Operation

30

© Lutz-Jesco GmbH 2020

BA-10491-02-V01

Piston diaphragm dosing pump

MEMDOS KMS LB/LA

Operating instructions

11 Operation

WARNING

Caustic burns or other burns through dosing media!

After connecting the mains supply, residual dosing media in the dosing

head can spray out.

ð

Wear the recommended personal protective equipment.

ð

Make sure that the materials you are using are suitable for the dos-

ing medium.

ð

Make sure that the lubricants, adhesives, sealants, etc. that you use

are suitable for the dosing medium.

ð

Install a leakage drain.

ð

Install pressure relief valves.

CAUTION!

Danger of automatic start up!

The dosing pump does not have an ON/OFF switch and may start to

pump as soon as it is connected to the mains supply. This means that

dosing medium can escape. Depending on the type and hazardousness

of the dosing medium, this can result in injury.

ð

Set the stroke length setting to 0 % before disconnecting it from the

power supply.

ð

Ensure that the dosing pump has been installed correctly before

connecting it to the mains supply.

PLEASE NOTE

Overheating of the motor

If the fan cover is removed or is defective, insufficient motor cooling

is provided.

ð

Before starting the dosing pump, ensure that the motor fan cover

is fitted and fully functional.

11.1 Commissioning the dosing pump

i

For initial commissioning, it is advisable to use water as the

dosing medium to check that the system is leak-proof and that

the dosing pump is functioning correctly. Check first whether

undesirable reactions could occur between the actual dosing

medium and the water.

At initial commissioning, it is advisable to prime the pump

without backpressure. For this purpose, we recommend

installing a relief valve on the discharge side of the dosing

pump.

Precondition for action:

ü

The dosing pump has been assembled and installed in accordance

with chapter 7 Installing the Dosing Pump“ on page 18, chapter 8

Hydraulic installations“ on page 19 and chapter 9 Electrical instal-

lation“ on page 22.

ü

All the mechanical fastenings have been inspected to ensure ade-

quate load-bearing capacity.

ü

The dosing head screws have been tightened with the correct torque

(see chapter 12.3 Tightening the dosing head nuts“ on page 34).

ü

All the hydraulic sections have been inspected to ensure they are ad-

equately leak-proof and that the through flow direction is correct.

ü

The drive motor and all associated additional equipment is checked

for proper connection.

ü

Personnel have read all the operating instructions and understood

them completely.

Resources required:

@

Gear oil of the viscosity class ISO-VG100 (SAE 40). The filling capacity

is about 3 l.

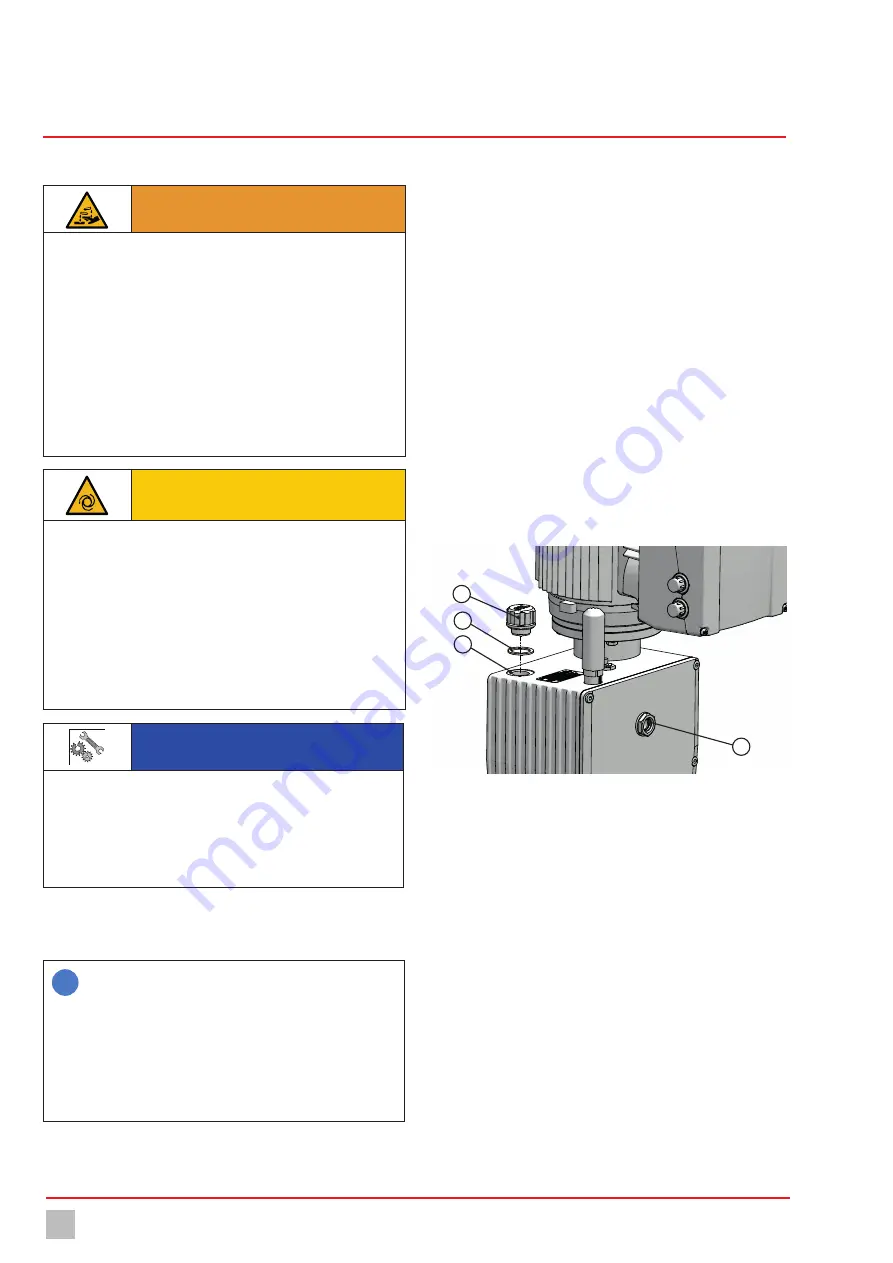

1

2

4

3

Fig. 14: Dosing pump oil inlet

Perform the following working steps:

1.

Unscrew the closing screw (1) from the oil inlet (3) and remove the

seal (2).

2.

Fill oil in the oil inlet. Check the oil level in the oil level glass (4) at the

same time. The oil level should reach to c. the middle of the oil level

glass.

3.

Place the washer seal (2) onto the oil inlet (3) and tighten up the clos-

ing screw.

4.

If present, open the pressure and suction side shut-off valves.

5.

Connect the dosing pump to the power supply.

ü

The dosing pump is commissioned.