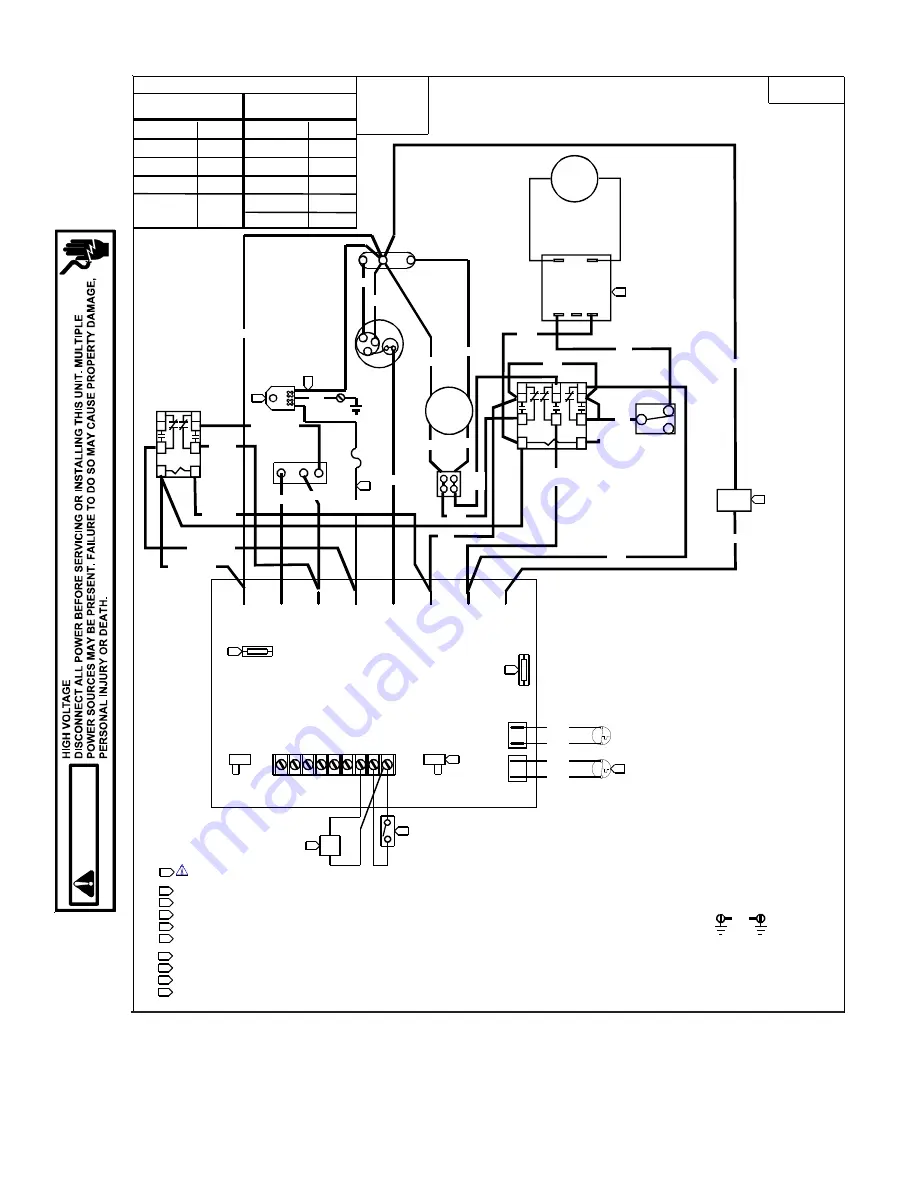

70

PTC and PTH

(Power Door - Two Stage Heat)

SCHEMATICS

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

WA

R

N

IN

G

R

C

S

RD13

YL10

F

C

H

BR35

BR34

RD33

RIBBED

WIRE

GN

2

RIBBED WIRE MUST BE CONNECTED AS SHOWN

NOTES:

WARNING: DISCONNECT POWER BEFORE SERVICING. WIRING

TO UNIT MUST BE PROPERLY POLARIZED (FOR 265V) AND GROUNDED.

REV

VALVE

SOLENOID

RD17

BK19

WIRING DIAGRAM

11179501

GN1

CONTROL

PANEL

CHASSIS

3

BR14

WH15

ON HEAT PUMP MODELS ONLY.

ON UNITS WITH REMOTE WALL MOUNTED TEMPERATURE SENSOR.

ON UNITS WITH FRONT DESK CONTROL SWITCH.

3

COMP

OD

FAN/COMP

CAP

REMOTE

TEMPERATURE

SENSOR

FRONT

DESK

SWITCH

4

HEAT PUMP W/AUXILLARY

ELECTRIC HEAT

CONNECT

R TO:

-----

G, Y/W1

G,B,Y/W1

G, W2

FUNCTION

OFF

COOL

1ST STAGE

HEAT

2ND STAGE

HEAT

COOLING UNIT

W/ELECTRIC HEAT

CONNECT

R TO:

G, Y/W1

G,B,Y/W1*

OR

G, W2

FUNCTION

COOL

1ST STAGE

ANTICIPATOR

CURRENT: .1

2ND STAGE

ANTICIPATOR

CURRENT: .2

ELECTRIC

HEATER

BK20

OFF

-----

5

REMOTE THERMOSTAT OPERATION

1

SWITCHOVER

FLOODBACK

PROTECTOR

FAN

MOTOR

LINE 1

INDOOR

SWITCH

OD TUBE

OUTDOOR

SWITCH

REMOTE/STANDARD

THERMOSTAT

CONTROL

ON OFF

MASTER

SWITCH

24 VAC

ID TUBE

24 VAC

C R G W2Y/

W1 B RS FD RC

HEATER HEATER LINE 2

COMP FAN HIGH FAN LOWR-VALVE

BK30

BK30

BK40

BK40

BK18

6

VT12

BK18 ON LINE 2 WITH FUSE SHOWN CONNECTED FOR 265V. FOR 230V, CONNECTB

POWER CORD TO LINE 2.

REMOVE FOR 265V APPLICATIONS.

REMOVE FOR NON-HEAT PUMP APPLICATIONS.

HEAT

8

7

9

FOR REMOTE OPERATION, SET SWITCH TO REMOTE POSITION

FUSE

1

2

3

4

5

6

7

8

9

10

IF SUPPLY VOLTAGE IS 208V MOVE 240V LEAD TO 208V TAP ON TRANSFORMER.

265V TRANSFORMER IS NOT SHOWN.

A

1

3

5

B

2

4

6

V T 1 9

2 S T G H T

V T 2 0

2 S T G H T

V T 1 8

2 STG HT

V T 1 7

2

S T G

H T

B R 3 6

2 S T G H T

A

1

3

5

B

2

4

6

7

8

9

TRANSFORMER

Line

240

208

CO

M

Lo

ad

POWER

VENT

MOTOR

2

3

1

BU2

(PV)

BK12

(PV)

BK11

(PV)

BK16

BK17

(PV)

BU4

(PV)

RD14

(PV)

BU15

(PV)

BU10

(PV)

WH8

(PV)

BU9

(PV)

ON/OFF

SWITCH

TERMINAL

BOARD

POWER VENT

RELAY

10

G

FAN

FAN

G