en

|

10

|

CAL-10

Operation

7.7

Lifting a trailer

In addition to lifting vehicles, this lift can be used to lift

trailers. It is important that the box or flatbed trailers

be EMPTY prior to lifting to ensure that any weight

imbalance in the load does not cause a tip-over when

the load is lifted. Also, box and flatbed trailers should

be disconnected from their tractors and should be

resting on their front supports.

Do not lift the trailer by the ICC bumper if the trailer

manufacturer has not designated it as an approved

lifting point. In preparing to lift an EMPTY box or

flatbed trailer, you should inspect the rear ICC

bumper to make sure it is not bent or damaged in any

way. If this bumper is damaged, consult the

manufacturer to determine if there is an alternate

lifting location. Roll the lift into place; make sure it is

centered in the trailer and bumper. Make sure that the

lift saddles on the lift frame fully engage (cradle) the

bottom of the bumper and that the saddle horns are

positioned front to back to ensure that the bumper is

resting on the face of the saddle and is captured

between the saddle horns—this prevents the bumper

from slipping off the saddles when lifted.

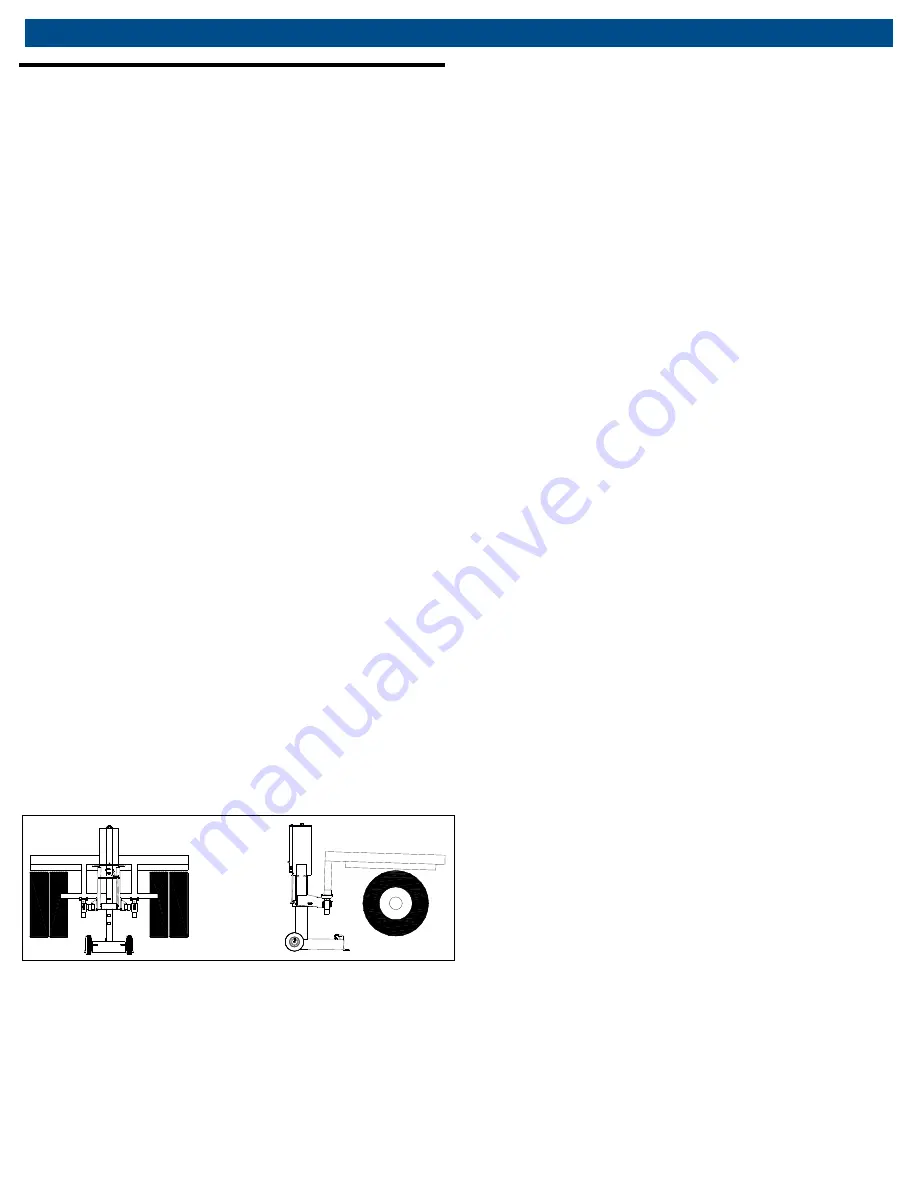

The proper lift points on an ICC bumper are directly

beneath the vehicle structure members (Fig.

4), which

connect with the frame and are approximately 34

inches apart in width. Slowly raise the lift frame to

engage the bottom of the bumper. Raise the rear of

the trailer to the desired height and then install vehicle

stands of the proper capacity to support the trailer.

Once the stands are in place, lower the trailer onto

them and then remove the lift from the work area.

Follow the instructions for lowering when work is

completed.

Fig. 4: Lifting trailer