- 38 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

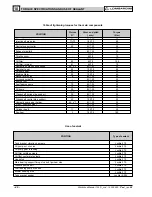

78

79

6

80

2

/

5

3

4

D

L

2

1

0

0

0

3

°

1

±

°

3

2

0

7

5

.

3

°

2

2

4

9

8

.

3

°

3

2

2

3

2

.

4

°

4

2

1

B

-

2

/

5

3

4

D

L

2

1

0

0

6

3

°

1

±

°

3

2

0

7

5

.

3

°

2

2

4

9

8

.

3

°

3

2

2

3

2

.

4

°

4

2

2

-

5

7

4

D

L

2

1

0

0

0

3

°

1

±

°

1

2

1

6

9

.

2

°

0

2

8

5

2

.

3

°

1

2

0

7

5

.

3

°

2

2

A

P

E

2

-

5

7

4

D

L

2

1

0

0

0

3

°

1

±

°

0

2

6

7

6

.

2

°

9

1

1

6

9

.

2

°

0

2

8

5

2

.

3

°

1

2

1

2

4

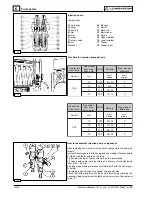

Injector, for standard engines

Components:

1 Intake fitting

8 Needle valve

2 Nozzle holder

9 Fixing flange

3 Shim

10 Taper pin

4 Spring

11 Gasket

5 Pressure rod

12 System duct

6 Intermediate flange

13 Sump

7 Nozzle

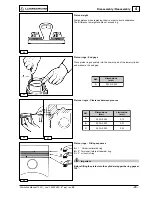

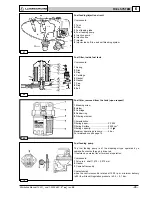

Fuel system

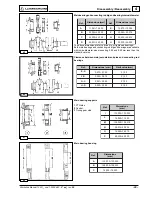

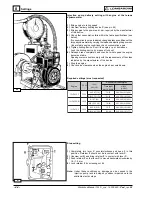

Piston lowering

value (mm)

R.p.m.

Advance

degrees

Engine type

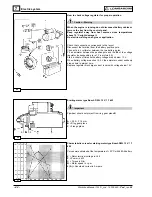

Fasten capillary tube 4 on the delivery union of the cylinder on which

the valve lowering tool is installed.

Turn the flywheel and alternatively fill the capillary tube until the fuel

flows out.

Turn the flywheel clockwise (pic. 77) and, during the compression

phase, turn it slowly.

Stop as soon as the fuel starts moving inside the capillary tube.

Press the valve by turning lever 1 until it meets the piston and using

dial indicator 2 read the piston position in millimetres before the TDC.

Use the transformation chart to find out the correspondence between

the millimeters measured with dial indicator 2 and the degrees.