- 36 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

3

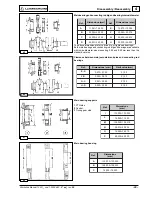

m m

mm

3

n

o

t

w

e

N

m

m

0

5

,

0

0

1

0

0

5

1

6

2

÷

3

2

3

2

1

0

0

5

8

÷

4

3

0

0

5

1

5

6

÷

7

5

-

0

1

0

0

5

4

1

÷

0

1

3

R.P.M.

72

6

71

n

o

t

w

e

N

m

m

0

5

,

0

0

1

0

0

5

1

2

3

÷

9

2

3

2

1

0

0

5

5

1

÷

1

1

3

0

0

5

1

2

7

÷

4

6

-

0

1

0

0

5

4

2

÷

0

2

3

3

m m

mm

3

R.P.M.

73

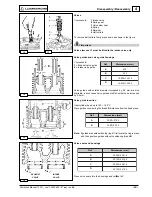

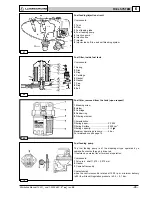

Injection pump

Components:

1 Pump body

10 Plunger

2 Fitting

11 Barrel

3 Seal ring

12 Rack rod

4 Filler

13 Sector gear

5 Shim

14 Spring

6 Spring

15 Upper retainer

7 Delivery valve

16 Lower retainer

8 Seat

17 Tappet

9 Gasket

18 Tappet roller

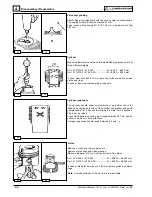

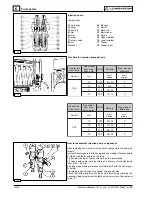

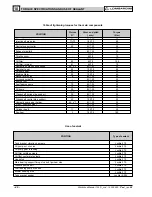

Test data for injection pump delivery

Delivery

Max. plunger

difference

Rod stroke

from max.

deliv. point

Control rod

max. force

stroke

stroke

Delivery

Max. plunger

difference

Rod stroke

from max.

deliv. point

Control rod

max. force

stroke

stroke

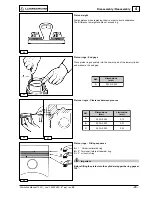

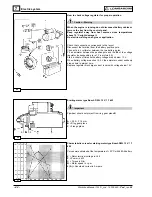

How to reassemble injection pump components

After replacing the worn-out components, reassemble the pump as

follows:

Introduce sector gears into the pump body by making reference points

C match with the B points on the rack.

Fix barrels with the eccentric screws F on the pump body.

Fit valves with seats, springs, tillers and delivery unions tightening

them at 35 ÷ 40 Nm.

Fit plungers by making reference points E match with the sector gear

D points.

Fix retainers and springs; lock tappet with special stop.

Check that both plungers have the same delivery by performing the

necessary measurements at the test bed; it delivery is not the same set

screw F.

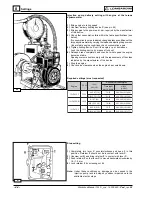

Fuel system