COMPILER TECO/ATL

REG. CODE

1-5302-509

MODEL N°

50778

DATE OF ISSUE

10.06.99

REVISION

00

ENDORSED

DATE

10.06.99

43

DISASSEMBLY/REASSEMBLY

VIII

105

106

104

It is important to wear protective goggles when compressed air

is used during repairs

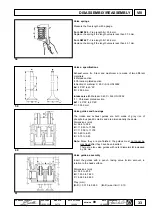

Crank shaft, lubrication ducts

A = Crank shaft LGW 523

B = Crank shaft LGW 627

Place the shaft in a bath of degreasing and detergent fluid.

Remove the plugs and clean ducts 1 and 2 or

3 and 4 with a

pointed tool. Blow with compressed air.

Fit the plugs back into their housings and check for tightness.

Note: The crank shaft of engine LGW 523 with aluminium cylinder

block cannot be interchanged with that of the cast iron

cylinder block since the counterweights are different.

Crank shaft, main journal and crank inspection

Use a micrometer for exteriors.

Diameters of main journal and big-end journals

Dimensions:

A = 47.984 to 48.000

wear limit = 47.900

B = 39.984 to 40.000

wear limit = 39.900

The diametrical values of the main journal and big-end journals are

the same for all the engines in the series ( LGW 523, LGW 627).

Inner diameters of main and big-end bearings

Dimensions (mm):

C = 48.041 to 48.091 wear limit = 48.130

D = 40.021 to 40.050 wear limit = 40.100

The given dimensions refer to tightened bearings. Consult fig. 83 for

the big-end tightening torque and fig. 93 for the main bearing cap

tightening torque. Play between bearings and corresponding pivots

(mm) see figs. 107, 108.

(C-A) = 0.041 to 0.107 wear limit = 0.230

(D-B) = 0.021 to 0.066 wear limit = 0.130

Note: There are 0.25 and 0.50 mm inner diameter undersizes for

both main and big-end bearings.

108

107