- 39 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

81

82

6

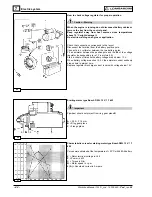

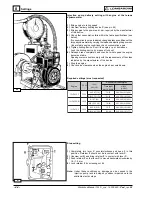

Injector setting

Connect injector to a hand pump and check that setting pressure is

210÷220 bar (258÷270 bar for EPA engines); make the required

adjustments, if any, by changing the shim over the spring.

When replacing the spring, setting should be performed at a 10 bar

greater pressure (220÷230 bar for standard engines, 268÷280 bar for

EPA engines) to allow for bedding during operation.

Check needle valve sealing by slowly moving hand pump until

approximately 180 bar.

Replace nozzle in case of dripping.

Fuel system

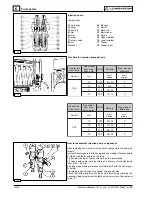

Injector, for EPA engines

Components:

1 Injector housing

7 Nozzle

2 Intake fitting

8 Cup

3 Shim

9 Needle valve

4 Spring

10 Sump

5 Pressure rod

11 System duct

6 Taper pin

12 Overflow pipe

When refitting tighten ring 8 nut at 50 Nm.