[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine (cont.)

R

epair

P 1

5

/

19

DISASSEMBLING

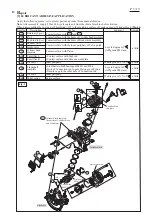

Fig. 54

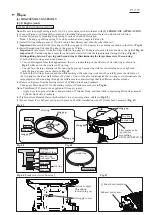

Note

: Cam gear assembly functions as automatic decompression valve system.

Valve is slightly open to release the compressed air in Engine at the starting time, before moving fly weight

by centrifugal effects. It means the insufficient setting of Cam gear assembly will cause engine stall/ extreme

reaction force at engine running due to too much load by the compressed air.

(11) Remove Pin 5 that sets Rocker arm assembly in place on Cylinder head complete. (

Fig. 54

)

Use 1R308 to push out Pin 5.

The distinction of Rocker arm assembly and Push rods (for use of the exhaust system/ intake system) enables you

shortens the repair process (Gap adjustment between Rocker arms and Retainers is even difficult, however, you can

adjust it by using 1R366. Refer to

Fig. 68

.

Important:

D

isassemble the parts in the room on Cylinder head complete before removing it and

clean the clogged portions in the following steps. You may repair successfully without

doing the step (5) and later in the next page.

(1) Remove Rocker cover complete, then push out Pin 5 on hinge for Rocker arms with 1R308 and remove Rocker arms.

(Refer to

Figs. 50

and

54

)

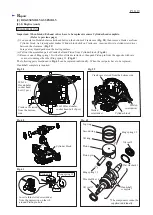

(2) Remove Spark plug. Turn Flywheel until Piston comes to the upper dead point by looking through Spark plug hole

on Cylinder head complete.

Note

: Align the rib as a mark on Flywheel with the rib on Cylinder block as drawn in

Fig. 55

.

(3) Insert a bent Lead wire #16 into Combustion chamber through Spark plug hole so that Valves do not fall into

Combustion chamber. (

Fig. 56

)

(4) While compressing Compression spring 11 by pushing Retainer with 1R003 attached with 1R389, remove Cotter by

a thin bit magnetized by 1R288.

Routes in Cylinder head complete, the upper surface on Valves and the room on Cylinder head complete can be clean

through removal of four Cotters, two Retainers, and two Compression springs 11.

Fig. 55

Fig. 57

Fig. 56

1R389

1R003

Rocker arm assembly

Exhaust

push-rod

Pin 5

Cylinder head

complete

Intake

push-rod

Intake

system

Exhaust

system

Rib on Flywheel

Rib on Cylinder block

Retainer (2 pcs.)

Cotter (4 pcs.)

[viewed from the upper side of the room]

Compression

spring 11 (2 pcs.)

Intake valve

Exhaust valve

Cylinder head complete

Note

: Intake system of Rocker

arm has to be close to

the hole of Cylinder head

complete.

the hole of Cylinder head complete

Use Cotter removal

attachment to push

Retainer.

Note

: Intake valve has to

be close to this hole

of Cylinder head

complete.