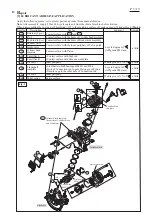

[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine (cont.)

R

epair

P 1

7

/

19

Note:

Be sure to apply Makita grease N No.2/ 4-cycle engine oil in accordance with

[3] LUBRICANT APPLICATION

.

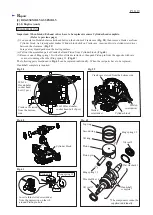

(1) Connect Piston with Crankshaft complete by inserting Piston pin into place; there is no front/back to Piston.

(2) Secure Piston pin by mounting Ring spring 12 onto each end of Piston pin.

Note:

The ring gap of Ring spring 12 can be positioned at any angle to Piston pin.

(3) Install Oil ring in the grooves of Piston; Side rail first, Spacer next, then the other Side rail.

Important:

Be sure to fit the three rings with the ring gaps at 120 degrees to one another as shown in the left of

Fig. 63

.

(4) Install Second ring first then Top ring in the groove of Piston.

Important 1:

Be sure to fit the two rings with the ring gaps at 180 degrees to each other as shown in the right of

Fig. 63

.

Important 2:

Second ring has a taper face and must be installed with the large diameter facing Oil ring. (

Fig. 64

)

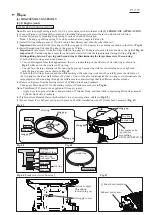

Distinguishing between Top ring and Second ring & Discriminating the larger diameter of Second ring:

If both of the two rings are new and unused,

•

You can distinguish from their appearances; there is a red marking on the side face of Second ring as shown in

Fig. 65

while not on the side face of Top ring.

•

You can face the large diameter of Second ring by placing Second ring with the red marking on your right and

with the ring gap near you as shown in

Fig. 65

.

If both of the two rings are used and the white marking of Second ring is rubbed off, carefully press the side face of

the two rings to the inner wall surface of Cylinder. You will be able to distinguish the two rings or to discriminate the

large diameter of Second ring through the differences in contact feelings that the different side faces make.

(4) Remove oil/grease from the mating surface of Cylinder block and Crankcase.

Then apply ThreeBond 1215 to the mating surface of Crankcase as shown in

Fig. 66

.

Note

: ThreeBond 1215 must not be applied to Oil supply routes.

Apply 4-cycle engine oil to the cylinder portion of Cylinder block, and then while compressing Piston rings, mount

Cylinder block onto Crankcase.

(6) Tighten eleven Hexalobular socket head bolts in a crisscross pattern. (Refer to

Fig. 58

.)

(7) Do not forget to set Exhaust port spacer in place on Muffler installation side of Cylinder head complete. (

Fig. 67

)

Fig. 67

Fig. 63

ASSEMBLING ENGINE BLOCK

Top ring

This mark can be

ignored for

assembling

EK7650H/ EK7651H.

Second ring

Fig. 64

Fig. 66

[Crankcase viewed from top]

Portion to apply

ThreeBond:

indicated in gray

Oil supply routes

Fig. 65

Top ring,

with barrel face

Second ring,

with taper face

Side rail

Side rail

Spacer

Oil ring

ring gap

ring gap

Second ring

red marking

Oil ring

ring gap

ring gap

ring gap

Side rail

Side rail

Spacer

Exhaust port spacer

Cylinder head complete