REG. CODE

1-5302-509

MODEL N°

50778

DATE OF ISSUE

10.06.99

REVISION

00

DATE

10.06.99

ENDORSED

COMPILER TECO/ATI

46

LUBRICATION CIRCUIT

IX

It is important to wear protective goggles when compressed air

is used during repairs.

Wash the parts with degreasing and detergent liquid.

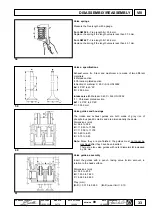

Internal suction strainer and engine oil return tube

Wash the internal suction strainer 1 and the engine oil return tube 2;

blow them with compressed air.

Replace retention rings 3 and 4 .

Tighten the bolts to a 10 Nm torque when the sump is remounted.

Tighten the oil drain plug to a 40 Nm torque.

Oil pump

Oil pump flow rate test at 1000 r/min with oil at 80°C.

Engine Flow rate (l/min) Pressure(bar)

LGW 523 - LGW 627

4 to 4.3 3 to 3.5

Flow rate test at 3600 r/min with oil at 80°C

Engine Flow rate (l/min) Pressure(bar)

LGW 523 - LGW 627

19.3 4 to 4.5

Oil pump, play between rotors

Measure play A between the teeth as shown in the figure. The max

value is 0.171 mm; wear limit play 0.250 mm.

Consult figs. 35, 35a and 36 when disassembling and remounting.

Oil pressure regulating valve

Components:

1 Valve

2 Spring

3 Seal

4 Plug

Spring length = 27.50 to 27.75 mm

Blow the valve housing with compressed air and thoroughly clean all

parts before remounting them.

Note: The valve begins to open at a pressure of 4.5 to 5.5 bar at

1000 r/min.

116

112

113

115

114