- 44 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

96

8

97

.

M

.

P

.

R

r

e

w

o

P

)

P

H

(

W

k

h

W

k

/

g

)

h

P

H

/

g

(

2

-

5

3

4

D

L

2

1

0

0

0

3

)

9

1

(

7

9

,

3

1

N

6

7

-

4

7

)

8

0

2

-

3

1

2

(

2

8

2

-

0

9

2

)

3

,

7

1

(

2

7

,

3

1

B

N

3

9

-

1

9

)

6

8

1

-

1

9

1

(

4

5

2

-

9

5

2

1

B

/

2

-

5

3

4

D

L

2

1

0

0

6

3

)

0

2

(

7

,

4

1

N

8

6

-

6

6

)

1

2

2

-

7

2

2

(

0

0

3

-

9

0

3

)

8

1

(

3

2

,

3

1

B

N

0

8

-

8

7

)

8

0

2

-

4

1

2

(

3

8

2

-

1

9

2

2

-

5

7

4

D

L

2

1

0

0

0

3

)

5

,

1

2

(

8

,

5

1

N

5

7

-

3

7

)

6

8

1

-

1

9

1

(

3

5

2

-

0

6

2

)

2

,

0

2

(

5

8

,

4

1

B

N

4

8

-

2

8

)

7

7

1

-

1

8

1

(

0

4

2

-

6

4

2

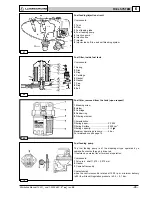

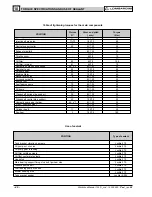

Injection pump delivery setting with engine at the torque

dynamometer

1) Bring engine to idling speed

2) Unscrew delivery limiting device C (see pic. 94)

3) Bring engine to the power and r.p.m. required by the manufacturer

of the device.

4) Check that consumption falls within the table specifications (see

below).

If consumption is not as indicated change balance conditions at the

torque dynamometer by varying the load and adjusting the governor.

Under stable engine conditions check consumption again.

5) Tighten limiting device C until the engine r.p.m. decreases.

Lock the limiting device by means of lock nut.

6) Release brake completely and check at what speed the engine

becomes stable.

Speed governor should comply with the requirements of the class

indicated by the manufacturer of the device.

7) Stop the engine.

8) Check valve clearance when the engine has cooled down.

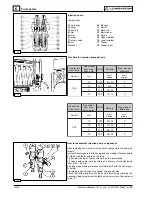

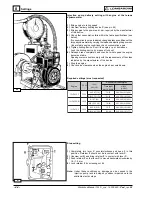

Required settings (most requested)

Stop setting

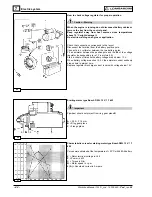

1) Completely turn lever C counterclockwise and keep it in this

posi-tion. Retainer F should not be in contact with lever C.

2) Unscrew nut G and bring retainer F in contact with lever C.

3) Push retainer F so that lever C is moved backwards clockwise by

1.0÷1.5 mm.

4) Lock retainer F by screwing nut G.

Note: Under these conditions no damage can be caused to the

injection pump rack rod stops by sudden impacts due to the

available electric stops.

Settings

Specific fuel consumption

Time (sec)

per 100 cm3

Engine