REG. CODE

1-5302-509

MODEL N°

50778

DATE OF ISSUE

10.06.99

REVISION

00

DATE

10.06.99

ENDORSED

COMPILER TECO/ATI

38

DISASSEMBLY/REASSEMBLY

VIII

82

83

84

85

Once the head has been correctly torqued, it will not need re-

torquing unless it is disassembled again.

Before mounting, it is advisable to lubricate the bolt shanks

and under their heads with SPARTAN SAE 460 oil.

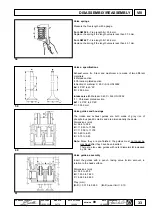

LGW 523-627 head torquing phases

The bolts must be torqued in three phases, in compliance with the

numeric order shown in fig. 82:

1st phase = 50 Nm

2nd phase = Turn the torque wrench through 90° in a clockwise

direction.

3rd phase = Continue by turning the torque wrench through 90° in a

clockwise direction.

When remounting the big-end bearings, remember to

thoroughly clean the parts and generously lubricate them to

prevent seizure when the engine is started up for the first time

Connecting rod (Big-end bearing)

After having uncoupled the connecting-rod from the crank shaft in

order to make the necessary inspections, make sure when

remounting that the two centering marks A and B are on the same

side (see fig. 83).

Tighten the big-end cap bolts to a 40 Nm torque.

Note: The big-end bearing is supplied in both the nominal value and

undersized by 0.25 and 0.50 mm.

Connecting rod, weight

To prevent imbalance, the connecting rods must be weighed before

they are replaced.

The difference in weight must not exceed 8 grams.

The connecting-rods of engines LGW 523 and LGW 627 are made

of cast iron and differ from each other as to length.

Note: For the LGW 523 AUTOMOTIVE version, weigh the pre-

assembled connecting rod, piston and pin. The margin of

error must be within 8 grams.