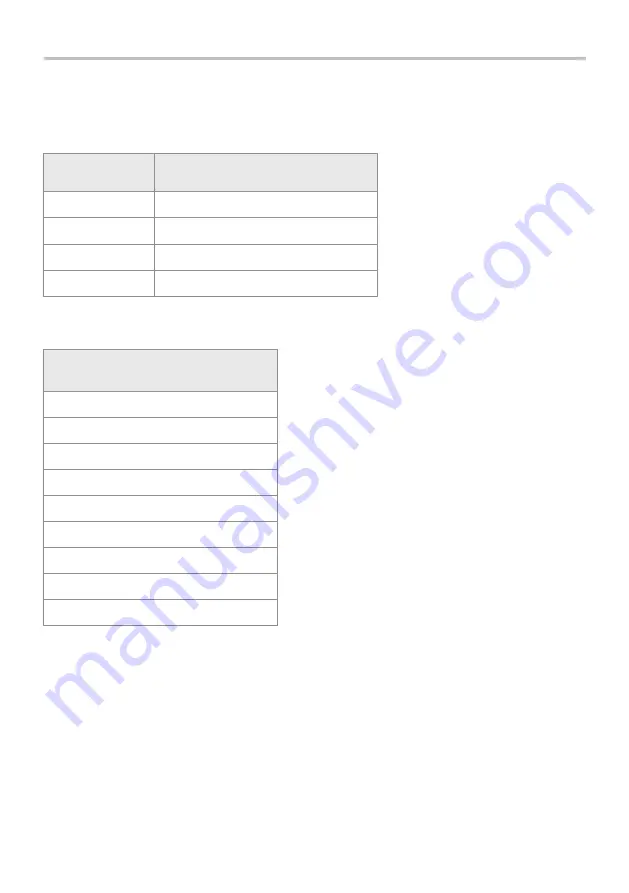

RS232 Command Responses: Information

Command: M

Response

Orbis Display Mode

Normal

Normal Mode

MaxC

Max Counter-clockwise

MaxT

Max Clockwise

MaxDual

Dual Max Screen

Command: U

Response for Torque Sensor

N.m

N.cm

mN.m

gf.cm

kgf.cm

kgf.m

lbf.ft

lbf.in

ozf.in

Command: C

The torque sensor size, in the current selected units.

Note:

‘xxxx’ will be transmitted if the torque sensor is not calibrated or has a serious fault.

Contact Mecmesin or your supplier.

page 14

It is possible to remotely interrogate your Orbis by sending the following RS232

commands. This will inform you which settings are currently configured.