160GR Natural Gas Booster Instruction Manual

Mayekawa all rights reserved. Subject to change without notice. Lat revised in October 2007

p.4

1. Introduction

The 160GR is a compressor engineered for the natural gas booster. Provided that it will be

operated by an engine, the compressor itself has an internal speed up gear that allows

different ratios according to the required air volume.

Also, the Vi on the outlet port can be changed in 4 steps with the manual capacity control as

the standard.

2. Capacity Control Procedures

On the standard 160GR specification, the capacity control is done manually by a handle.

Turning the handle in clockwise is for loading, and turning it in counter-clockwise is for

unloading.

The slide valve for the capacity control is fully loading when it is in contact with the surface of

the variable Vi slide valve. The position of Unload is determined by the stopper equipped on

the surface of the under slide rod.

Therefore, the position of full-load of the slide valve depends on the selected Vi; therefore,

the strokes of the slide valve vary as well. The strokes of the slide valve for each Vi setting

are described below.

[CAUTIONS]

・

Although there are stopper structures on the full-load position and the minimum load

position, do not turn the handle with unnecessary force when attempting capacity control.

・

When loading, turning the handle with a relatively little force can easily move the slide valve.

When the slide valve is in contact with t

・

the variable Vi slide valve for full-load, the handle becomes heavy. Then, forcing the handle

to turn may lead to the internal damage.

・

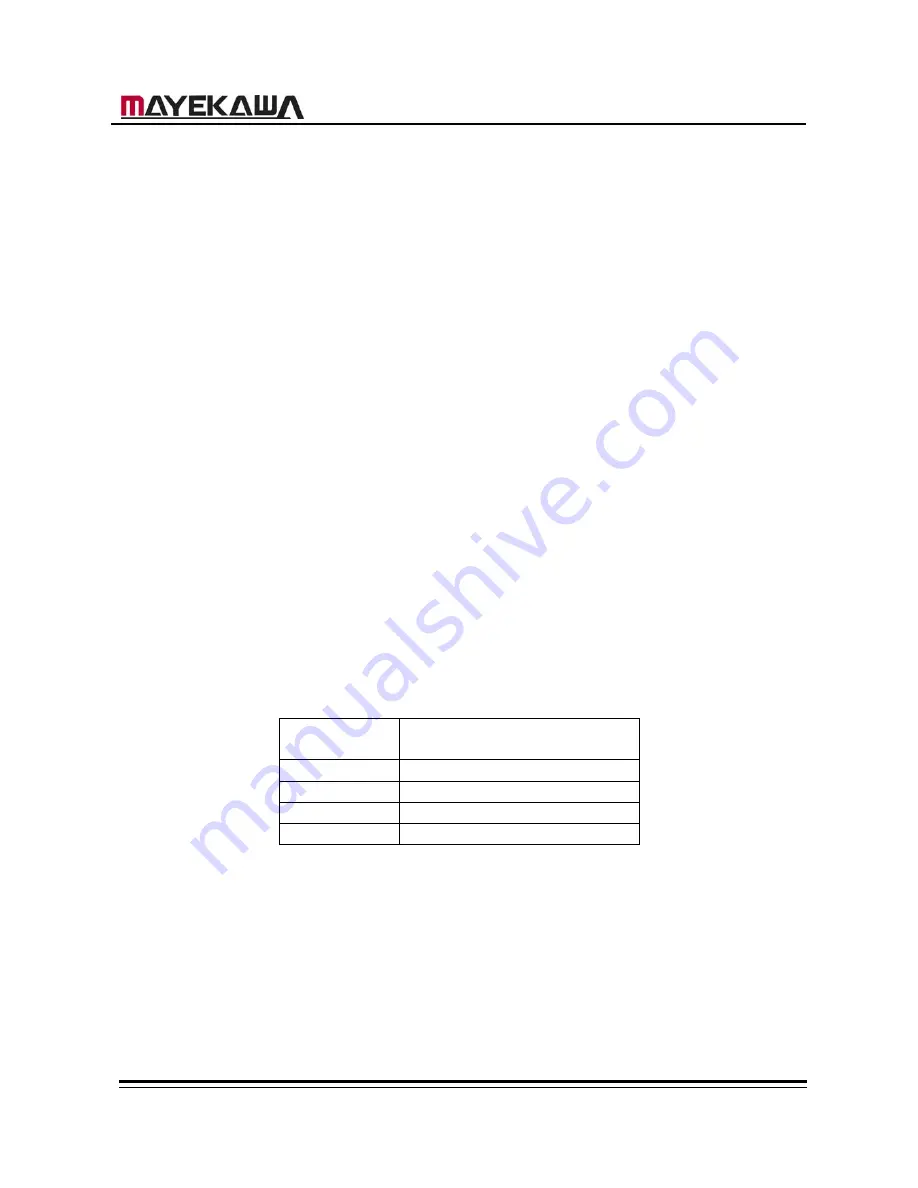

Garph2.1 Strokes for Slide Valve for Each Vi

Vi Setting

The number of rotation

Unload

⇒

Full-Load

2.3 29

‐

1/2

2.63 26

3.65 21

5.0 17-1/3

3. Variable Vi Structure

To change the Vi on the outlet port, the size of the radial outlet port needs to be changed by

moving the variable Vi supplementary slide valve on the full-load.

The variable Vi supplementary slide valve is fixed to the case by fix pins through pin holes on

the Variable Vi slide valve. The pin holes are located to accommodate the 4 different Vi

settings so that the Vi can be changed step-by-step.

On 160GR, the fix pins of the Variable Vi slide valve are attached from the outside of the case.

When the pins are removed, the interior gas will be discharged to the air. When changing Vi