44

MAX Arm/Ultra Arm V1

troubleshooting continued

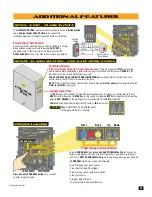

DSP Board LED

Problem Condition

Solution(s) for

Problem Condition

Normal

LED

“ID PLUG” LED is FLASHING and

board beeping

“SOLAR MODE” LED is ON

“OPEN/CLS” LED is ON

“OPEN/CLS” LED is FLASHING

“MOTOR OVERLOAD” LED is ON

“EXIT” LOOP LED is FLASHING or

contstantly ON

“SAFETY” LOOP LED is FLASHING

or contstantly ON

“CENTER” LOOP LED is FLASHING

or contstantly ON

“GATE DISABLE” LED is ON

“MAG LOCK” LED is FLASHING

“GATE TAMPER” LED is FLASHING

“12VDC” LED is OFF. “24VDC” LED

is OFF

“ON/OFF BATTERY” LED is OFF

“ANTI-TAILGATE” LED is ON

“CLOSING GATE SPEED” LEDs are

ON but gate moves slowly.

•

Insert ID PLUG module that is tethered to chassis into “ID PLUG” connector.

•

Operator is being powered by solar panel ONLY.

•

Sensor on OPEN/CLS input (photocell or edge) may have detected an obstruction while opening or

closing gate.

•

Photocell on OPEN/CLS input is misaligned with reflector.

•

Sensor on OPEN/CLS input (photocell or edge) may not be wired properly, (see ).

•

Sensor is NOT a N.C. monitored sensor that is UL 325 2018 compliant.

•

Sensor on OPEN/CLS is damaged or malfunctioning.

•

Sensor might need to be re-learned, (see ).

•

Check if gate is binding against catch post or bracket in opened or closed position.

•

Check if gate moves manually with low resistance throughout its full range of motion.

•

Check if hinges are operational and well greased.

•

Check if operator is positioned properly relative to the gate hinge, (see ).

•

Gate may be too heavy for operator (check manual for maximum gate weight for your model operator).

•

Loop fault condition: Check if EXIT loop wires are connected into to loop input connector properly.

•

Check if loop detector is inserted properly in Loop Rack slot.

•

Set unique loop detector frequency for each loop detector used.

•

Loop Detector might be defective. Replace defective loop detector.

NOTE: RENO loop detector LED’s flash as default, but function normally (ignore the flashing).

•

Loop fault condition: check if SAFETY loop wires are connected into to loop input connector properly.

•

Check if SAFETY loops are wired in series.

•

Check if loop detector is inserted properly in Loop Rack slot.

•

Set unique loop detector frequency for each loop detector used.

•

Loop Detector might be defective. Replace defective loop detector.

NOTE: RENO loop detector LED’s flash as default, but function normally (ignore the flashing).

•

Loop fault condition: check if CENTER loop wires are connected into to loop input connector properly.

•

Check if CENTER loops are wired in series.

•

Check if loop detector is inserted properly in Loop Rack slot.

•

Set unique loop detector frequency for each loop detector used.

•

Loop Detector might be defective. Replace defective loop detector.

NOTE: RENO loop detector LED’s flash as default, but function normally (ignore the flashing).

•

Check if an external device is triggering GATE DISABLE input. Disconnect devices individually to

determine possible false triggering of GATE DISABLE.

•

Maglock power is lost. Check if maglock power transformer is wired properly or needs to be replaced.

•

Switch is set to delay but no maglock is connected. Set switch to OFF

•

Gate was manually moved off of its CLOSED position causing Tamper Relay to trigger for few seconds.

•

Check for a short in wiring to connected device. DO NOT power external keypads or telephone entry to

this port (only use for radio receiver / photocell).

•

Batteries are turned OFF. Turn toroid box AC POWER switch ON and batteries automatically turn ON.

•

Anti-tailgate feature is turned ON. If this feature is not desired, turn Anti-tailgate OFF.

•

ONLY Maximum settings will turn LEDs ON. All other settings, LEDs remain OFF.

OFF

12

OFF

13

OFF

31

OFF

31

OFF

8

OFF

15

OFF

17

OFF

16

OFF

35

OFF

28

OFF

34

ON

18 or 19

ON

22

OFF

23

ON

40

1

15

10

Summary of Contents for MAX ARM

Page 2: ......